- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- light alloy

Results for

Light alloy - Import export

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Machined Type Needle Roller Bearings are bearings with a low cross sectional height and large load ratings. The outer ring has stable, high rigidity and can be used even for light alloy housings. These bearings are available in metric series and inch series, both of which include a caged type and full complement type. They are suitable for a wide range of conditions including heavy load with either highspeed or lowspeed rotation. In addition, bearings are available with or without an inner ring. The type without an inner ring uses a shaft as the raceway surface, making the design compact.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Large Quantities: produced as cold formed parts (so-called multi-station presses), which require high output volumes in order to achieve a reasonable price parts Small Quantities: Produced as turned parts - the economic adjustment to small batch sizes Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry, sheet metal processing industry, telecommunications, tank- and container construction.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

With our delivery program “Screws for direct screwing” we deliver a great variety of thread rolling screws in different implementations. In doing so we realize small lot sizes and short-term delivery dates. Upon request we also introduce customer-oriented warehousing also in your company. Apart from the many advantages you can save time and money. We provide: KTG screws for thermoplastic materials: single pass thread or double pass thread (high/low); head shapes with cross or 6-star (similar Torx). Tapping screws: longitudinal slot, cross slot, cross-head-combination slot or 6-star (similar Torx). DIN 7981, 7982, 7983 or to the new ISO standards; special tip-styles, e.g. with with pressed washer. Combination screws with undetachably washers: According to DIN 6901. Self-tapping screws: According to DIN 7500. Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry...

Request for a quote

PRESSTA EISELE GMBH

Germany

5 axis CNC floor type vertical spindle machining center. 5 axis (X, Y, Z, C, A) managed by CNC. Suitable for milling, drilling, tapping and cutting on the 5 sides of aluminum, PVC, steel and light alloys profiles; thanks to the 5 axis interpolation, the machine is able to execute composite cuts. The X or longitudinal axis, the Y or transversal axis and the Z or vertical axis belong to the tool movement. They can be interpolated in linear and circular way on 3-dimension geometrical planes, belonging to X-Y-Z. The C axis can be turned and positioned on all angles within 440° (± 220°); the A axis can be tilted and positioned on all angles within 250° (± 125°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. By using the disc cutter it is possible to carry out end-milling operations on both the ends of the work piece (end-milling cycle). Milling operations can be...

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

KIGEMA SP. Z.O.O

Poland

Brass - is widely used in technology and, after light alloys, they are the most common alloys of the non-ferrous metal group.

Request for a quote

KIGEMA SP. Z.O.O

Poland

Brass - are widely used in technology and, after light alloys, they are the most common alloys of the non-ferrous metal group.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Keensert high-strength threaded inserts enter in pre-threaded holes and are secured via their locking keys. In High duty series they have 2 or 4 locking keys (depending from diameter) which once positioned make the insert mechanically locked against unscrewing from rotation or vibrations. Keenserts are extremely robust, have high resistance to rotation and extraction, a very precise thread and are easy to install and remove. They are widely used in sectors such as mechanics or precision engineering, aeronautics and aerospace on light alloys, steel or cast iron. They can also be used in damaged threads in expensive components. The Keensert inserts are supplied with the locking keys already positioned inside the grooves. The pre-positioned keys ensure that by screwing the insert it automatically positions itself at the correct installation depth. Keenserts are installed using special Keenest installation tool.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Keensert high-strength threaded inserts enter in pre-threaded holes and are secured via their locking keys. In Light duty series they have 2 or 4 locking keys(depending from diameter) which once positioned make the insert mechanically locked against unscrewing from rotation or vibrations. Keenserts are extremely robust, have high resistance to rotation and extraction, a very precise thread and are easy to install and remove. They are widely used in sectors such as mechanics or precision engineering, aeronautics and aerospace on light alloys, steel or cast iron. They can also be used in damaged threads in expensive components. The Keensert inserts are supplied with the locking keys already positioned inside the grooves. The pre-positioned keys ensure that by screwing the insert it automatically positions itself at the correct installation depth. Keenserts are installed using special Keenest installation tool. As standard, Keenserts in LIGHT duty series are supplied in:

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Keensert high-strength threaded inserts enter in pre-threaded holes and are secured via their locking keys. In Micro series they have 2 locking keys which once positioned make the insert mechanically locked against unscrewing from rotation or vibrations. Keenserts are extremely robust, have high resistance to rotation and extraction, a very precise thread and are easy to install and remove. They are widely used in sectors such as mechanics or precision engineering, aeronautics and aerospace on light alloys, steel or cast iron. They can also be used in damaged threads in expensive components. The Keensert inserts are supplied with the locking keys already positioned inside the grooves. The pre-positioned keys ensure that by screwing the insert it automatically positions itself at the correct installation depth. Keenserts are installed using special Keenest installation tool. As standard, Keenserts in MICRO series are

