- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine techniques

Results for

Machine techniques - Import export

BULUT CNC MACHINING

Turkey

Experience unparalleled precision with BULUT CNC MAKINA's bespoke CNC projects, meticulously crafted in Turkey. Committed to excellence, we specialize in tailoring components to match your unique requirements. From intricate machinery parts to bespoke project elements, our team employs cutting-edge CNC milling, turning, and machining techniques for optimal solutions.we redefine excellence in the realm of brass machined parts manufacturing. With a relentless commitment to quality, innovation, and customer satisfaction, we stand as the premier destination for businesses seeking top-tier brass components for their diverse applications.

Request for a quote

BULUT CNC MACHINING

Turkey

Experience unparalleled precision with BULUT CNC MAKINA's bespoke CNC projects, meticulously crafted in Turkey. Committed to excellence, we specialize in tailoring components to match your unique requirements. From intricate machinery parts to bespoke project elements, our team employs cutting-edge CNC milling, turning, and machining techniques for optimal solutions.

Request for a quote

BULUT CNC MACHINING

Turkey

Experience unparalleled precision with BULUT CNC MAKINA's bespoke CNC projects, meticulously crafted in Turkey. Committed to excellence, we specialize in tailoring components to match your unique requirements. From intricate machinery parts to bespoke project elements, our team employs cutting-edge CNC milling, turning, and machining techniques for optimal solutions.We redefine excellence in the realm of brass machined parts manufacturing. With a relentless commitment to quality, innovation, and customer satisfaction, we stand as the premier destination for businesses seeking top-tier brass components for their diverse applications.

Request for a quote

BULUT CNC MACHINING

Turkey

Experience unparalleled precision with BULUT CNC MAKINA's bespoke CNC projects, meticulously crafted in Turkey. Committed to excellence, we specialize in tailoring components to match your unique requirements. From intricate machinery parts to bespoke project elements, our team employs cutting-edge CNC milling, turning, and machining techniques for optimal solutions..We redefine excellence in the realm of brass machined parts manufacturing. With a relentless commitment to quality, innovation, and customer satisfaction, we stand as the premier destination for businesses seeking top-tier brass components for their diverse applications.

Request for a quote

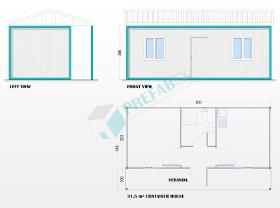

PREFABEX MODULAR BUILDING SOLUTIONS

Turkey

Using the latest techniques and machines, Prefabex presents a wide range of portable house Container buildings. Our modular house containers are designed in accordance with international quality standards. With the assistance of experienced professionals and their dedicated efforts, we have become a leading supplier of these home containers that are offered at competitive prices. Prefabex house Containers represent a perfect building solution because they are easy/quickly constructed, strong, environmentally friendly, stackable, mobile, structural Integrity, easily Transported and Economical price. We can create any portable house of various sizes making buildings fully customized to fit your requirements. They can be ideally used as temporary living portacabin, modular apartments, modern vacation homes, residential homes and temporary and permanent accommodation. We deliver and install fully ready houses in a very fast and efficient way.

Request for a quote

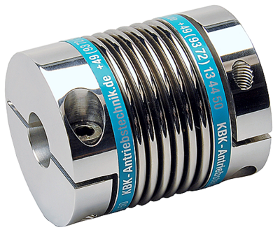

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with collet clamps / Hub material: aluminum Backlash-free metal bellows coupling with clamp hubs Hub material: aluminum Alternatively to steel executions we recommend our series KB4AL from size 80 - 500 For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy assembly and low inertia Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 500 Nm

Request for a quote

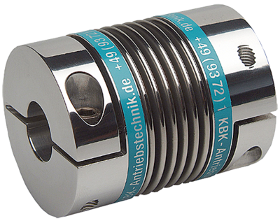

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with collet clamps, compact Backlash-free metal bellows coupling with compact clamp hubs For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with collet clamps Backlash-free metal bellows coupling with clamp hubs Hub material: up to 60Nm – aluminum, up from 80Nm - steel For shaft diameters from 10 – 80 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy to assemble Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling axial pluggable Backlash-free metal bellows coupling as axial pluggable execution Easy assembly / disassembly by simply plugging / pulling the coupling parts High tensile aluminum and special coatings ensure a durable solution at low mass / inertia For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 500 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with split hubs Backlash-free metal bellows coupling with split hubs For shaft diameters from 10 – 80 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Miniature Metal Bellows Coupling with split hubs Backlash-free miniature metal bellows coupling with split hubs For shaft diameters from 3 – 25 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines, Torque range: 0,5 – 10 Nm

