- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- product and process control

Results for

Product and process control - Import export

Q-INTERLINE A/S

Denmark

InfraQuant offers an easy-to-use platform to streamline QC operations and produce analytical results of high and trusted quality. We understand that the supervisor wants a highly configurable tool, whereas an operator is looking for simplicity. That is why InfraQuant has balanced both these aims and offers an advanced configuration module as well as an easy front interface to run the daily routines. The front-end Wizard guides the operator through the analysis sequence with information messages, warnings and reminders. The Wizard ensures consistent results independent of operator skills and experience. Our philosophy is to minimise the use of the mouse and work from a “next-next-next-ok” design perspective. > Software highlights: - Runs on up-to-date windows 10 - Intuitive and easy to use without training - The choice between multiple user languages - Easy link to AnalyticTrust for easy instrument surveillance and QA - Easy link to LIMS

Request for a quote

Q-INTERLINE A/S

Denmark

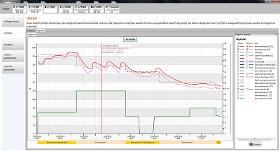

InSightView is the frontend software to monitor and control the daily operation of the InSight Pro analyser concept. InSightView offers a full overview of the measurement results and validity, running average, trend curves, etc. in a simple and efficient way. With the use of colour codes, set against fully configurable criteria, it is quick and easy to obtain information about the status of the production and the analyser with just a brief glance. InSightView is designed to be operated by process personnel with a multi-language user interface. > Software highlights: - Real-time analytical results - Built-in process stability indicator - Calibration sample relevance indicator - Link to AnalyticTrust for easy instrument surveillance and QA - Intuitive and easy to use without training - Select between multiple languages - Runs on Windows 10 pro

Request for a quote

Q-INTERLINE A/S

Denmark

The InSight Pro concept offers a modern and future-ready in-line analyser solution. We have taken all unnecessary complexity out of the product to offer a high-end solution that is easy to purchase, install and run for years. InSight Pro offers measuring devices adapted for various sample types. One or two measuring points can connect to the analyser via flexible optical fibres. > What can you achieve: - Faster start-up - Stable process - Produce closer to target - Less waste and rework - Full traceability - Energy optimisation - Predictability > The InSight Pro systems offers the customer : - A maintenance-free system - One or two measuring points - Full CIP/SIP compliance - IP65 protection for easy installation - 3-years warranty - Choice between five configurations - Built-in 24/7 surveillance - Same analyser engine used at-line - Operator-friendly software – InSightView

Request for a quote

Q-INTERLINE A/S

Denmark

We deliver on a promise to eliminate the challenges with the flow systems in traditional milk analysers. There is no cell, no wear and tear on instru-ment parts, no risk of blocking, no air in the system, no need for special cleaning and no drift on the measurement cell. DairyQuant GO eliminates the use of chemical solutions and there is no need for standardisation. The DairyQuant GO can measure highly challenging samples such as whey concentrate, yoghurt mixes and milkshakes through to cream, milk, and skim with no cleaning between samples and no fuss. With the patented Pivette® sampling method you can run the samples in any order you wish – imagine a precise cream analysis, then a mascarpone sample to end the run with a high precision determination of low fat content in a whey sample – no carry over! The DairyQuant GO complies with the new IDF standard ISO 21543 I IDF 201: 2020 – Milk and milk products – Guidelines for the application of near infrared spectrometry.

Request for a quote

Q-INTERLINE A/S

Denmark

The Quant, a unique state-of-the-art FT-NIR spectrometer engine, is used for everything we do! We develop, patent, and produce many different accessories to handle nearly all types of samples and materials, but the base analyser remains the same. > The Quant based system offers the customer: - One proven platform - One spectral format to handle across all applications - Same spare parts fit all analysers - Same software across all applications - Same LIMS interface for all applications - Easier operator training - Same link to AnalyticTrust surveillance & support platform - 3 years warranty - No scheduled maintenance - Lamp life on average 10 years - Internal laser lasts for the instrument lifetime - Highest spectral performance in any commercial FT spectrometer! - More stability and better accuracy - Choice between 10 accessory configurations - Intuitive multi language user software – InfraQuant

