- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- long holes

Results for

Long holes - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel Long version with three cutting holes, Ensat 308 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Similar to Ensat 307 but longer, so can be applied in thicker materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material

Request for a quote

MICRON AMERICA

Turkey

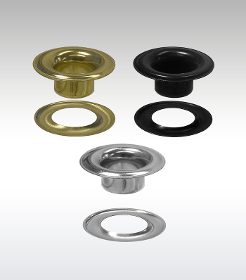

Brass grommet and teeth washer provide rugged and unyielding setting for a wide variety of applications. Manual, semi automatic and fully automatic grommet setting machines easily set grommets and plain washers ensuring installation runs smoothly and efficiently. This multipurpose grommet and washer combination can be used in a variety of materials including industrial fabrics, canvas, leather and heavy duty vinyl tarps, as long as a hole has been pre punched in the material. Please take a look to the chart in order to find the dimensions you need for every size and finishes of sheet metal grommet and teeth washer manufactured by Micron America.

Request for a quote

MICRON AMERICA

Turkey

Brass grommet and plain washer provide basic hole reinforcement and versatility for a wide variety of applications. Manual and semi automatic grommet setting machines easily set grommets and plain washers ensuring installation runs smoothly and efficiently. This multipurpose grommet and washer combination can be used in a variety of materials including industrial fabrics, canvas, leather and heavy duty vinyl tarps, as long as a hole has been pre punched in the material. Please take a look to the chart in order to find the dimensions you need for every size and finishes of sheet metal grommet and plain washer manufactured by Micron America.

Request for a quote

MICRON AMERICA

Turkey

Rolled Rim Grommets with Spur Washers are available in brass with a selection of finishes including nickel plated and brass and military black.Specifically engineered to interlock, the teeth of the washer grab the material ensuring a rugged and rigid setting. This multipurpose grommet and washer combination can be used in a variety of materials including industrial fabrics, marine canvas, boat covers, awnings, and heavy duty vinyl tarps as long as a hole has been pre punched in the material. Please take a look to the chart in order to find the dimensions you need for every size and finishes of rolled rim grommet and spur washer manufactured by Micron America.

Request for a quote

MICRON AMERICA

Turkey

Rolled Rim Grommets with Spur Washers are available in brass with a selection of finishes including nickel plated and brass and military black.Specifically engineered to interlock, the teeth of the washer grab the material ensuring a rugged and rigid setting. This multipurpose grommet and washer combination can be used in a variety of materials including industrial fabrics, marine canvas, boat covers, awnings, and heavy duty vinyl tarps as long as a hole has been pre punched in the material. Please take a look to the chart in order to find the dimensions you need for every size and finishes of rolled rim grommet and spur washer manufactured by Micron America.

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • Ideal for perforated brick (Poroton) and cellular concrete (Ytong) • Extremely high holding values • Spreads in several directions • Rotors prevent rotation in the drill hole • 100% nylon • Long expansion range for secure anchoring • Also suitable for metric threaded rods Description & Area of Application • Multiple expansion by 2-way separated expansion elements which are offset by 90° with moving rotors and flexible wall plug neck • Large anchoring depth

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S19, S20 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S19, S20 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The S19, S20 inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance They induce very low radial stresses and are therefore particularly recommended in holes with thin walls. In this case the hole must be a bit wider. Optimal size should be determined after appropriate practical tests Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S14 (Long version) are inserts for plastic with heat/ultrasonic installation into tapered holes with an 8° angle These are the longer versions of the S14 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The tapered form facilitates proper seating and maximizes the surface contact between the insert and hole wall prior to the application of heat or ultrasonic vibration. These inserts are the best choice when using ultrasonic insertion techniques The insert's straight-toothed upper ring and oblique-toothed middle ring provide high torque and pull out resistance, ensuring complete filling of the plastic material in the cavities below Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Inch version from 2-56 to 5/16-18 is available upon request

