- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser distance sensors

Results for

Laser distance sensors - Import export

MICRO-EPSILON

Germany

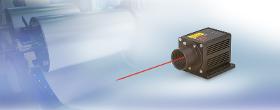

The high-performance optoNCDT ILR2250 laser distance sensor is used whenever large measuring ranges and high accuracy are required. The optoNCDT ILR2250 can be installed at distances up to 100 m, and even up to 150 m with a reflector film. This sensor impresses when measuring dark, structured and poorly reflecting surfaces, while providing stable measurement results to millimeter accuracy. The optoNCDT ILR2250 laser distance sensor is used in transportation, logistics and conveyance technologies as well as automation and the metals industry. This is where the sensor enables reliable measurement results even when it is, e.g., installed at a safe distance from heat emitting measuring objects. In addition, difficult-to-access places via mirrors or through glass sheets can be detected.

Request for a quote

MICRO-EPSILON

Germany

The new optoNCDT ILR1171-125 laser distance sensor is used for distance measurements up to 270 m and particularly impresses in outdoor measurements. Due to the laser time-of-flight principle with infrared light and a measuring rate of up to 40 kHz, high energy pulses are achieved, allowing stable measurements with very good signal quality. In addition, this better compensates for interfering influences such as fog or rain. The high temperature stability allows applications at temperatures from -40 °C to +60 °C. Thanks to its compact dimensions, the sensor can also be integrated into the smallest installation spaces.

Request for a quote

MICRO-EPSILON

Germany

Laser distance sensors optoNCDT ILR103x/LC1 are designed for fast displacement measurement between 0.2 and 15m or rather up to 50m with reflector. The fast response time of 10ms is typical for this series. With buttons at the quite small housing a Teach-In or the assignment of switching points can be done quickly. Tasks of this sensors are fill level measurement, positioning or length measurements.

Request for a quote

MICRO-EPSILON

Germany

The optoNCDT ILR2250-100 laser distance sensor is designed for precise distance measurements in industrial environments. A reflector attached to the measuring object enables distance measurements up to 150 m. Without reflector, the sensor detects measuring ranges up to 100 m. The integrated AUTO measurement mode enables reliable measurements even on dark, partly reflecting and remote measuring objects. Therefore, the ILR2250 sensors can be used for distance measurements on numerous surfaces.

Request for a quote

MICRO-EPSILON

Germany

Laser distance sensors are designed for non-contact distance measurements: laser gauges for measuring ranges up to 10m, laser distance sensors for up to 270m. These sensors are used for positioning and type classification in machine building and handling equipment.

Request for a quote

MICRO-EPSILON

Germany

The optoNCDT 1220 is the entry-level model for precise measurements in industrial automation. This compact laser triangulation sensor measures displacement, distance and position with high precision. Based on an excellent price/performance ratio, this sensor is ideally suited to measurement tasks involving a large number of pieces. Therefore, the sensor can be used in all fields of automation technology, e.g., in machine building, 3D printers or robotics.

Request for a quote

SIKO GMBH

Germany

Laser-based distance sensor for large distances Profile LT5000: Compact design Capable of being integrated easily High flexibility owing to invertible analog characteristic (QA) and switching window function (Q) Easy commissioning and operation via external teach-in Well visble laser light spot of laser class 1 for precise orientation and full eye safety Analog output 0 … 10 V or 4 … 20 mA Measuring range up to 5000 mm

Request for a quote

QUELLTECH GMBH

Germany

Wear is a damage consisting in gradual removal or deformation of material on solid surfaces, caused by mechanical (e.g. erosion) or chemical (e.g. corrosion) influences. In machine elements, wear may give rise to material failure or loss of functionality. For the application in question, our client has to measure wear on the surface of rollers in cement mills. Up from a certain depth, reactions are required, generated by a warning system to be developed In this project, we used several robust QuellTech Q6 scanners to cover fully the roller width. Due to the high rotational speed of the rollers, we preferred our fastest scanners for this application. We furthermore developed a software solution and implemented a warning system, based on the critical depth of the wears on the surface. By means of this system, the customer can determine the correct time for exchange of the rollers.