Request for a quote

Q-INTERLINE A/S

Denmark

FT-NIR instruments need supervision. They must be checked and re-calibrated at regular intervals in order to maintain the precision required to sustain the business case. Some results are used in Big Data interpretations and internal data flows and the effect of lost data quality is almost certainly bad data out. In daily operation AnalyticTrust manages a customisable schedule of verification activities very much like a workflow management tool. Validation must be performed at regular intervals and reminders are sent to operators. In cases of non-compliance escalation emails are sent to management. AnalyticTrust integrates directly to instruments and computers, receiving the results of measurements and storing them in the instrument database. This allows AnalyticTrust to perform analysis of the validation results and predict instrument degradation and failure. Automatic Performance Degradation detection is used to request unscheduled instruments calibration or parts replacement.

Request for a quote

Q-INTERLINE A/S

Denmark

The chemical industry uses spectroscopy as a regular tool in many forms such as UV-VIS and FT-IR. The industry adapted to the NIR and especially the FT-NIR technology in the beginning of the 90’ies and our base technology has been utilized ever since in very diverse applications. The industry is in many areas regulated by legislation demanding that release of products can only be done by the official methods, but the industry has learned to utilize the options to run in-process analysis and control the process. That is where Q-Interline and our partners can supply solutions. We offer an analyser for the laboratory as well as the process and we have extensive experience in designing and building tailor-made optical cells and probes in a wide range of materials. Having full control of the entire manufacturing process of probes, cells and optical fiber cables allows us to full-fill many demanding applications.

Request for a quote

Q-INTERLINE A/S

Denmark

This business area covers a vast range of applications and has been a natural part of our business since 1996. Whereas food products classically have a very high volume and a lower price per ton, the ingredients area is characterised by somewhat lower volume but a clearly higher price per ton. Both scenarios may greatly benefit from process optimisation, often following two different strategies. To optimise the process, a bias-free accurate insight into process dynamics and variations is needed. Many of our solutions have been developed together with customers seeking new innovative and value adding answers to well-known challenges, and our unique combination of curiosity and the skills present in our team has formed the basis for new products. Q-Interline’s analyser and project model are ideally suited to support exactly that, and we offer fast and reliable laboratory at-line units operated by process operators, as well as real-time in-line analysers.

Request for a quote

PARSMEGA MAKINA

Turkey

It has wide usage opportunities in all areas where engine use is intense, such as production lines, factories, smart buildings, treatment facilities, pump stations. Our panels are designed considering the ease of operation and maintenance of MCC, with standards-compliant solutions for production lines and control that require process control. Our project support, the solutions we produce for control systems with conventional or "process controllers", our knowledge and experience are an important privilege we offer to our customers. Using the right equipment or system in the right place and our complete solutions made with quality equipment are part of our tradition of achieving important criteria such as operational safety and investment efficiency for the benefit of the end user.

Request for a quote

MINEBEA INTEC GMBH

Germany

The PC-based software Batch-PMS enables the operation, monitoring and control of batch-oriented and recipe-based production processes. The integrated control system makes it easy to automate weighing and process batch applications. The software Batch-PMS can be easily integrated into existing network and system infrastructures of various industries. It includes modules for process control, production management, recipe management, data management and many further options. Your benefits: — Simple and modular operating concept including multi-user operation — Easy integration into existing network and system infrastructures — Outstanding connectivity — High data safety including integrated backup functionality

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The software for process monitoring from FESSMANN is the simple answer to complex production processes with its operatorfriendly, Windowsbased control. FOOD.LOG provides an overview of all data required for quality assurance of your products. The ergonomic, intuitive user guidance and storage of all data in a database make it simple for FOOD.LOG users to monitor multiple systems at once. Choose between FOOD.LOG basic, professional and enterprise in order to meet your individual demands to production monitoring. FOOD.LOG will make sure that you miss nothing. All system and operating conditions can be documented precisely. Processrelevant data such as chamber and core temperatures, Fvalue, process duration or relative humidity are recorded by the program and saved. FOOD.LOG permits precise production control and evidence, also according to DIN ISO 9000. You can comfortably create and edit goods programs from anywhere.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

