- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linear axes

Results for

Linear axes - Import export

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

LINEAR GUIDEWAY AND BLOCKS

Request for a quote

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

LINEAR MOTION SYSTEMS Technical Features Body : 60x80 Aluminium Profile Max. Speed : 5 meter / second Movement Distance Per Tour : 200 mm Driven : Timing Belt Timing Belt : 5M - 30 with Steel Wire and NFT Fabric Timing Pulley : Z40 - 5M - 30F Belt Tensile Force : 2000 N Timing Belt Pitch : 5 mm Shaft : Ø10 Induction Chrome Plated Bearing : RV201 - 12 KDD / LFR 5201 - 10 KDD Accuracy : 0,2 mm

Request for a quote

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

BALL SCREW MODULE Technical Features Body : Aluminium Profile Max. Speed : 0,09 meter / second Driven : Ball Screw Ball Screw : 12x05 Pitch Ball Screw Nut : 12x05 Flanged Shaft : Ø12 Induction Chrome Plated Bearing : Ø12 UU OP Bearing Open Type Accuracy : 0,2 mm

Request for a quote

GETOTEC

Germany

precision slides with ball screws or trapezoidal screw drive. - Three sizes – 100, 155 and 225 - Cover variants – sheet or bellows cover - Traversing carriage available in two lengths - Various stepper and servo motors, controllers, special versions such as - Motor deflections via timing belt drive make the precision slides universal can be used and are optionally available with or without motor. - Integrated limit switches (inductive proximity switches) with cable entry or plug connection in the endplate. - Base plate and end plates are made of a surface-treated and high-strength aluminium alloy. - Modular use, e. g. as multi-axis systems

Request for a quote

POR METAL URUNLERI INSAAT TURIZM VE SANAYI TICARET LIMITED SIRKETI

Turkey

It is a type of door in which the door leaf, which is connected by consoles between bearing groups placed on vertical and horizontal axes, performs a linear opening. The absence of a rail on the floor provides a problem-free working environment for forklifts and similar vehicle entries. It has the appropriate infrastructure for the installation of electronic lock systems.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. Horizontally mounted, it is mainly used to feed presses installed in series. It extends in both directions, feeding a press in one direction, closing, then feeding another in the other direction. The closed actuator does not occupy space in the two presses, making it possible to feed both with a single system. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg with fast and silent functioning. Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements. Our products stand out for their: easy and quick assembly; high quality and competitive performances; reduced and simplified maintenance; wide range of integrated solutions; possibility of customised solutions; constant technical support and CAD drawings available. Strong points include: hardened sloping tooth racks (ground on request); payloads from 10 to 2000 Kg; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; precise machining of all profiles (on request: repeatability up to +/-0.05mm); hardened and ground steel guide rails, for rollers and ball slides with cage; easy installation of pre-assembled systems...

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

ROLLON GMBH

Germany

Uniline System is a family of pre-assembled linear units boasting a compact size and high speed ensured by the COMPACT RAIL roller bearings, mounted on a self-sustaining extruded aluminum profile. The linear units are driven by a steel reinforced polyurethane belt system. The horizontal seals and the raceway cleaners fitted on both ends of the carriage ensure full protection from dirt. The linear actuator profile is compatible with an endless number of widely available standard fixing accessories. The motor can be connected to the units by means of a full or a hollow shaft Up to 3,000mm strokes Sizes from 40 x 51.5mm up to 100 x 122.5mm Versions available with long sliders and multiple sliders Using linear rails from the COMPACT RAIL family ensures excellent performance in terms of speed and life. The rails in the linear axes of the four product series are laid out in different combinations to meet all application requirements. Using long or multiple sliders increases the...

Request for a quote

IGUS® GMBH

Germany

This little motor has impressive torque and high RPMs. Reliable operation with quick movements of low loads. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, their precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. Motors with stranded wires are the least expensive and the most common stepper motors. The connecting wires for this type exit from the housing and will be connected with a JST connector. They are usually installed in machines and equipment that have an additional housing or are used in clean environments.