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance Long version with three cutting holes, Ensat 308 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Similar to Ensat 307 but longer, so can be applied in thicker materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

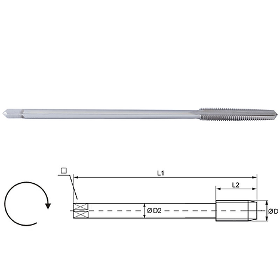

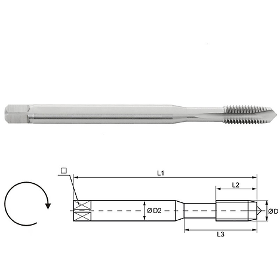

Thread standard: Metric, ISO DIN 13 Type: Machine nut tap Application: General use Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 850 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Maschine Nut tap for through holes with long shank for taking some thread cutted nuts. For thread depth up to 1,0 times diameter. Also useable for thread cutting in awkward places. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

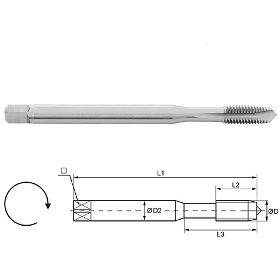

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Overlengthed (long shank) L=150 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Overlengthed (long shank), L=150 Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

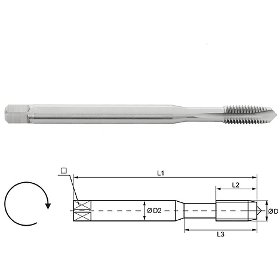

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Overlengthed (long shank) L=120 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Overlengthed (long shank), L=120 Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Overlengthed (long shank) L=100 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Overlengthed (long shank), L=100 Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For cutting hard and soft wires • For holding, gripping, bending and cutting work • Cutting edges inductively hardened • With cutting edge and burner hole • With long, 45°-angled, flat-round jaws • Serrated inside jaws • Integrated ring spanner • Handles with ergonomically shaped SoftGripp multi-component safety sleeves according to DIN EN/IEC 60900 • SoftGripp handles with SystemSocket for holding optionally available accessories, e.g. the easily attached SystemClip for fall protection • Made of tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For cutting hard and soft wires • For holding, gripping, bending and cutting work • Cutting edges inductively hardened • With cutting edge and burner hole • With long, 45°-angled, flat-round jaws • Serrated inside jaws • Integrated ring spanner • Handles with ergonomically shaped SoftGripp multi-component sleeves • SoftGripp handles with SystemSocket for holding optionally available accessories, e.g. the easily attached SystemClip for fall protection • Made of tool steel, forged, oil-hardened

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The universal reamer for all types of holes, particularly for in-line reaming of two or more holes and for reaming very long holes. Description Right-hand cutting reamer with expanding blades. Interchangeable pilots with guide sleeves at the front as well as at the back of the reamer. The guide sleeves provide for exact alignment between the hole being reamed and the other mating holes. A special bayonet coupling with mating cones between each pilot and the reamer body ensures correct alignment. Due to the unique Hunger relief grinding operation the blades have a progressively increasing clearance angle giving a soft cutting action. The adjusting nut is marked with a annular scale. One graduation of the scale corresponds to a change of the reaming diameter by 0,02 mm. The reamers are available with standard blades made of high quality special steel to ensure superior cutting performance. The reamers are also available with hard chromium coated blades.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASSFALG GMBH

Germany

The SMA 30-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 8 mm is possible in NE metals and a chamfer width of up to 6mm in steel. In addition to this, a radius processing of 1.2mm to 6mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The electrical design of the SMA 30 is equipped with a speed control and should be preferably used for stainless steel processing. The cutter heads are available for chamfer angles 30°, 45° and 60°. The processing of drill holes is already possible starting at a diameter of >28mm. For tight contours, long holes and bores, a single-cutting cutter head with a fitting guide roller is available, Ø10mm to Ø20mm depending on application.

Request for a quoteResults for

Long holes - Import exportNumber of results

19 ProductsCountries

Company type