- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- equipment operating

Results for

Equipment operating - Import export

POLYTECH GROUP

Russia

Vessels designed for gases, liquefied gases, dissolved under pressure, for vapors and liquids used for fluids of groups 1 and 2 Boilers intended to produce hot water, temperature of which is over 110 °C or vapor, excessive pressure of which is over 0,05 MPa as well as directfired vessels Pipelines designed for gases, vapors and liquids used for fluids of groups 1 and 2 Equipment elements (assembly units) and components hereto that can withstand pressure Valves designed for equipment with fluids of groups 1 and 2 Indicating and safety devices Pressure chambers (except for medical singleseated ones) Protecting devices and appliances Main pipelines, intrafield and local distribution pipelines intended for transportation of gas, oil and other products except for equipment used at the pressure regulation stations or compressor stations

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Rolling stock, integrated manufacturing and testing equipment, the mobility of our trade specialists are just some of the key assets we deploy to comprehensively manage your requirements, whatever your needs or the time of year. At the same time, we also perform maintenance operations on your equipment at your premises: safety compliance, refurbishment and repair, welding, metal work, electrical and mechanical maintenance, assembly and retrofitting. Our qualified employees are at your disposal and are fully accustomed to working on site with customers, whether independently or with teams working in other trades. Our teams have all the necessary clearances and qualifications to provide you with quality facilities, while working in compliance with safety regulations and your internal procedures.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

When constantly monitored and accurately analysed, this data can be used to anticipate unexpected breakdowns, to schedule preventive maintenance operations, and even to identify the weak points of production facilities and continuously improve their efficiency. No more inconvenient production shutdowns. No more preventive replacement of equipment that can operate effectively until the next maintenance campaign No more excessive and unjustifiable preventive maintenance costs.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Numerically-controlled hydraulic press brake, numerically-controlled hydraulic shearing machine, numerically-controlled machining centres, numerically-controlled lathes and milling machines, mortising machines, presses, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting workstation, paint booth, assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment, testing and programming workstations, etc. With our diverse range of facilities and modular covered areas, we can manufacture practically any type of installation or equipment, with unlimited space and technological expertise. Our multidisciplinary team of highly qualified specialists, combining long-standing experience with the technical skills of youth, guarantees the optimal operation of our equipment and the quality of the facilities delivered to you.

Request for a quote

TEMA METALURJI SAN TIC LTD STI

Turkey

-INDUSTRIAL VALVES SECTOR -WCB CASTİNG -QUALITY RAW MATERIALS -EXPERIENCED MASTERS -WELL-EQUIPPED LABORATORY

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

A flow valve is a critical component in various systems where the regulation of fluid flow is necessary. It’s designed to control the rate at which fluid passes through a system, ensuring that the flow matches the requirements of the application.Flow control valves are essential in industrial usage, hydraulic systems, and pneumatic systems. They play a crucial role in regulating the flow of fluids, ensuring optimal performance and efficient operation of machinery and equipment. Control valves can be actuated in various ways, including pneumatically, hydraulically, or with electric motors. Some valves, known as automatic control valves, do not require an external power source and operate solely on fluid pressure.When selecting a flow control valve, it’s important to consider factors such as flow rate and pressure requirements, material compatibility, and environmental conditions.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used in valve fitting.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in valves.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These Stainless bush automatic turning parts, application for valves compoment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in valve.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used in Hydraulic valve assembly.

Request for a quote

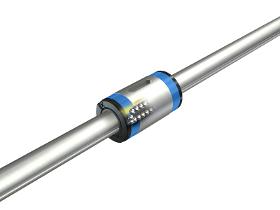

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

CLube Linear Ball Spline MAG incorporates CLube in the IKO Ball Spline G. MAG is used primarily in semiconductor/liquid crystal related manufacturing equipment where harsh operating conditions and high acceleration/deceleration are common. CLube provides longterm, maintenance free operation, and reduces the cost of the whole system by eliminating the oil supply mechanism and reducing the running cost and hours required for lubrication.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat valve type 7015 is ideal for applications in food and beverage production. The valve can be used to shut-off product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat control valve type 7025 with integrated digital positioner is specially adapted for use in the food and beverages production. Suitable for controlling product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated angle seat valve is the extremely reliable allrounder in valve technology and is predestined for very high switching capacities. In stainless steel design for neutral and aggressive media but also for a wide range of temperature applications suitable. The angled seat design offers a high flow rate.