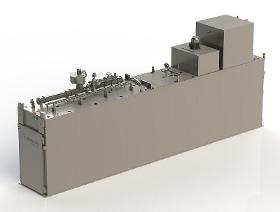

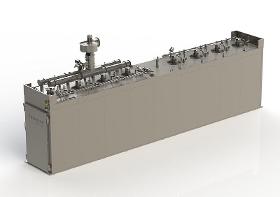

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The TF3000 combines the Turbomat T3000 and the intensive cooling system IK3000 in a single closed system. This means one thing most of all Best output per chamber part for the shortest process times. The automated transport system not only reduces operating costs, but also increases production capacities in the system. Maximum output per chamber part Production justintime, controllable and reproducible processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The RESISTOMAT® model 2329 is particularly suitable for fast measurements of low resistances in automated processes. Up to 50 measurements per second can easily be performed. The device complies with the latest CE guidelines and is designed for laboratory use as well as heavy-duty industrial applications. A 2-fold and 4-fold comparator with switching outputs has been included for classifi cation and selection; this feature is particularly useful for serial tests. One special application involves the measurement of contact resistances (dry-circuit measurement); the load voltage in this case is limited to 20 mV in order to prevent fritting (DIN IEC 512). The RS232 (standard) and IEEE488, USB and Ethernet (option) computer interfaces allow the set-up of fully automatic testing stations. The PLC interface allows easy integration into your production process control.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

CIC will be happy to support you in planning, securing, controlling, monitoring and optimizing your quality management, e.g. with: advanced quality planning supplier quality purchased part quality component qualification product engineering Supplier Audit Internal audits Process monitoring and process optimization Production control and monitoring at the supplier bottleneck coordination production readiness tool design Tool tracking mold trials Gauge concepts and gauge acceptance component measurements Resident Engineering Task Force Abbreviations such as APQP, PEP, FMEA, PPAP, 8-D, 5Why are not foreign words for us but common tools.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

BN is a material with non-wet feature. So molten metal won’t be sticked onto the nozzle. Additionally, Boron Nitride ceramic is a kind of refractory ceramic with low expansion and high thermal conductivity. These features make it to be an ideal choice as atomizing nozzles. It's very easy to be machined to custom design with precision and tight tolerance because of its machinability. Boron Nitride Ceramic BN Nozzles Performance: 1.The optimized formula and unigque process make it highly resistant to thermal shock and high-temperature creep.Maximum using temperature 1700°C. 2.Low thermal expansion coefficient,no cracking or deformation during use. 3.Strong erosion resistance,wear resistance and metal corrosion resitance.Long service life. 4.Good raw materials,process control,product stability. 5. It is used in Amorphous Ribbon Making and amorphous nozzles.

Request for a quote

ADS-TEC INDUSTRIAL IT GMBH

Germany

The new MES9000 series is an innovative HMI solution, covering three application areas and production environments. Whether as a shop floor terminal, a machine panel PC, or as a rugged shop floor terminal for tougher working conditions - the MES9000 is versatile. The devices were developed as a hardware response to the growing demands of modern visualization software in the automation industry. The modern HMIs in this series are characterised by their performance, connectivity and user-friendliness. Plant and machine operators can now visualize production processes more clearly and control them more easily. Furthermore, the MES9000 enables efficient collection of operational and order data. Thanks to a sophisticated fastening concept, the MES9000 series can be integrated into any production landscape. Peripheral devices such as a keyboard and scanner holder can be quickly connected thanks to the large number of interfaces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FATRA A.S.

Czech Rep.

Regranulate One of the reasons for using secondary raw materials (plastic waste) is their economic advantage caused by reduced material exigency and generally lower prices of inputs – recycled products/re-granulates. Using the higher amount of recycled product in products as an alternative to primary resources usually leads to their lower final price, which contributes to better competitiveness of products on the market. We produce re-granulates for injection moulding, blow moulding, and extrusion on modern re-granulating lines. Based on customers’ requirements, we can produce re-granulates with required melt flow index, of various colours, including re-granulates with filling compound content. In the production, we process internal and external waste. Product advantages continuous quality of inputs – secondary raw materials directly from the production stable production process with continuous control optional re-granulate colouring, or adding additives directly in the...