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

MSO MESSTECHNIK UND ORTUNG GMBH

Germany

Short range Pulse Radar distance sensor

Request for a quote

MSO MESSTECHNIK UND ORTUNG GMBH

Germany

Long range FMCW Radar distance sensor

Request for a quote

EDDYLAB GMBH

Germany

The SL series offers ultimate reliability and precision in a small size, and is designed for industrial and lab use. The sensors can also be used under water because of their high protection class and the stainless steel housing. ■ Measurement ranges 10...600 mm ■ Housing ø20 mm ■ Linearity up to ±0,10 % of full scale ■ Protection class IP67, optional IP68 ■ Sensor working temperature up to 200 °C ■ External, or cable electronics with cable break detection ■ Customized versions available ■ Predestined for use in harsh industrial enviroments

Request for a quote

EDDYLAB GMBH

Germany

The eddy current sensor series IC with integrated electronics guarantees highly accurate measurements thanks to linearized characteristic curve. Accuracy has been improved by up to a factor of 20 compared to previous models. The teach-in function allows the measuring range of the eddy current sensor to be optimally adapted to the respective application. Installation tolerances or material properties of the measured object can be compensated directly. Setting individual measuring range limits offers the user the greatest possible flexibility and simplifies sensor integration. As the complete analysis electronics are built into the sensor, installation and mounting are also extremely uncomplicated.

Request for a quote

EDDYLAB GMBH

Germany

High-quality eddy current probes: Beside robustness, high dynamics and high resolution the TX-Series also stands out with a wide temperature range from -60 °C up to 180 °C. ■ High precision measurement ■ High resolution (submicrometer) ■ High dynamics (124 kSa/s) ■ Minimal temperature coefficient ■ High noise immunity ■ Custom-made probes

Request for a quote

EDDYLAB GMBH

Germany

The CM-Sensors are specially designed for demanding applications: They withstand high pressures up to 100 bars (and more) at temperatures up to 190 °C. At conventional sensors with a similar size the probe head must be kept free from surrounding conductive objects, in order to avoid pre-attenuation of the measuring system. In contrast, the socket for the CM-sensor does not require additional notches or holes.This feature arises from the utilization of zirconium oxide as housing material and ferritic components with a focusing effect. The CM-sensor is typically applied to monitor the orbit of a turbocharger’s shaft.Its ball bearings have a squeeze film damper to reduce the rotor vibration. In order to optimize the entire system the CM-sensors detect the exact position of the turbine- and compressor wheel under real operating conditions.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Screwed onto the internal sensor of the SDT ultrasonic sensors, this accessory significantly increases the sensitivity of the sensor and thus facilitates the detection of ultrasound at a distance of 50 feet /15 meters, maintaining the required level of accuracy.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Rectangular case in anodised aluminium - Shaft in stainless steel - Shaft entry either with floating guidence against dust (AF) or with lip seal (AG) to protection grade IP 65 - Conductive plastic resistance elements - Precious metal wipers - Axial connector or axial or radial cable exit - Ball joints at shaft end and / or case on request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GARMO INSTRUMENTS, SL

Spain

GarLine seam tracking optical laser sensors for automated welding are designed to ensure an easy installation and use on welding robots (cobots and robots with PLC) and on specialised welding machines. GarLine laser sensors have a tough design, with smart electronics, and also offer an easy connectivity and implementation thanks to the decreased need in connection cables and sensor's integrated web server with multiple seam and welding configuration options.

Request for a quote

IPF ELECTRONIC GMBH

Germany

Optical sensors function contactlessly. They detect objects independent of their characteristics (e.g., shape, color, surface structure, material). The basic operating principle is based on the transmission and reception of light. There are three different versions: 1. The through-beam sensor consists of two separate devices, a transmitter and a receiver that are aligned with one another. If the light beam between the two devices is interrupted, the switching output integrated in the receiver changes its status. 2. With the retro-reflective sensor, the transmitter and receiver are located in one device. The emitted light beam is reflected back to the receiver by a reflector that is to be mounted opposite the device. As soon as the light beam is interrupted, the switching output integrated in the device changes its status. 3. With the diffuse reflection sensor, the transmitter and receiver are in one device. The emitted light beam is reflected by the object that is to be detected.

Request for a quoteResults for

Laser distance sensors - Import exportNumber of results

20 ProductsCountries

Company type