- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- liquid mixtures

Results for

Liquid mixtures - Import export

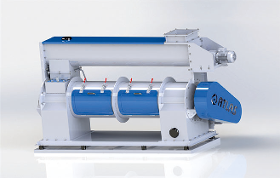

PARSMEGA MAKINA

Turkey

It ensures the production of the product with the desired properties by providing the appropriate additive for the appropriate feed. It provides continuous and homogeneous mixture with the liquid spray system and can be easily cleaned thanks to its wide covers.

Request for a quote

ROBINSON CO.

Turkey

The mixer is designed to homogenize the mixing of different raw materials milled to the mill with poor free flow during the process. Both types of mixing are possible with or without the addition of liquid. it provides a mixture of raw materials crushed with a precision of 1/100000. The loading time is reduced by pneumatic traps in a large area; and the unloading time is reduced by double unloading hatches that can be opened from end to end.The position/time increases with the time gained during the finishing process.There are 100% safe unloading housings that do not load Rotating equipment should never be opened unless the cycle is completed. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROXSTONE HOLDING B.V.

Netherlands

Name: Vaseline; Vaseline. Petroleum jelly. Mineral butter; Vaseline. Properties: A semi-liquid mixture of alkanes or saturated hydrocarbons, also called petrolium, obtained by fractionation of petroleum. Application: When applied to the skin, it can keep the skin moist, keep the skin tissue in the best condition at the wound site, and accelerate the skin's own repair ability. Solubility: Soluble in ethylll etherrr, chloroform, gasoline and benzene and other organic solvents. Insoluble in water. Good chemical stability and oxidation resistance, with good oxidation stability, stability and light stability. It is suitable for making hair cream, hair oil, hair wax, lipstick, face oil, skin cream, etc. Also used for light machinery and precision instrument lubrication, cosmetics, food industry and textile industry mechanical lubrication. 1.Name: Vaseline 2CAS No:8009-03-8 3.Purity:99%min 4.Appearance:8009-03-8 5.Assay:HPLC 99%

Request for a quote

SCHREIBER ESSENZEN GMBH & CO. KG

Germany

Spice mixed according to specifications of customers. 8 Standard mixtures available Liquid spices (for soups sauces and salads)

Request for a quote

FLOTTWEG SE

Germany

Disc stack centrifuges are high-speed centrifuges for the mechanical separation and clarification of mixtures comprising solids and liquids. Due to their special design, disc stack centrifuges work at a very high rotation speed. As a result, the centrifugal acceleration (g-force) generated by a disc stack centrifuge is extremely powerful. Moreover, the discs included provide a large clarifying area. Thus, it is possible to separate ultrafine solid particles from a liquid and to separate liquid mixtures in an efficient way.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® Explosionproof screw plug or flanged immersion heaters ( Ex ) are perfectly suited for direct heating of liquids or gas / air mixtures in hazardous areas. The devices are available with attached or integrated temperature monitoring systems. For these heaters various high quality stainless steel grades are available. The electical immersion heater type 94./..EEs….T.(.) is designed for the heating of liquids and quit gasair mixtures in the zone 1 and zone 2. The standars elements, mentioned in this list are suitable for DGRL (code 97/23/EG) Art. 3 Para. 3. The elements can be suited (on request) to other uses requiring another classification according to DGRL.

Request for a quote

LUTZ PUMPEN GMBH

Germany

For liquids that have to be mixed before processing and then pumped or contain small solids, the new Diaphragm pumps with an integrated air-operated Double diaphragm pump is the perfect solution. The mixing and pumping process takes place via a suction and mixing tube and a 3-way valve. The pre-assembled system is immediately ready for operation with a few simple steps and is also suitable for explosive liquids. * Mixing and pumping integrated in one system * stufenlose Regelung der Folgeplatte über Steuerventil * Media examples: Paints and varnishes, emulsions, dispersions, suspensions, water/oil mixtures, liquids with increased viscosity and solids content Features & Advantages * Quick installation and time saving through easy handling * Compact design * Base plate offers good stability on the container lid * Easy to insert into the 2" bunghole of the container by balancer or overhead crane * No further mixer necessary

Request for a quote

FLOTTWEG SE

Germany

In many aspects of process engineering, separators are used for mechanical separation and clarification of mixtures comprising solids and liquids. A separator is liquid-oriented and works with a higher rotation speed than a decanter. As a result, the generated centrifugal acceleration (g number) of a separator is significantly more powerful than in decanter centrifuges. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). Furthermore, Flottweg separators are suitable for separating mixtures of liquids with different densities at the same time as separating a solid (purifier). Flottweg AC separators (Automatic Cleaning) can be used in a wide range of applications, and are also available in various configurations. — Beverage and brewing industry — Starch industry — Chemicals and biotechnology — Extracting and processing fats and oils

