- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines for manufacturing parquets

Results for

Machines for manufacturing parquets - Import export

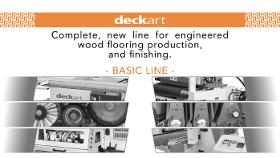

DECK ART MACHINES

Serbia

We are engineered wood flooring manufacturing experts, through the years of experience in this branch of industry we were able to develop unique, dedicated machinery, with our technology, and to offer these unique machines and services that will allow our customers to produce quality finished products. All of the lines that we are able to offer consist of all the machines needed for getting the final product. From cutting the core material, gluing of wear layers, profiling, sanding to final finishing of flooring with oils, stains or varnish (lacquer finish) as well as LED UV Oils and LED UV Varnishes. - We guarantee high quality finished product developed by our many years of experience in engineered wood flooring manufacturing. - Every line can be specially tailored upon buyers special needs and requests. - Depending on the buyer's needs every line always has an option of automation. - When offering new lines we include complete information on technology of production

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The Systems comprise the entire casting process: Preparation of the material components resin and hardener (conveying, formulation, homogenization, degassing), production of the reactive mix and casting of the parts under vacuum/atmosphere. Any resin system can be processed, including fillers, and also with strongly disproportional mixing ratios.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1 Accuracy:99.9% according to the quantity with fiber counting which is a much big range of direct, fast, and stable reaction speed.End weighing director is optional for higher accuracy by rejecting the out tolerance dose. 2 Capacity: About 100~300 pcs /min per plate according to the exact product. 3 Durable: Lower malfunction rate and Lifetime of About 10 years. 4 Versatility: The same one torsional vibrator is able used for a certain range of products in different sizes and shapes. Ergonomic condition: ergonomic condition operation area for the parts manually feeding which is unworkable with the machine. Feeding: Staff is convenient for feeding enough parts into the torsional vibrator which the height is about 800~900mm above the grand.A fully automatic elevator or hopper is optional. Quickly format change: remaining parts will be cleared in 5 min by pressing one button. Lower Noise and surface wear with the specific glue on the surface of the torsional vibrator.

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Machines for manufacturing parquets - Import exportNumber of results

3 ProductsCountries

Company type