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

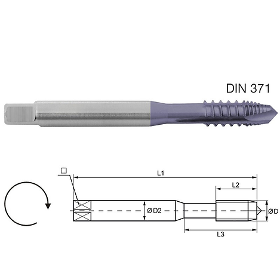

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For aluminium Material of product: HSSE Surface treatment: TiAlN For materials: Pure Aluminium, Aluminium cast and wrought alloys, Soft iron etc* Tensile strength up to: 700 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for light alloys (Aluminium, Copper, etc). The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Soft Iron Pure Aluminium, Aluminium cast and wrought alloys Si<5% (long-chipping) Pure Copper, Copper alloys and copper-zinc alloys (long-chipping)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The open frame XY stages KT are especially designed to provide high accuracy in compact dimensions. By the modular concept, they can be equipped with different motors and measuring systems. The open frame XY stages are particularly suitable for transmitted light applications. normalized aluminium alloy, black anodized cross roller guides, anti-backlash pre-loaded when equipped with motorized drives, anti-backlash pre-loaded ball screws are used when hand driven, with quick-release for coarse adjustment and +/- 5 mm fine-pitch thread plane parallel glass top to put on the specimen

Request for a quote

TELEDYNE ICM

Belgium

The CP160D is the lightest and most compact generator of the CPSERIES. Featuring a built-in Beryllium window, it is the perfect generator for the inspection of light alloys such as aluminum, magnesium or fiber based materials like glass and carbon, as well as the greater thickness of steel. In fact, with its penetration capacity that is capable of reaching up to 37 mm of steel, the CP160D is able to execute many different types of NDT tasks without the need to ever have to add extra accessories.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Eurobalt Engineering provides die casting services for the companies that manufacture lighting products for different industries. Our company mainly produces street lamp housings and cooling radiators using aluminium alloys for LED lighting systems manufacturers. Our die casting services are exceptionally cheap and high-quality – aluminium parts turn out cheaper than if similar parts are produced using other methods. Although aluminium die casting parts are not so durable and long-lasting, they are also lighter and have a high thermal conductivity, which is very important in the production of LED lighting systems.

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

TWSD LONG REACTION ARM (TWSD-LRA) Tubular extension arm for TWSD wrench: in-line reaction outside wrench profile Replaces standard reaction arm – quick release pin locking Steel/light alloy construction (reaction flat machined on tube end) Can be cut down to suit specific length Available for full range of tool sizes

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

TWHC LONG REACTION ARM (TWHC-LRA) Tubular extension arm for TWHC wrench: in-line reaction outside wrench profile Replaces standard reaction arm – quick release pin locking Steel/light alloy construction (reaction flat machined on tube end) Can be cut down to suit specific length Available for full range of tool sizes

Request for a quote

YIBAI LED LIGHTING

China

Housing: rugged and light-weight aluminum alloy functioning as platformfor light bars and driver compartment, and lighting control interfaces (e.g.Zhaga sensor ready connector, NEMA receptacle). Mounting bracket: powder-coated aluminum alloy. Lightbars: extrusion aluminum heatsink, aluminium PCB with 18 LEDs mounted, UV resistant polycarbonate 18-in-1 optic lens cluster, micro terminal block on PCB, and connector for toolless wiring. IP67 and IK10 rated. Hardware: 304-grade stainless steel nuts.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Hamilton Precision Metals is the world leader of precision-rolled foil and ultra-light gauge strip in any alloy. This includes stainless steel foil, titanium foil, nickel foil, copper based foil, cobalt based foil, Constantan® foil, Evanohm® foil, and many other alloys. Metal foil is generally defined as strip 0.004” (0.1016 mm) and below. Cold rolling strip to these extremely thin gauges demands extensive rolling expertise to manufacture with precision and consistency. Foil in Any Alloy We offer the broadest portfolio of almost every high performance alloy made today. Additional alloys are available upon request, contact us today! Stainless Steels Nickel Based Alloys Copper Based Alloys Cobalt Based Alloys Commercially Pure Titaniums Strain Gage: Constantan®, Evanohm®, Tightest Tolerances and Thinnest Gauges in the Industry We custom roll metal foil in nearly any alloy and specialty metal to the tightest tolerances and thinnest gauges

