- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining centre for metals

Results for

Machining centre for metals - Import export

EMSIL TECHTRANS SRL

Romania

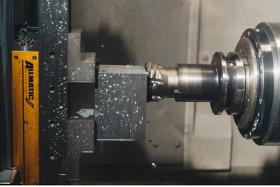

Wide selection of machining centres. CNC machine tool is an advanced computer-controlled machine that can be used for performing different machining operations

Request for a quote

SIRRIS

Belgium

How practically feasible or realistic is an idea? Sirris can help you find out, and not just by offering advice. All the innovative solutions we develop together with you are also put to the test in an industrial setting, either on your behalf or in conjunction with you. Our high-tech infrastructure will always enable you to find out exactly where you stand. A few examples of our infrastructure A metal machining centre, guaranteeing micron precision Europe's largest climate chamber Cobots deployed in a flexible, robotised, machining cell Europe's most highly diversified additive manufacturing machine park Hybrid PVD or HiPIMS and aerosol jet printing Microproduction (machining, EDM, injection moulding , etc.). An application lab for Incremental Sheet Forming (ISF) Testing laboratories for materials & products analysis...

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"With the help of our rich machine park and well-experienced engineers, we can answer your custom design machine part needs. Please don't hesitate to ask for the price."

Request for a quote

AGS - CNC MACHINING UNIP. LDA

Portugal

HAUTEUR - AVEC PRISE 200MM LARGEUR - 270MM VANNE PAPILLON

Request for a quote

AGS - CNC MACHINING UNIP. LDA

Portugal

HAUTEUR - AVEC BOUCHON 250MM LARGEUR - 310MM VANNE DE CONTRÔLE

Request for a quote

GSW SCHWABE AG

Germany

A perfect combination of space savings and dynamics: the GSW Compact Feed Lines Our Compact Feed Lines are an ideal answer to the challenge of a constraint floor and necessity to process thick materials. Marrying the processes of leveling and indexing into one Feeder-Straightener machine allows for a complete Feed Line with only two individual machines and thus greatly reduces the necessary length. Additionally, the decoupling of the coil mass from the indexing process – achieved through a short loop between Coil Reel and Feeder-Straightener – enables dynamic feeding despite the compact footprint. And, if cross-sections are especially big, the loop can be spared completely, creating yet more space. One more advantage, virtually a by-product out of their very nature, is the quicker set-up of our Compact Feed Lines. This elevates them to not only space- but also time-savers!

Request for a quote

GSW SCHWABE AG

Germany

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC punching: sheet up to 4mm 1250x3000 mm; - CNC bending up to 3000 mm 100T; - Sheet rolling up to 4 mm, width 1500 mm; - CNC milling with 3-axle by vertical machining centres of up to 2000x500x600 mm; - CNC milling with a 4-axle vertical machining centre of up to 2000x540x440 mm; - CNC turning, rod up to D65 mm; - CNC turning by vertical machine up to D250, L160; - Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000; - Flat grinding: 200x500mm.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC punching: sheet up to 4mm 1250x3000 mm; - CNC bending up to 3000 mm 100T; - sheet rolling up to 4 mm, width 1500 mm; - CNC milling with 3-axle by vertical machining centres of up to 2000x500x600 mm; - CNC milling with a 4-axle vertical machining centre of up to 2000x540x440 mm; - CNC turning, rod up to D65 mm; - CNC turning by vertical machine up to D250, L160; - Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000; - Flat grinding: 200x500mm.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC punching: sheet up to 4mm 1250x3000 mm; - CNC bending up to 3000 mm 100T; - Sheet rolling up to 4 mm, width 1500 mm; - CNC milling with 3-axle by vertical machining centres of up to 2000x500x600 mm; - CNC milling with a 4-axle vertical machining centre of up to 2000x540x440 mm; - CNC turning, rod up to D65 mm; - CNC turning by vertical machine up to D250, L160; - Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000; - Flat grinding: 200x500mm; - External thread rolling: M8, M10, M12, W16.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Aluminum Alloy Parts by Precision CNC Machining Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