Request for a quote

BORSIG GMBH

Germany

Today’s demand for increased efficiency and flexibility that comes along with higher temperatures, increased pressures and high cycling requires specific engineered valves. We design and manufacture high quality trunnion mounted ball valves tailored to your specific control processes by using customized control discs. Our control valve product line is engineered to suit very high differential pressure applications giving you an exceptionally high rangeability for your plant operation.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pad mounted valve with stainless steel body for safe shut-off of normal and aggressive media, for mounting on valve blocks.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated globe valve type 7027 with integrated positioner for control applications with neutral to highly aggressive media. The straight design enables a highly efficient and very simple insulation of the valve body as well as the welded-on pipeline.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated globe valve type 7017 in stainless steel design for on-off applications with neutral to highly aggressive media. The straight design enables a high flow rate as well as a highly efficient and very simple insulation of the valve.

Request for a quote

FRITZ GYGER AG

Switzerland

SMLD 300, THE SMALLEST With a minimum grid width of just 4.5 mm (with a special coil package even only 4 mm), the micro valves SMLD 300 are suitable for the tightest of spaces. Low-viscosity media can be dispensed with small flow rates. This type of valve offers a small internal volume of only 25 µl. VALVE COILS The valve coils are removable and available in different versions. They are optimised for very fast actuation times and minimal size. VALVE INSTALLATION Fastening type cylindrical: Grid width with highest resolution, small size. Suitable to our adapter nozzles. The thread fastening is designed to allow an easy exchange of the micro valves. especially suited when the micro valves should be as easy to exchange as possible. The micro valve can be exchanged quickly and without dismantling the entire valve holder and without disconnecting the electric connections.

Request for a quote

FRITZ GYGER AG

Switzerland

SMLD 300G, THE FLEXIBLE ONE With a minimum grid width of 6 mm, the SMLD 300G is very space-saving, while offering maximum flexibility. These micro valves are suitable for a wide range of viscosities and are available in many configurations. Valve holder with integrated heating can also be combined with it. The internal volume is 65 µl. The R (Resistant) type offers crucial benefits in regards of corrosion and the handling of aggressive medias, compared to SMLD 300G, but remains fully compatible in size and function for all SMLD products and components. VALVE COILS The valve coils are removable and available in different versions. They are optimised for very fast actuation times and minimal size. VALVE INSTALLATION Fastening type cylindrical: Grid width with highest resolution, small size. Suitable to our adapter nozzles. The thread fastening is designed to allow an easy exchange of the micro valves. especially suited when the micro valves should be as easy to exchange as possible.

Request for a quote

OPET LUBRICANTS

Turkey

Fullgear CT Series, is a high performance gear oil which is developed for automatic or automatic/manual (powershift) transmissions, final drives, wet brake and clutch systems of construction equipments under extreme operating conditions. It is developed for leading equipment manufacturers, especially Caterpillar construction equipments under extreme operating conditions.

Request for a quote

OPET LUBRICANTS

Turkey

Fullgear CT Series, is a high performance gear oil which is developed for automatic or automatic/manual (powershift) transmissions, final drives, wet brake and clutch systems of construction equipments under extreme operating conditions. It is developed for leading equipment manufacturers, especially Caterpillar construction equipments under extreme operating conditions.