Request for a quote

IGUS® GMBH

Germany

When combined with the appropriate gearbox, drylin® linear axes with the new BLDC motors achieve higher speed and greater torque. Energy is used more efficiently, as a result of which EC/BLDC motors are more durable and have a longer service life. Due to the fact that carbon brushes are not used, brushless motors are almost completely wear-resistant, generate less heat and enable longer, uninterrupted operation. The EC/BLDC motors have the same connections as NEMA 17/23/24/34 stepper motors. - Brushless motors enable higher speed and greater torque - Longer operating time and service life - Virtually wear-free - Less heat generated - for all drylin® linear modules and axes with NEMA17/23/24/34 hole pattern

Request for a quote

IGUS® GMBH

Germany

Versatile choice due to the high torque and speed. This motor is the best choice for most applications with medium loads. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, their precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. The connector interface provides a high IP65 protection level (IP: International Protection). The higher the IP rating, the better the motor is protected from the ingress of dirt and water. The encoder sends signals from the motor to the motor control. The encoder verifies that the required linear motion has occurred precisely as required. Encoder = increased machine accuracy.

Request for a quote

IGUS® GMBH

Germany

For designs that require a stepper motor with directly integrated lead screw, drylin® E offers the ideal solution. The stand-alone versions with NEMA11 stepper motor (very small type) are available in a compact type with or without encoder. The lead screw is centred and in combination with the dryspin® high helix thread technology, the system has a long service life. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. The encoder sends signals from the motor to the motor control. The encoder verifies that the required linear motion has occurred precisely as required. Encoder = increased machine accuracy.

Request for a quote

HOCHRAINER GMBH

Germany

Hochrainer - Handling and gantry systems

Request for a quote

HOCHRAINER GMBH

Germany

Hochrainer - Handling and gantry systems

Request for a quote

TRAPO GMBH

Germany

Our high-capacity portal palletizers act in a material-caring manner on three servo-linear axes within cubic space. We develop, design and manufacture portal robots in our in-house production facility in Gescher-Hochmoor. We are a specialist in the high-care segment -with portal robots made of high-grade steel.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Sealing and bearing of rods, shafts, axes and spindles. Linear, oscillating and helical motion. Liquids, pastes and gases.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

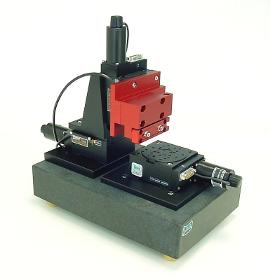

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

2 linear axes rotary stage eroded custom mounting device

Request for a quote

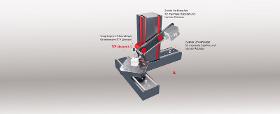

SAMAG MACHINE TOOLS GMBH

Germany

STABILITY AND HIGHEST PRECISION COME BY APPROXIMATE. THE PERFECTLY THOUGHTFUL AXIS CONCEPT IN THE POWER TOWER DESIGN ALLOWS MINIMAL TCP DISTANCE AND MAXIMUM MACHINE STIFFNESS. The POWER TOWER DESIGN impresses with its compact design and extreme rigidity. All components in the force flow are statically and dynamically optimized down to the last detail, thus ensuring perfect work results. The clear separation of all linear axes guarantees long-term dimensional accuracy of all axis drives and sustainably prevents tolerances from overlapping and thereby increasing. Thanks to the large footprint of the Y-tower and the unique DOUBLE BALL SCREW DRIVE, we always achieve optimal support for the drill beam in the TFZ and at the same time an extremely short distance between the swivel bearing and the tool center point (TCP distance), for maximum rigidity with large transverse forces.

Request for a quote

PROGRES CNC

Poland

Coordinate Measuring Machine. Precise, dynamic and reliable. The LH is a universal and flexible instrument for different applications. The revolutionary design of the new LH offers high mechanical accuracy, perfect ergonomics and dynamics. The new generation of LH is equipped with an incremental measuring system, which has a fine grating period, and excellent dirt immunity. As a result best position resolution and stability at high speed for all linear axes are possible.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The RSA Series is designed to identify suspension springs with the appropriate load class based on an individual payload measurement result. The system receives the measurement results from the upstream system. The system is available as a single or double cycle version (depending on the required throughput). Simple linear axes, single- or twin-robot systems are used as handling systems. Since the labels are normally wider than the distance between the threads, the label is preformed (Ushape) before application to reach the labelling position before it is placed around the wire and finally fixed as a flag label. The data is inspected by a vision system and compared with the original measurement information at the outfeed of the system (verification). The labels are printed in the system with various data such as customer information, barcodes and line information. The data for this is made available via the main control of the production line.