Request for a quote

ZETEK SP. Z O.O.

Poland

The certification of gauges is based on checking that the instrument maintains the prescribed measurement tolerances and MSA processes that confirm the stability of the measurement process of the gauge used in different conditions and by different people. Tests and control and measurement devices undergo the process of checking the current state, and then we carry out the calibration process and recertification. We carry out the certification and calibration process of the gauges in accordance with the procedures resulting from ISO 17025 , which confirms the credibility of our work. At the client's request, we perform work in accordance with the requirements and processes resulting from the individual features or parameters of a given measuring instrument. Calibration of the gauges Calibration is an integral part of the construction and production processes of control and measurement devices and gauges, and is also used during service or repair work.

Request for a quote

JS INTEGRAL SP. Z O.O.

Poland

JS INTEGRAL manufactures control cabinets based on documentation provided by the customer (electrical and mechanical) or other technical arrangements, complying with the relevant requirements of PN-EN standards, including mining standards. Our control cabinets are used: •for power distribution and protection of electrical equipment against short-circuits, overvoltage and overload, •to control the operation of motors, pumps, fans, air conditioning, drives and other electrical appliances, •to control production processes in production and energy production / distribution companies, •to signal, control and monitor the performance of machinery and equipment, and technological processes in industry and power industry, •to implement control and monitoring functions in BMS and HVAC systems.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

one- stop service Free engineering support, help you optimize your design based on rich machining experience. 5-7 days rapid prototype,speed up your shecdule in time. Sourcing normal commercial components like nuts,spring and bearing Updating production process every stage, let you control the production state here Arranging and tracking shipment

Request for a quote

INFICON AG

Liechtenstein, Principality of

Tool Management, Process Specific INFICON Sensor Integration and Analysis Systems provide process verification and control, including run-to-run control of key process parameters for process optimization and immediate and automatic feedback to the process equipment or a process engineer on any faults detected and their probable cause. FabGuard Sensor Integration and Analysis System takes data from in situ sensors, integrates that data with data from the process equipment itself, and condenses and analyzes it to provide the process engineer with actionable information. Alternatively, the engineer can choose to have FabGuard automatically send control commands directly to the process equipment. Powerful Data Management for Enhanced Productivity Make your fab's data work for you. The FabGuard Sensor Integration and Analysis System enhances tool productivity, by providing process control, and reducing losses from process drift, contamination, tool malfunction, or unnecessary test...

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

The VTX2 vortex meter is used for flow and volumetric measurements of conductive and non-conductive fluids, gases and vapours in all industrial branches. Applications include volumetric measurements for balancing (compressed air systems, heat carriers, vapours, chemical products, for example), process control and high throughput applications. Technical specifications • DN 15 - 300 (higher on request) • PN 10 - 40 • Flow rate 0,4 - 20000 m³/h • Measurement accuracy Gas and Steam: ± 0,9 % • Measurement accuracy liquids: ± 0,6 % • operating temperature according to design -40°C to +260°C, optional to 450°C Accessories • Strainer • gas separator • processing peripherals Advantages • high reliability • overloadable • interchangeable pressure sensor (optional) • measurements in harsh environments (vibration) is possible • good results even at low pressures and low volume flows

Request for a quote

INFICON AG

Liechtenstein, Principality of

Tool Management, Process Specific INFICON Sensor Integration and Analysis Systems provide process verification and control, including run-to-run control of key process parameters for process optimization and immediate and automatic feedback to the process equipment or a process engineer on any faults detected and their probable cause. FabGuard Sensor Integration and Analysis System takes data from in situ sensors, integrates that data with data from the process equipment itself, and condenses and analyzes it to provide the process engineer with actionable information. Alternatively, the engineer can choose to have FabGuard automatically send control commands directly to the process equipment. Powerful Data Management for Enhanced Productivity Make your fab's data work for you. The FabGuard Sensor Integration and Analysis System enhances tool productivity, by providing process control, and reducing losses from process drift, contamination, tool malfunction, or unnecessary test...