Request for a quote

OPET LUBRICANTS

Turkey

Fullgear CT Series, is a high performance gear oil which is developed for automatic or automatic/manual (powershift) transmissions, final drives, wet brake and clutch systems of construction equipments under extreme operating conditions. It is developed for leading equipment manufacturers, especially Caterpillar construction equipments under extreme operating conditions.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

Temperature is one of the most measured physical parameters. Despite this, precise temperature measurement is one of the most difficult tasks in motor technology. To meet the constantly increasing requirements for improved motor performance, higher efficiency and reduced emissions, it is necessary to use reliable and precise sensors in modern motor control systems. The increased requirements over the last few years regarding measurement accuracy and reliability of temperature measurements has meant that many equipment operators must reconsider the suitability and performance capacity of their temperature measurement equipment. Resistant thermometers can be used between -200 °C and +850 °C. An important common property is that their output parameters are available in the form of electric signals that can be relatively easily transferred to measurement and control instruments for processing, storage and display.

Request for a quote

COSIFER - CARPENTERIE METALLICHE LAVORI IN FERRO ED ACCIAIO

Italy

Our dispenser holder can be conveniently installed both indoors and outdoors. The holder is made entirely of brushed stainless steel and equipped with a pedal-operated waste bin. The door also consists of 2 glass shelves and a plastic liquid dispenser with an anti-slip closure. The stainless steel construction makes our door robust, while the other options make it convenient and innovative.

Request for a quote

FERPLAST SNC

Italy

FPX800 LEVER HAND DISPENSER - FOR GUMMED PAPER Manual dispenser suitable for measuring and cutting the gummed paper. Lever operation. Equipped with automatic cutting blade and water tank. The length of the paper strip is adjustable by lever with adjustable stroke. By simply pressing the lever, a strip of wet paper is obtained, ready to be applied to the box. The wetted paper ensures a much higher seal than the adhesive tape and provides a clear indication on the tampering of the box. Unlike the adhesive tape, to open the box it is necessary to break the paper and it is not possible to close it again.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

CF 30 G equipment is supplied completely assembled and ready for operation. The dust collection unit is suited for intermittent operation only, because regular cleaning of the pocket filter element in certain intervals is an absolutely must for the proper operation of the equipment. The cleaning intervals will depend on the operating conditions and must be established by experience. Normally cleaning intervals will be between operating times of 30 minutes to two hours. It is a prerequisite for sufficient and intensive cleaning of the filter cloth that dust collecting is interrupted during cleaning to achieve static pressures on the filter material. A retention time of 1 - 2,5 minutes between the end of the suction and the beginning of the cleaning process is therefore required. The filtered air must be removed outside - do not lead back to closed rooms!

Request for a quoteResults for

Equipment operating - Import exportNumber of results

241 ProductsCountries

- Germany (69)

- United Kingdom (29)

- Turkey (25)

- Russia (23)

- France (14)

- Spain (13)

- Ukraine (13)

- Italy (10)

- Czech Rep. (6)

- Belgium (5)

- China (5)

- Netherlands (4)

- Hungary (3)

- Portugal (3)

- Switzerland (3)

- Bulgaria (2)

- Lithuania (2)

- Poland (2)

- Slovenia (2)

- Austria (1)

- Belarus (1)

- Finland (1)

- Liechtenstein, Principality of (1)

- Romania (1)

- South Korea (1)

- Sweden (1)

- Thailand (1)

Company type

Category

- Industrial valves, operating equipment (89)

- Processing and recycling of waste (7)

- Water retreatment - equipment and installations (7)

- Lubricants for cars (4)

- Oils, industrial (4)

- Lubricants, industrial (3)

- Lubrication equipment and machinery (3)

- Motor mechanics - hand tools, non power (3)

- Unit heaters (3)

- Batteries (2)

- Commercial training (2)

- Drainage systems and equipment (2)

- Dry cooling towers (2)

- Dust extraction installations and equipment (2)

- Electronic components (2)

- Fire prevention equipment (2)

- Food Industry - Machines & Equipment (2)

- Fountains, street and park (2)

- Import-export - Computers (2)

- Import-export - oil (2)