High precision steel shaft/splined shaft for connecting/coupling shafts 1) Customer’s drawing or samples accepted. 2) Excellent and high quality control. 3) Prompt delivery. 4) Competitive price. steel shafts 1) Material: Carbon steel , Stainless steel,brass or as per customer’s requirements. 2) Diameter: 0.3-80mm, tolerance:+/-0.005mm. 3) Roundness: 0.003mm. 4) Roughness: Ra0.04. 5) Straightness: 0.005mm. 6) Hardness: HRC/HV. 7) Precision: Grade 6. 8) Length: Max.700mm. 9) Heat treatment:Point hardening,quenching hardening. 10) Surface treatment: zinc plating, nigrescence,chrome plating, nickel plating etc. 11) OEM Service: Providing us the drawing with detail information. 12) Offering products with speciality, quality and efficiency. 13)Package:Plastic bag inside and outer standard carton , pallet.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Description: •Precision machined components, Machining service, CNC precision machining, Stainless steel precision machined parts manufacturer •Material to process: aluminum, stainless steel, carbon steel, brass •Precision: 0.010-0.002mm •Equipments: CNC lathe, processing center, miller, cylindrical bore grinder, surface form grinder, punching machine, etc. •Surface treatment: zinc, nickel, anodized, polishing •Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. •We are able to supply Precision machined components, mechanical parts machining, surface treatment such as anodize and plating according to our customers’ requirement. •Packaging details: inner plastic bag, outer standard carton box •Delivery time: 25-35 days Notes: we manufacture precision machined components in compliance with customer’s designs. The products are shown here ony to present the

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Machining Parts ● Materials for CNC Precision machining parts We can process product materials are: An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from1050-7475), commonly used are: 2011,5052,6061,7075, etc. (2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000 (3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades(JIS grade corresponds to the basic, together with the SUS can):201,301,303,304,314,316,420,430,630 Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15) ● CNC Precision machining parts accuracy Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm ● Maximum size of Precision parts suit to CNC machining

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Metal Shaft Motor shaft, Fan shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part. Mechanical precision part/Mechanical precision part. 1) Material: Carbon steel, Stainless steel, brass or as per customer’s requirements. 2) Roundness: 0.001mm 3) Roughness: Ra0.04 4) Straightness: 0.001mm 5) Length: Max. 1000mm 6) Heat treatment: Point hardening, quenching hardening 7) Surface treatment: Zinc plating, nigrescence, chrome plating, nickel plating etc. 8) OEM Service: Providing us the drawing with detail information. 9) Offering products with speciality, quality and efficiency. 10) Package: Plastic bag inside and outer standard carton, pallet. According to client’s demand. Specifications for CNC METAL SHAFT

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROBALT ENGINEERING OÜ

Estonia

The production of cnc turning parts is a quite difficult process that requires a lot of attention, excellent machinery and experienced specialists. Our customers set high requirements for the production of their metal parts. Today, various metal parts almost can’t be produced without applying this or that type of additional machining process.

Request for a quote

INGENIERIA IRADI S.L.

Spain

Our team of engineers thoroughly researches each project and designs the most appropriate solution for each customer. The technical office works in accordance with the needs of the customer or independently to meet a stated requirement. We offer complete solutions from design, manufacturing and quality control to on-site commissioning. We have a flexible structure, a dependable supplier network, technical training, and in-depth project knowledge. Our highly qualified technical department works with advanced 3D design programmes and we optimise our designs by means of finite element calculations, eliminating uncertainties and ensuring the correct functioning of each application.

Request for a quote

INGENIERIA IRADI S.L.