Request for a quote

INO MACHINERY

Turkey

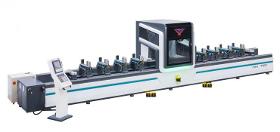

The Compact Design CNC profile machining center with 4 controlled axes X-Y-Z-A. The machine is mainly designed for processing on aluminium profiles. Apart from aluminium, it can also process any kind of light alloy profiles with the help of dedicated customized cutters. The bridge that is carrying the high speed electrospindle is moving on linear guides by the brushless servo motors independently from the drive and process any kind of shape on the profiles. The electrospindle can rotate from 0 to 180 degrees independent from the drive and machine in any angular position and change the tools from the tool changing magazine with 7 positions. The CADCAM software is a customized tool for “ino machinery” profile machining centers. The pneumatic referance point tilt up and down automatically according to the machine’s working cycle.

Request for a quote

INO MACHINERY

Turkey

The Compact Design CNC profile machining center with 4 controlled axes X-Y-Z-A. The machine is mainly designed for processing aluminium profiles. Apart from aluminium, it can also process any light alloy profiles with the help of dedicated customized cutters. The bridge carrying the high-speed electro spindle moves on linear guides by the brushless servo motors independently from the drive and processes any shape on the profiles. The electrospindle can rotate from 0 to 180 degrees independent from the drive and machine in any angular position and change the tools from the tool changing magazine with 7 positions. The CADCAM software is a customized tool for “ino machinery” profile machining centers. The pneumatic reference point tilts up and down automatically according to the machine’s working cycle.4 pieces of profile clamping units are positioned manually by the operator according to the places that the CADCAM decides.

Request for a quote

INO MACHINERY

Turkey

The CNC Panel Working Machinery specialized for machining aluminium composite panels. Also called in the market as ACP panels or ACM panels. The machine first grooves and then cuts the aluminium composite panels by using cutter bits using 2 high speed spindle motors, clamps the panels by vacuuming with a vaccum table and vacuuming pump, extracts the swarf coming out from the panel by a dust extraction system. All axes are moving on linear guides and moved by servo motors with reducers controlled by a real CNC controller. The machine can process light alloy materials such as: aluminium composite panels, HPL, aluminium panels up to 20 mm of wall thickness, bakelite, copper, acrylic, plexi-glass and etc. The machine has a very technologic vacuuming table made from plastic. The user does not need to isolate the table with gaskets like in the old system. The vacuuming is isolated inside the vacuuming system under the table and has a very high clamping force.

Request for a quote

YILMAZ MACHINE

Turkey

AIM 7510 is 5-axis servo controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminum & PVC profiles, light alloys in general and thin walled steel profiles. Efficient and economic processing on the six sides of the profiles is possible with this fully automatic machining center. The moveable turret type of tool magazine equipped with12 standard tools provide a fast tool change.It is housed in the mobile gantry to minimize the tool change time. An additional magazine for the saw blade with 350 mm dia. ensures the ease of machining on the exterior applications of the profiles. The machine can be used in tandem mode, a work method that allows machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run “while the machine is operating. Automatic clamp recognition and clamp positioning is available.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 7510 is 5-axis servo controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminum profiles, light alloys in general and thin walled steel profiles. Efficient and economic processing on the 5 sides of the profiles is possible with this fully automatic machining center. The moveable turret type of tool magazine equipped with12 standard tools provide a fast tool change.It is housed in the mobile gantry to minimize the tool change time.An additional magazine for the saw blade with Ø350 mm ensures the ease of machining on the exterior applications of the profiles. The machine can be used in tandem mode, a work method that allows machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run “while the machine is operating. Automatic clamp recognition and clamp positioning is available.

Request for a quoteResults for

Light alloy - Import exportNumber of results

48 ProductsCountries

Company type

Category

- Wheel rims, vehicle (8)

- Lubricants, industrial (5)

- Tools & Hardware (5)

- Aluminium alloys (4)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (4)

- Milling - machine tools (3)

- Foundries - copper, bronze and brass (2)

- Lighting, street, industrial and commercial (2)

- Screws (2)

- Bearings - ball, needle and roller (1)

- Cars, used (1)

- Detergents and soaps - professional (1)

- Electricity generators (1)

- Forming - steels and metals (1)

- Measurement - Equipment & Instruments (1)

- Pad printing (1)

- Sawing machine tools (1)

- Spotlights (1)

- Steel sheets and strips (1)