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our precision metal strip products are custom-made in biocompatible alloys for implantable medical devices that improve quality of life for patients around the world. We work in partnership with Hamilton Precision Metals to manufacture innovative metal materials that enable smaller, lighter and higher performing medical implants. Superior Titanium Strip for Implantable Medical Devices We have developed proprietary practices for the successful reduction of Titanium Grade 5 (6Al-4V) and Titanium Grade 23 Alloys (6Al-4V ELI) to thicknesses of 0.0039” (0.10mm). Our process results in a finish much superior to alternative methods of etching or grinding strips to gauge. This surface finish and gauge control translates to improvements in finished product quality as well as process controls during drawing, stamping, etching or laser cutting. These alloys are offered in the fully annealed or the as-rolled tempers.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser produces highly precise presses for the metal forming industry, thus increasing productivity, quality, and lifetime and decreasing overall operating costs. ANDRITZ Kaiser has delivered more than 8,000 presses for numerous customers world wide, each different in its application. A large number of factors have to be taken into account when deciding on the right press: technical requirements from the product, expected productivity, technical requirements on the press line, integration into the existing production lines, fixed and running costs, process control, fast availability of maintenance/service, availability of spare parts – all these considerations influence mainly the total cost of ownership. Our press solutions are: Conventional high speed presses from 630 kN up to 4,000 kN Conventional stamping and deep drawing presses from 1,000 kN up to 8,000 kN Cutting presses from 1,600 kN up to 6,300 kN Heavy presses from 10,000 kN up to 25,000 kN Servo presses from...

Request for a quote

RUHLAMAT GMBH

Germany

Test systems and inspection systems form an integral part of most of the automated solutions we employ. Each assembly process is usually followed by an inspection process so that the highest quality requirements can be satisfied. Both laboratory as well as stand alone or inline series inspection systems (EOL) have already been widely implemented by ruhlamat. Inspection results (product/process data) are documented in individual or customer-specific databases (traceability). Seamless traceability of product and process data Inline process control and monitoring Efficiency through timely trend control 100% inspection

Request for a quote

BIOSYYD

Lithuania

With customizable (25-90%) potency, our CBN Distillates are made with the highest level of quality, consistency and compliance to ensure the same for your finished product. Their highly controlled processing environments and refinement procedures guarantee industry-leading results. Never synthetic and never fortified, they are gently refined to remove all other unwanted compounds but still contain minor cannabinoids such as CBG, CBN, CBC. All other hemp plant matter, except oils, is removed from the distillate, including waxes, chlorophyll and more, resulting in CBN Distillate that is highly concentrated. This degree of purity makes dosing accurately while the symbiosis of minors makes the product more effective.

Request for a quote

BIOSYYD

Lithuania

With customizable (25-90%) potency, our CBG Distillates are made with the highest level of quality, consistency and compliance to ensure the same for your finished product. Their highly controlled processing environments and refinement procedures guarantee industry-leading results. Never synthetic and never fortified, they are gently refined to remove all other unwanted compounds but still contain minor cannabinoids such as CBG, CBN, CBC. All other hemp plant matter, except oils, is removed from the distillate, including waxes, chlorophyll and more, resulting in CBG Distillate that is highly concentrated. This degree of purity makes dosing accurately while the symbiosis of minors makes the product more effective.

Request for a quoteResults for

Product and process control - Import exportNumber of results

51 ProductsCountries

Category

- Measurement and control instruments (9)

- Alcohols, phenols and derivatives (3)

- Cooking and smoke-curing equipment for delicatessens (3)

- Control boxes - electric (2)

- Aluminium sheets and bands (1)

- Bags, plastic (1)

- Ceramics, industrial (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemical industry - machinery and equipment (1)

- Cleaning machines, industrial (1)

- Food Processing (1)

- Forming, rubber - machinery (1)

- Freeze drying - machinery and equipment (1)

- Gears (1)

- Milling - machine tools (1)

- Nozzles - ferrous metal (1)

- Oils, cooking - machinery and equipment (1)

- Plastics - packaging (1)

- Precision measuring instruments (1)

- Rail and road transport (1)