Spain

Machining according to drawing, from prototypes and unit batches to small and medium-sized production runs We specialize in serial production and machining of all components that require machining on lathes, milling machines, and machining centres.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Each our component is individually handled in complete care and tested with the latest measuring devices - Mitutoyo. Specialized in smaller productions has its own advantages. We individually devote ourselves to our partners. We support you by: - before production, we review the technical documentation and implement possible changes, - we have a larger amount of material in stock which guarantees us an immediate start of production and quick delivery of a new spare part, - all products are inspected, deburred and hand polished before release. The components are checked to ensure that they fit properly and that the external product is compatible. All dispatched products are functional and visually sophisticated. Which leads to more affordable and better quality of the end-product, and consequently greater satisfaction of our partners.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Our focus is on quality manufactured and quick delivery times while keeping a competitive pricing level. We are working with various materials like aluminium alloys, plastic, metal and steel. Our technically advanced metal processing services with 3- and 5-axis CNC milling work allow us to meet clients’ specific requirements. We do our best to ensure that the services are provided with quality and in the shortest possible time. We support you by having more than 3 tons of material in stock, which guarantees us an immediate start of production. Which results in shorter delivery times and immediately providing you a new spare part. We are being part of many development companies. We have become an important part of: ●control lines, ●automatic assembly, ●robotic grippers, ●independent stations, ●pallet systems, ●pneumatic systems ●and production lines.

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER!

Request for a quote

CHESTER MACHINE TOOLS UK

United Kingdom

High performance CNC Machining Centres with a choice of Siemens or Fanuc Control Systems. Chester's range of high quality CNC Machines, provide optimal precision performance. Our Mini Centre size is ideal for educational environments and small workshops, whilst the U320 is an industrial sized machine.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, gripper clamping or pull-down clamping are all possible -TITAN 2 K – ideal for use on five-axis machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -High-pressure spindle with power intensification. Clamping force does not slacken -Enlarged clamping span for secure clamping of unmachined parts -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER -Clamping near to neutral axes -Clamping jaws of forerunner are compatible

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -Ideal for use on 5-axis machining centres -Reliable and fast clamping of unmachined parts, flame-cut and sawn materials with gripper jaws -Clamping of parallel pre-machined workpieces with optional step jaws -Gripper studs suitable for materials with a strength of up to approx. 1000N/mm² Product features: -Optimum accessibility for 5-sided machining thanks to the combination of compact base and large clamping width -Stamping and clamping in a single process, in the working area itself, without any additional accessories -The movable/pivot support jaw allows different workpiece contours to be clamped -Gripper studs can be changed without tools and are easy to adjust by hand -Operation with a torque wrench – max. 30 Nm -High-pressure spindle with power intensification

Request for a quote

BIESSE UK

United Kingdom

WinLine 16 is Biesse's new NC multi-centre for the production of doors and windows, designed for artisans and small industries aiming to increase production and for medium and large industries who need to produce small batches of unusual size or remakes. The system produces both standard and special doors and windows with the utmost simplicity while the operator handles other tasks; the machine only takes up a small area and handles the loading, unloading and positioning of pieces autonomously and with extreme precision.

OSMAK RULO MAKINA SAN. VE LTD.STI

Turkey

Defense industry is one of the most important element for every single nation. We are proud to serve Turkish defense industry with costum design machining parts. Osmak is your reliable solution partner of many type of custom design machining parts. Please do not hesitate to contact us to place your order.

Request for a quote

BOGRAMA AG

Switzerland

The most universal and most sold model by far for the mid capacity range to 10,500 cycles/h. Simple operation from touchscreen Integrated controller for infeed hole punching Available in two working widths.

Request for a quoteResults for

Machining centre for metals - Import exportNumber of results

38 ProductsCountries

Category

- Machine tools - metal machining (17)

- Steels and metals - machining (13)

- Machine tools, metal machining - parts and accessories (11)

- Metal straightening machines (4)

- Coil winders (2)

- Metals - Machines & Equipment (2)

- Punching machine tools (2)

- Handling - Machines & Equipment (1)

- Laser - cutting and welding machines (1)

- Woodworking - machinery and equipment (1)