Request for a quote

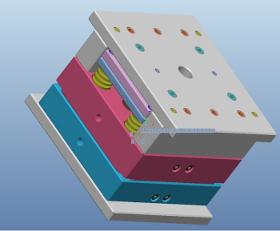

XUFENG TOOL TECH GROUP LIMITED

China

XF has 15 injection Machines on a 7 day shift system, our constant shift pattern enable us to confidently offer reduced lead times and faster deliveries to you. we export many molds each year to North America,Europe,etc mainly for small to medium molds, automotive partis,electrical parts, etc Rich molding experience in processing various materials including ABS, PP, PS, PC ,PMMA, PE,POM, PA6/66+GF,PET, PBT, TPE. 100-850 tones machine capacity Our technique staffs will do periodical checking and maintenance to ensure our machine run normally and all of our products have passed through very strict quality control before shipment.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Plastic Injection Molding Service Xufeng specilized in fabricating plastic injection moulding parts and mould tools over 10 years ,98% are for export. Here we are expert on rapid injection molding ,We offer toolings design and building at our workshop and we are used to working on low and medium volume production Runs. part material molding range widely like ABS,PP,PC,PMMA,PET,PA6/PA66,PA66+GF... Our Advantages Of Plastic Injection Molding Rich molding experience in processing various materials including ABS, PP, PS, PC ,PMMA, PE,POM, PA6/66+GF,PET, PBT, TPE. 100-850 tones machine capacity Our technique staffs will do periodical checking and maintenance to ensure our machine run normally and all of our products have passed through very strict quality control before shipment. Small quantity trial order are welcome ,we all pay attention to our job. Injection moulding parts cover auto parts ,electrical& electronic parts...

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

The aluminum lags are produced precisely for all machine types. Optimized processing techniques tailored to the material ensure that the pins are securely seated. Thanks to modern CNC technology, the needle arrangement and angle precisely meet the requirements of the application. For a high-quality replacement of the original equipment at an optimal price-performance ratio, we are looking forward to your inquiry! A questionnaire is available below, alternatively, send us a sketch. The specification of machine type and desired needle density often suffice.

Request for a quote

TURBOWORKS LTD

United Kingdom

The most effective way to clean blocked DPF/FAP/KAT filters is by using a high-pressure water jet combined with a carefully selected detergent. This method, known as hydrodynamic treatment, involves using a pressurized water machine and is the only technique that can thoroughly remove all types of particulates from both the inlet and outlet channels of the filter insert. The jet of working fluid is directed from the outlet side of the filter—usually the unblocked outlet channels—allowing the water and detergent to permeate the micropores in the walls that separate the channels and reach the clogged inlet channels.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

MAXIMUM PERFORMANCE! Compared to vibratory finishing vibrators, Trowal Turbotron centrifugal units offer up to 10 times the grinding power. grinding performance. Turbotron machines are mainly used for the removal of heavy burrs and for edge rounding edges on small and medium-sized mass-produced parts. However, by applying special process techniques, Turbotron machines can also be used for fine grinding and even polishing. even polishing. HOW IT WORKS The rotation of the turntable (60-250 rpm) accelerates the abrasive / workpiece mass and the centrifugal force on the inner wall of the stationary work bowl deflects it upwards. deflected. Due to the onset of gravity, the mass slides back onto the turntable, from where it is accelerated again from there.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCANDINAVIAN & UK MACHINES

Sweden

The E-12 is a block machine that uses a technique known as “egg laying,” where the block machine moves and produces concrete block products on the ground to dry – We offer the machine in fully/semi-automatic modes. With the SUMAB E-12, the following concrete products can be produced in an efficient way: • Hollow block stones • Solid block stones • Chimneys • Light weight blocks • Paving stones [with vibration table option] *additional option Production capacity: For hollow blocks 400 x 200 x 200 mm ………. 1.200 blocks/h. For hollow blocks 400 x 200 x 120 mm ………. 2.000 blocks/h. We offer Scandinavian quality and good price!

Request for a quote

CARONI S.P.A.

Italy

The FL series of light rotary tillers, which can be attached to small and medium-sized tractors with 15 to 40 HP, is ideal for use in orchards, vineyards and market gardens. The FM series of tough compact medium-sized rotary tillers, suitable for tractors ranging from 35 to 60 HP, is ideal for small/medium-sized farms. These are relatively light machines which, despite the fact they do not require a great deal of power, are mechanically tough as a result of the high quality materials used in their making. Designed with the most up-to-date technology to meet the requirements of ever more advanced farming techniques, these machines combine versatility and compactness with extremely easy handling, which means they are at home on any type of terrain. The 3rd floating point and the adjustable hitches are always centered on the tractor axis but allow the tiller to be moved 16 cm to the right. This important innovation has been employed on the 1100 - 1200 -1300 and 1400 versions of the FL series, and on all the FM models. The chain drive, positioned at the side of the tiller, is housed in an oil bath and has a manual tension regulator. The disk rotor has 6 hoes per disk. Side skids used to adjust the tilling depth are standard fittings. The standard universal joint can be supplied with a clutch or bolt limiting device upon request. The hitches, which are also standard fittings, allow these tillers to be used with any type of tractor. Rotary Tillers: Caroni by Kubota

Request for a quoteResults for

Machine techniques - Import exportNumber of results

20 ProductsCategory

- Measurement and control instruments (6)

- Machine tools, metal machining - parts and accessories (4)

- Adjustment - machine tools (1)

- Bending machine tools (1)

- Blow moulding of rubber and plastic (1)

- Brass (1)

- Brick-making - machinery and equipment (1)

- Buildings, modular (1)

- Custom packaging (1)

- Fuel, petrol and diesel economy systems (1)

- Injection moulding of rubber and plastic (1)

- Magnets (1)

- Plastics moulding (1)

- Textiles - Machines & Equipment (1)

- Turning - steels and metals (1)