- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine automation

Results for

Machine automation - Import export

MAROVT D.O.O.

Slovenia

The advantage of the Marovt company is that forged parts are machined in our own forge. This is why we are able to ensure forged parts with characteristics defined together. The machining of forged parts is mostly automated; therefore, the human factor is decreased and permanently the same technological process can assure all parts to be machined in the same way and being controlled and tested according to the same procedures.The machining of forged parts is carried out on technologically advanced 3 and 4-axe machines. Our machining centres have the possibility of using up to 40 changeable cutting tools. The tool can be up to 300 mm long and up to 10 kg heavy.The machining center spindle can rotate up to 20,000 rpm. Changing the cutting tool at our centers only takes 1.7 s, which greatly shortens the machining time. All our machining centers have a pallet system that eliminates the time of mounting the forging parts into the clamping device.

Request for a quote

STOBA SONDERMASCHINEN GMBH KG

Germany

stoba ECM systems with adapted automation solutions for multishift operation System comprising proven standard modules Integrated process chain of transport, ECM, cleaning, drying and removal Expansion stages based on the production volume Achieving economic cycle times Layout adapted to space Process integration and support from a single source

Request for a quote

IRIS PACK

Poland

New fully automated machines for the production of disposable plastic gloves made of HDPE / LDPE foil

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Long-term system reliability at the lowest cost Service technology Lödige Industries provides bespoke maintenance services for equipment ranging from single machines up to complete automated systems, which guarantee your assets operate reliably and at the lowest possible cost. At the same time, our international service network ensures a fast response in the event of random faults even for equipment not delivered by Lödige. As your needs change over time, Lödige can also support the expansion of your facility, or the transition to new technologies. Lödige have a strong track record for delivering system enhancements or modernisations whilst Clients continue to run their day to day business. MAINTENANCE The modular configuration of our maintenance agreements provides you with long-term reliability at the lowest cost. CONSULTING We provide expert advice on the current condition of your systems and potential for improvement with regard to technology, throughput and operation. ...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC milling is an automated machining process used to manufacture 2D and 3D parts by removing material from raw stock . This process is used in various industries such as aerospace, automotive, and industrial equipment to produce a wide range of parts, including gears, shafts, brackets, and housings .The precision and accuracy of CNC milling make it an ideal process for producing complex and high quality parts .It can produce parts of nearly any shape from soft metals like aluminum, harder metals like steel, and plastics such as acetal...

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Innovative manufacturing solutions for the production of light-duty to heavy-duty automotive components. Automotive components and engines considerably vary in size: from small 0.9L 2-cylinder through to 16L V-8 engines. To provide tailored solutions for these components, HELLER consistently focuses on manufacturing systems in modular design. In addition to the “classic” machining centres from the H, F and C series and the RFK/RFN/DRZ machines for crankshaft and camshaft machining, we are offering the following manufacturing solutions: Highlights Wide range of machine technology Model ranges in modular design From stand-alone machine through to fully automated manufacturing system Comprehensive manufacturing solutions Complemented by all services required for the operation of the machinery Advantages For flexible series production For maximum productivity For minimal piece-part costs For a significant reduction of unproductive idle times For highest availability

Request for a quote

IGUS® GMBH

Germany

E4Q energy chains have been developed to provide the best possible solution for unsupported and long travels. Based on the robust E4.1 energy chain standard, which has proven itself over 12 years, the new series brings a long service life and high modularity. - Tool-free opening and closing - Reduced protrusions in the interior, for easier filling when the e-chain® is open - 15 % more pull-out force of the opening webs compared to the E4.1 system - 10 % less weight due to material recesses compared to system E4.1 - Optional 17 dB(A) quieter due to noise-reducing parts made of material optimized for noise level - 40 % less installation time compared to system E4.1 - Up to 35 % savings possible when used in the limit range - 36 months warranty - Predictive maintenance - optional with the isense add-on module Typical applications: Machine tools, crane systems, automation systems

