- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- low-pressure moulding

Results for

Low-pressure moulding - Import export

MOH D.O.O

Slovenia

components for making tools for Rubber injection plastic injection high pressure aluminium injection moulding low pressure injection components for making cutting tools components and construction of clamping devices housings holders

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

The decisive factor for the technical implementation of every project is the appropriate casting tool. Each one is individually developed, designed and manufactured for the respective project. Our experienced designers and project managers are always available to advise you! Low Pressure Moulding Tools

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

At OptiMel, you get everything from a single source to optimally use low pressure molding technology for high-quality electronics encapsulation. Thermoplastic hot melts are used as encapsulation material. Due to their range of properties, amorphous thermoplastic polyamide granules are predominantly used in low pressure molding. Thermoplastic polyolefins are also available for special applications, which are used whenever sufficient adhesion cannot be achieved with the preferred polyamides on the substrates used (e.g. cross-linked polyethylene). Due to different raw material combinations, the range of properties of these hot melt granules varies in terms of mechanical strength, operating temperatures and resistance to various media. The hot melt molding materials combine a viscosity spectrum that is favorable for the low-pressure process with a wide operating temperature range (-50 / + 150°C) and, in some cases, very good adhesive properties. Depending on the material

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Optimel is your reliable partner for solutions for encapsulating electrical and electronic assemblies. The innovative Low Pressure Moulding (LPM) technology offers optimal protection against external influences such as moisture, dust and vibrations, thus ensuring the longevity and reliability of your products. The Low Pressure Moulding process or hotmelt moulding process originated in the sealing of cable harnesses in the automotive industry - today it is used in many areas for the protection of electrical and electronic components. At 5-40 bar (in individual cases up to max. 60 bar), processing takes place at a much lower pressure than in the classic hotmelt injection moulding process. This makes it easy to directly encapsulate even sensitive components such as circuit boards, sensors, etc. The cycle times are limited to pure encapsulation

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

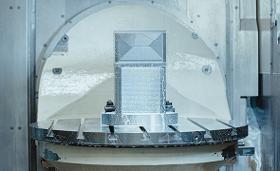

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics casting The BASEline series combines a compact design and convenient operation and can be used optimally for the majority of low pressure molding projects. Various mechanical components can be put together depending on requirements. The adapted melting device with double-acting piston pump, 4l tank volume and a melting capacity of approx. 1kg/h enables optimal processing of small to medium shot weights and/or quantities. The available clamping force of 9/12kN is suitable for casting surfaces up to approx. 3,000mm². By using the Siemens S7-1200 control with touch panel, the series offers the same ease of use as the larger series.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics encapsulation The FLEXline series offers maximum flexibility through the modular design of various variants as well as expanded options for implementing special functions. The adaptation or addition of individual mechanical components is just as possible as special programming or integration into a complete production line. In addition, various application systems are available, including hot runner systems with different nozzle geometries and arrangements. The melting units can be optimally tailored to the requirements of the respective project with different melting and conveying systems and, if project requirements differ or change, can be replaced at any time using our "plug-and-play" system. Extensive peripherals and additional options round off the system. The FLEXline can therefore be optimally tailored to the requirements of the respective project.

Request for a quote

ELANG INDUSTRIAL (SHANGHAI) CO., LTD.

Spain

Low pressure screw air compressor series is a new compressor produced according to the national policy of energy saving,emission reduction and environment protection.It changes the traditional compressor with relatively high pressure.It transfers the compressed air after pressure reduction to the air consumer,which waste large amounts of energy. The low pressure screw air compressor can be distributed according to the air pressure of the user,to satisfy the process flow with minimum energy.The manufacturing cost of your product can be largely improved.For example,if your process system only needs 3 bar pressure and the used compressor can provide 7 bar, then it can be reduced to 3 bar, It may take two times power to satisfy you process system, you can choose our low pressure screw compressor only to consume half of the power,and the air pressure in the process system can still be ensured, thus realizing energy saving and emission reduction.

Request for a quoteResults for

Low-pressure moulding - Import exportNumber of results

8 ProductsCountries

Company type