- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining titanium

Results for

Machining titanium - Import export

RPJM SOLUTIONS

Portugal

We specialise in CNC precision machining of metal alloys, composites and industrial plastics, as well as welding, for the production of parts for a wide range of industrial applications, with project development and assembly if required.

Request for a quote

STARRAG GMBH

Germany

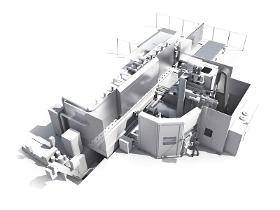

High performance simultaneous 5 axis machining center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The finish is brushing.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

1.Part material: titanium 2.Machining type: precision cnc turning 3.Surface:Polishing ,Ra0.8 4.Tolerance:+/-0.05mm 5.Application : medical equiment parts 6.Quality,reliability and long product life.

Request for a quote

RPJM SOLUTIONS

Portugal

We specialise in CNC precision machining of metal alloys, composites and industrial plastics, as well as welding, for the production of parts for a wide range of industrial applications, with project development and assembly if required.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC machining titanium part

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC milling.

Request for a quote

APD MAQMASTER

Spain

Titanio, Poseidone's older brother, is a robust machining center that, in its version with grippers, allows for loading sections of up to 300mm x 2600mm. It is a center dedicated to multiple pieces, which in addition to having everything necessary for machining, has a 500mm blade with a 4kw motor, to section panels of considerable size and a CNC gantry for various applications, while still being in the industrial sector.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

titanium stud manufactured by CNC turning and milling on sliding head multi-axis CNC lathe 2-step surface turned, 2 grooves milled on the opposite sides material: titanium, ASTM commercial pure grade 2 (China GB TA2) size: outer diameter 12.7 +/- 0.05 mm, inner diameter 10.31 +/- 0.10 mm, height 9.53 +/- 0.10mm unit weight: 2.3 g usage: for assembly of tri-sensor packing: each piece placed in plastic tray, then packed into carton

Request for a quote

STARRAG GMBH

Germany

The ECOFORCE Ti 9/13 is the modular solution leading in machining titanium structures Full range of pallet sizes from the ECOSPEED series available between 1 x 4 m up to 2.5 x 8 m 2D head made for Timachining with 8,000 rpm / 940 Nm (S1) or 5,600 rpm / 1,300 Nm (S1) known 100 bar coolant supply for longer tool life Modular concept with multitude of options for all customer needs

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

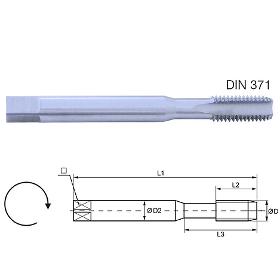

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For titanium Material of product: HSSE Surface treatment: no For materials: Pure Titanium and Titanium alloy Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H The geometrie and base material (HSSK powder metal) is made to cut into titanium and titanium alloy. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Traditionally, perforated tube is manufactured through a lengthy operation starting with flat strip metal that goes through four stages of processing before completion. This is a time-consuming and costly procedure with chances for complications throughout the process. We’ve innovated the way perforated tube is processed by perforating pre-formed tube in one operation. This saves you time, money and hassle as it eliminates the long process and any production issues that can occur, while providing a visually enhanced product. Our five perforating machines can perforate stainless steel, titanium and aluminium tubes from 38mm to 101.60mm⌀, in lengths up to 750mm long. The specialist tool design allows tube perforation in various patterns that can be tailored to produce bespoke and unique patterns and shapes.

Request for a quote

TITANIUM ENGINEERS LTD

United Kingdom

Titanium 6Al-2Sn-4Zr-6Mo (6246) Bar and Machined Components Advantages of Titanium 6246: • Conforms to NACE MR 0175/ISO 15156 • Superior corrosion resistance in oilfield environments • Low density/ very high strength-to-weight ratio • Low modulus of elasticity • Low thermal expansion • Non-magnetic • Good fatigue resistance • Can be heat treated to higher strength levels than Ti 6Al-4V (minimum 1040 MPa / 150 ksi) • Good high temperature mechanical properties Call us today for a quotation on +44(0)1675 464200 or email contactus-UK@titaniumengineers.com

TITANIUM ENGINEERS LTD

United Kingdom

Titanium 6Al-4V (Grade 5) in Bars and Machined Components Advantages of Titanium 6Al-4V: • Good corrosion resistance in seawater applications • Low density/ high strength-to-weight ratio • Low modulus of elasticity • Low thermal expansion • Non-magnetic • Good fatigue resistance • Good high temperature mechanical properties Call us today for a quotation on +44(0)1675 464200 or email contactus-UK@titaniumengineers.com

TITANIUM ENGINEERS LTD

United Kingdom

Titanium Beta-C (Grade 19) Bars and Machined Components Some advantages of Titanium Beta-C: • Excellent corrosion resistance • Can be heat treated to yield strength levels above 1170MPa (170 ksi) • Stronger than titanium alloys 6Al-4V and 6Al-2Sn-4Zr-6Mo • Conforms to NACE MR 0175/ISO 15156 • Excellent fatigue resistance • High strength-to-weight ratio Call us today for a quotation on +44(0)1675 464200 or email contactus-UK@titaniumengineers.com

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Machining titanium - Import exportNumber of results

17 ProductsCategory

- Pipes and tubes, titanium (4)

- Handling - Machines & Equipment (2)

- Machine tools, metal machining - parts and accessories (2)

- Moulds, precision (2)

- Aluminium and aluminium alloys (1)

- Fire extinguishers (1)

- Machine tools - metal machining (1)

- Mechanical engineering - custom work (1)

- Perforation of steels and metals (1)

- Pipes and tubes, stainless steel (1)

- Steel & Metal Transformation (1)

- Tools & Hardware (1)