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This fully automatic labeling line is suitable for reliably applying self-adhesive labels to various products such as envelopes, catalogues, magazines, etc. The machine is equipped with a completely overhauled rotary feeder from CMC, which we installed as a self-sufficient unit with a new vacuum pump and motor in a stable frame made of aluminum profiles. We then paired them up with a new vacuum table with electric height adjustment and an "Alpha Compact" labeler from BLUHM/WEBER mounted on it. Together with a new machine control system these modules can be assembled into a fully automatic labeling line with which our customer can process products up to 43 cm in length at high speeds (up to 70 m/min). Our systems can be freely configured according to your needs. Tell us your requirements so that we can present a concrete solution proposal.

Request for a quote

FÖHRENBACH GMBH

Germany

The versatile control unit for handling, assembly technology, linear robots The unipos 330 is a universal, modular CNC continuous path control for up to 3 axes (interpolating) in connection with a PLC for controlling most reliable applications for machine construction automation technology, machine tools and special applications. Depending on the design, either stepper motors or servomotors are used as axis drives. The integrated panel PC with the LINUX operating system allows convenient programming of your application and the user interface (HMI). Features Interpolating continuous path control for a maximum of 3 servo axes CNC programming using G code 1 to 3 axes / stepper motors or servomotors Processor: 32-bit microcontroller, 400 MHz, without fan 7" touch screen, resolution: 800 x 480 DPI, TFT colour

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Component placement requires individual approaches. Our range of solutions covers small series produced by hand, medium-size series using semi-automated wave soldering machines and fully automated production lines for large-scale manufacture. We adjust the level of assembly automation to your project – so that you achieve the best result both economically and technically.

Request for a quote

MESSER CUTTING SYSTEMS GMBH

Germany

STATE-OF-THE-ART LASER TECHNOLOGY FOR MAXIMUM PRODUCTIVITY AND QUALITY Leap in performance in laser technology! Whether it is rapidly increasing laser powers, different fiber types or even new cutting gases: Today's laser machines must be able to follow current trends. Innovation is needed as applications must become more effective and transparent. In addition, the increasing shortage of skilled workers is pushing for plants to become more self-sufficient. One machine operator alone has to be able to supervise several machines. Automation of nozzle change material supply and removal and continuous data exchange or reconciliation across the entire production flow are the prerequisites that were at the forefront of the ELEMENT L's development.

Request for a quote

MICRO-EPSILON

Germany

Non-contact eddyNCDT 3300 eddy current displacement sensors are designed for use in factory automation, for machine monitoring, for quality control and quality assurance. More than 80 differentes sensors models are available.

Request for a quote

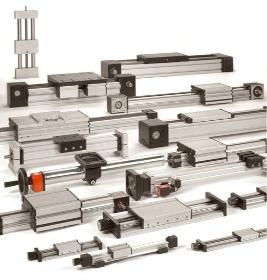

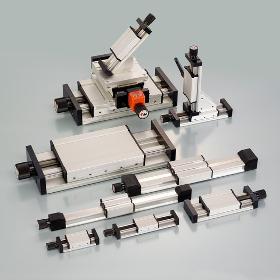

RK ROSE+KRIEGER GMBH

Germany

Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

One of the most significant advantages of an automatic piston filling machine is that it reduces labour costs and increases production speed. The machine can handle a high volume of products, which can help to reduce manufacturing costs in the long term. Furthermore, as the machine is fully automated, it minimises the risk of human error, which further increases production efficiency. Model Recommended: NP-VF 12 Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L