Request for a quote

IFA TECHNOLOGY GMBH

Germany

In order to meet your requirements when mixing liquid and solid substances, our plants and systems enable the mixing of combinations in virtually any state of aggregation. IFA Technology is your competent partner for the right process - no matter if you want to mix liquids with liquids, solids with solids or liquids with solids or gases. We develop a wide range of applications for the production of the respective product - whether homogeneous or heterogeneous mixtures, suspensions, temporary liquid-liquid dispersions, emulsions using lipophilic and hydrophilic liquids or the mixing of bulk materials such as powders, granulates or flakes.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Despite the increasing level of digitalization, an ever-increasing demand for paper and pulp products can be observed. However, a shift is taking place from print paper qualities to packaging paper and cardboard. The wide range of paper products requires a variety of production processes. These include mechanical and chemical processes which, depending on the form and variant, produce different pulp qualities. Stirring and mixing are essential unit processes in all types of paper and pulp production. Mixing tasks range from liquid/liquid or gas/solid/liquid mixtures, through mixing of complex liquids, and include mixing of chemically reactive components. Improving and optimizing mixing processes in the paper and pulp industry can lead to end product improvements; such as increased strength, improved luster, or significant energy or chemical savings.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Deep Cone Thickener Tank is a plant process equipment used in separating and concentrating solid-liquid mixtures in mineral processing plants, wastewater treatment facilities, and other industrial processes. This tank features a cone-shaped bottom that allows efficient sedimentation and thickening of fine particles and slurry. During entry of the mixed slurry into the tank, the solids settle to the bottom due to gravity and form a dense cake; the clarified liquid overflows from the top. The deep cone design of the tank provides an increased settlement area and steep slope angle, facilitating the separation and thus assuring maximum concentration of solids in the underflow. The Deep Cone Thickener Tanks find wide application in processes where thickening, dewatering, or separation of solid-liquid is required with high efficiency in attaining the desired levels of concentration and clarity of liquids.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Deep Cone Thickener Tank is a plant process equipment used in separating and concentrating solid-liquid mixtures in mineral processing plants, wastewater treatment facilities, and other industrial processes. This tank features a cone-shaped bottom that allows efficient sedimentation and thickening of fine particles and slurry. During entry of the mixed slurry into the tank, the solids settle to the bottom due to gravity and form a dense cake; the clarified liquid overflows from the top. The deep cone design of the tank provides an increased settlement area and steep slope angle, facilitating the separation and thus assuring maximum concentration of solids in the underflow. The Deep Cone Thickener Tanks find wide application in processes where thickening, dewatering, or separation of solid-liquid is required with high efficiency in attaining the desired levels of concentration and clarity of liquids.

Request for a quote

PHARMAHEMP D.O.O.

Slovenia

PharmaHemp® hemp terpenes represent an essential oil produced by steam distillation, which gives a unique hemp aroma and flavour. Hemp terpenes are perfect ingredients of e-liquid mixtures and cosmetics.

Request for a quote

ROTORSTECH

Slovakia

Plants of these types are intended: - for the separation of liquid mixtures, which consist of two liquids, with the simultaneous removal of solid particles contained in liquids - to remove solid particles from a liquid (clarification) - for purification of mineral oils having a viscosity at a temperature of 50°C not more than 65 mm2/s - for use in power plants, substations, other energy facilities and at enterprises involved in the regeneration of technical oils

Request for a quote

MATCO

Belgium

Matco disposes of mixing vessels to produce various types of blends. Our specialty: - Liquid/liquid mixture - Liquid/solid substance mixture - Available in bulk, IBC and containers Common solutions of powders and complex compositions: the Matco team always wants to find the best solution for its customers. Together with the customer, Matco looks into specific assignments. Investments can also be discussed.

Request for a quote

VILLINA LLC

Russia

Vertical semi-submersible pumps are designed to solve the problem of pumping liquid out of a tank when a part of the pump is within the pumped medium. Pump units are used with the engine speed up to 3,000 rpm. Therefore, the temperature conditions for semi-submersible pumping units are up to 250 degrees. Centrifugal semi-submersible pumps are widely used both in petroleum refining (petroleum and drainage pumps) and the chemical industry, and in the food industry. They are used for transit of various liquids and mixtures including explosive and flammable fluids (oil and gas products, etc.). Semi-submersible pumps are in between surface and submersible units and combine all their advantages, nevertheless, a semi-submersible pump is not designed to carry out specialized tasks for which these two types of units were created. Semi-submersible pumps consist of an electric motor, a working section and immersed sections. The engine is placed on a base plate

Request for a quote

LASPARSAN COMPANY

Turkey

"The LPS-HKM-200 is a high-powered and efficient mixer used in the preparation of mortar with materials such as sand, refractory, and cement-like building materials. This machine, utilized for spraying refractory mortar, preparing ready plaster, and similar special concrete mixtures, is equipped with high safety measures, ensuring maximum operational and operator safety. It is designed to work with highly abrasive materials like sand and refractory, featuring a mixing drum and mixing blades of high hardness. Thanks to its asymmetric mixing blades, there are no unmixed portions within the drum. It is suitable for preparing entirely dry mixtures as well as mixtures containing liquid components."

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BALANCED NUTRITION S.R.O.

Czech Rep.

We also offer a "liquid program" production of hydrated mixtures, oils and gels in liquid form, so-called "shots". The main benefits of products in liquid form are absorbability, digestibility and excellent utilization by the body. We offer a wide range of top quality ingredients (stimulants, adaptogens, vitamins, minerals...), which we prepare for you in practical bottles in a variety of flavours. The possible high concentration of active ingredients will ensure an immediate/quick and noticeable effect that your customers will love and seek out again and again. Will we be preparing something to stimulate, concentrate or, conversely, calm down?

Request for a quoteResults for

Liquid mixtures - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Import-export - mechanical engineering (2)

- Pumps (2)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Concrete preparing - machinery and equipment (1)

- Cosmetics (1)

- Flour milling - machinery and equipment (1)

- Foods, health (1)

- Goods handling systems, continuous (1)

- Herbs for medicines and cosmetics (1)

- Induction heating systems (1)

- Industrial washing facilities (1)

- Livestock and poultry - feed (1)

- Mixers (1)

- Oils - recovery and recycling (1)

- Oils, cooking - machinery and equipment (1)

- Spices (1)