Request for a quote

STARRAG GMBH

Germany

How can large, heavyduty and bulky workpieces be processed without adversely affecting the weight and size of the machining result? The Droop+Rein G/GF series has been specifically developed to tackle this difficult task. The gantry machines reliably prevent dynamic losses through the table and workpiece. The G/GF series has many technical highlights to meet the requirements of complex machining tasks, such as the hydrostatic guide in all linear axes or the thermosymmetrical design of the spool milling unit with an integrated Caxis. Milling heads can be changed automatically via a head change interface. Droop+Rein has developed over 300 different milling heads for a variety of applications such as machining large diesel engines. The option to set up in a second working area during the machining time allows increased productivity.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The ecoLine linear model surface and profile grinding machines are comprised of a single steel base design. The longitudinal linear motor drive table with a max. speed of 60 m/min is its defining characteristic. Since 1999 hundreds of these travelling table machines have been delivered and are well established in the market. The ecoLine model is available with a grinding area of 1,000 / 1,500 / 2,000 x 700 mm. The machine is equipped with linear guides in all three axes. The Y- and Z-axes are driven by servo motors and ball screws (KGT) while the longitudinal X-axis table is powered via direct drive linear motor. The standard 11 kW grinding spindle can be upgraded up to 26 kW. A wide variety of available options like different types of dressing units provide customization capabilities for specific requirements.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The mono-base design of the multiLine models allows grinding widths (Z-axis) of up to 900 mm. The compact, steel base designed multiLine model is equipped with linear guides in all three axes. The feed axes Y and Z are driven via servo motors and ball screws. For machines up to 2,000 mm the table is driven via ball screw (KGT). For longer tables up to 6,000 mm a linear motor (LIM) is used. The standard version of the multiLine comes with high-precision linear scales for positioning of the vertical axis. The direct drive grinding spindle with up to 37 kW guarantees optimal torque transfer. To meet your requirements this model can easily be customized through a large variety of available options like different types of overhead and table mounted dressing units for using Al-oxide or CBN/diamond grinding wheels.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The powerLine technology machines are specifically geared towards creep-feed grinding applications. Their mono-base design allows grinding widths (Z-axis) of up to 700 mm with a maximum spindle power of 105 kW. The compact, steel base designed powerLine model is equipped with linear guides in all three axes. All three axes (X, Y, Z) are driven by servo motors via ball screws (KGT). The standard version of the multiLine comes with high-precision linear scales for positioning of the vertical axis. The direct drive of the grinding spindle from 48 kW guarantees optimal torque transfer. Different measuring devices and CD (continuous dressing) units are examples of a wide variety of available options making it easy to customize the powerLine to your individual requirements.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

Our gantryLine models can process large, wide and heavy workpieces up to lengths of 5000 mm and widths up to 2000 mm with high precision. Special designs are also available to process wider and longer workpieces. This machine line with its variety of available features is suitable for surface grinding applications all the way through complex CNC manufacturing cells. Next to the horizontal grinding spindle a vertical tiltspindle can be mounted for grinding for example machines beds with under grip. The sturdy gantry-style machine design features a modern vibration-free mechanical table drive, linear guideways in all axes, an over-sized spindle drive as well as ball screws and linear scales in vertical and cross axes. These features guarantee that today’s expectations in the precision machining of large surfaces are met for rough machining and high precision machining as well. The gantryLine achieves highest workpiece precision and surface quality.

Request for a quote

COHERENT, INC. - DEUTSCHLAND GMBH

Germany

The Select laser class 1 welding system offers maximum flexibility for complex welding tasks with 3 different operating modes (manual, semiautomatic and CNC), large working chamber space for bulky/heavy components and servo motorcontrolled linear axes. The system is easily controlled via a multifunctional joystick and/or a touchscreen display, which allows all inputs and parameters to be intuitively entered, managed and saved for recurring tasks.

Request for a quoteResults for

Linear axes - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Adjustment - machine tools (4)

- Electric motors and parts (4)

- Internal transport systems (3)

- Plasma cutting machines (3)

- Milling - steels and metals (2)

- Fences and gates (1)

- Goods handling systems, continuous (1)

- Industrial robots (1)

- Labelling machines (1)

- Laser - cutting and welding machines (1)

- Machine tools, metal machining - parts and accessories (1)

- Machine vision system (1)

- Measurement - Equipment & Instruments (1)

- Mechanical engineering - custom work (1)

- Precision measuring instruments (1)

- Sealing rings (1)

- Sensors (1)