Request for a quote

MINEBEA INTEC GMBH

Germany

OPC UA (Open Platform Communications Unified Architecture) is a standard for communication in the field of industrial automation - more precisely: a machine-to-machine communication protocol for industrial automation. The server enables cross-operating system data exchange between, for example, scales and higher-level systems such as ERP or MES systems. miOPC is suitable, for example, for the Combics, Signum, Midrics and IS platforms. With miOPC, Minebea Intec, as an innovation leader, offers a new solution for the market that takes an important step towards standardisation and customer independence. Your benefits: — Simple connection of existing scales via Ethernet TCP/IP or serial RS232 — Standard OPC UA scale profile according to the OPC Foundation: "OPC UA Compendium Specification for Weighing — Data security through encryption — Simple, intuitive operation

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIC - KLAUS CZERWONKA

Germany

control panels, control cabinets, pneumatic systems, pneumatic systems, control units, pre-assembled pneumatic modules for machines and plants in automation technology factory automation assembly lines test benches Also for automotive applications such as brake test benches, assembly robots, conveyor belts. Design, layout, assembly, plug and play delivery. We are also happy to use components according to the parts list, specifications or customer specifications.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

MTA ROBOTICS AG

Switzerland

MRC500 soldering platform for robotic soldering from above is a free-standing machine cell. Our design engineers purposes-built the MRC500 for soldering applications then standardized the design. We purpose-built our own platform so we would not need to compromise functionality based on the limitations of third-party equipment. Standardizing the design offers three primary advantages. It is well-proven, available faster, and costs less than-off custom designs. Although the design is standard, it is highly flexible. We designed the mechanical structure to work with a wide range of process equipment, material handling, and guarding systems. In its basic configuration, the MRC500 is a free-standing, semi-automated machine. At the other extreme, we can outfit it with SMEMA conveyors, collaborative robots, turntables, and many other systems.

Request for a quote

MICRO-EPSILON

Germany

The thermoMETER TIM 8 combines the advantages of a robust pyrometer with a thermal imaging camera. Due to its extremely compact size, it can also be integrated into machines and production lines. The spotfinder function enables precise temperature measurements with automatic sensor adjustment. In addition, remote focusing of the lens is possible via a motorized focus. This intelligent spotfinder pyrometer is used in automation, machine building and plant monitoring.

Request for a quote

MICRO-EPSILON

Germany

The MSC controllers are designed to be operated with LVDT and LDR measuring gauges and displacement sensors. Due to the robust and compact aluminum housing, the controllers are ideal for industrial measurement tasks. A large variety of compatible, inductive displacement sensors and gauges combined with an optimized price/performance ratio opens up multiple fields of applications in automation technology and machine building.

Request for a quote

IRIS PACK

Poland

New fully automated machine for the production of bags,disposable plastic gloves made of HDPE / LDPE foil. Machine started, tests done. Possibility to check. Station with double unwinding, equipped with clutches for smooth adjustment of HDPE tape tension, double inverters controlling unwinding. The machine uses a central drive that controls all mechanisms responsible for forming production. The feeding of the material is controlled by a stepper motor (servo drive) enabling precise feeding of the HDPE or LDPE tape to the welding position and the final product sorting point. Possibility of changing the welding dies to different sizes of gloves or the production of bags, e.g. for breakfast. Capacity approx. 160 pieces / min Power consumption: 10 Kw Compressed air demand: 8 BAR Weight: 1300 kg

Request for a quoteResults for

Machine automation - Import exportNumber of results

161 ProductsCountries

Category

- Industrial maintenance (12)

- Construction - Machines & Equipment (9)

- Servomechanisms (9)

- Laser - cutting and welding machines (6)

- Measurement and control instruments (6)

- Storage equipment and systems (6)

- Automation - systems and equipment (4)

- Cleaning and maintenance products, household (4)

- Electrical systems and equipment (4)

- Packing and packaging - machinery and equipment (4)

- Machine tools - metal machining (3)

- Paper - Printing - Machines & Equipment (3)

- Sensors (3)

- Textiles - Machines & Equipment (3)

- Tools, pneumatic (3)

- Bags, plastic (2)

- Cutting - steels and metals (2)

- Electrical components and parts (2)

- Engines & Parts (2)

- Industrial robots (2)