- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- knurling inserts

Results for

Knurling inserts - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

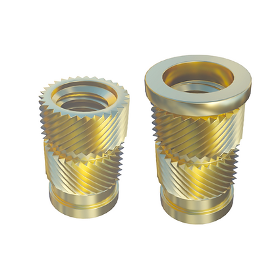

The HEAT-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics Designed for installation in notch-sensitive amorphous thermoplastic materials. The rounded knurling reduces stress on the contact surface while avoiding stress on the material in which it is inserted Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet They are available in unheaded and headed (flanged) versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. Also a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications Unheaded inserts in addition are symmetrical so they do not need to be oriented during installation process

Request for a quote

SPIROL

Germany

SPIROL's KP300 Helical Knurled Pins have helical knurls that span the full length of the pin. The 30° helical knurls cause the pin to rotate during installation into the hole. Helical Knurled Pins offer higher insertion and retention than Straight Knurled Pins. However, KP300 Helical Knurled Pins are not typically recommended when the pin will be subjected to rotational forces as the helical knurl will cause the pin to either "unscrew" itself from the hole or further imbed itself into the hole. KP300 Helical Knurled Pins are available in metric diameters ranging from 2mm to 6mm and in inch diameters ranging from .078" (5/64) to .250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

Press-In Inserts are designed to be pressed into a straight hole without melting the plastic prior to installation. Ideal for use in softer plastics, the helical knurls of the Press-In Inserts are used to provide both torque and pull-out resistance and to ensure good plastic flow as the Insert rotates into the hole. Installation torque to achieve sufficient tension between the threads is not a problem in that the helical knurls are designed so that the direction of the installation torque will have the tendency to drive the Insert into the hole — which of course is not possible — as the threaded joint is tightened. A pilot only slightly smaller than the hole and of sufficient length is designed to assure straight insertion into the hole. Press-In Inserts offer rapid installation with no specialized equipment and achieve good overall joint performance. If installation equipment is required, SPIROL also offers a standard comprehensive line of Insert Installation Equipment.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The EXPANSION-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoset plastics Due to its diamond knurled design, this insert penetrates for a minimum length within the hole walls without decreasing tensile strength. This feature makes it ideal for applications in hard thermoset plastics They are recomended for applications where high resistance values are not required They are installed by simple pressure, without the need for special equipment Headed (flanged) and reverse-headed (reverse flanged) versions are also available. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. In inverted flange inserts, a screw can be inserted on the opposite side of the flange, offeing very high pull-out resistance Also known as BANC-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The SONIC-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics They are designed for quick and economical installation Opposing knurls of the insert offer high torque and pull out performance Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Also known as SONIC-LOK, with equivalent shape, features and dimensions

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

As a general rule, aluminium inserts are mainly used for joining plastics. They are used to stiffen components (tube supports) or as the counterpart to a direct fastening. With the appropriate choice of geometry and alloy they obtain outstanding fastening results. The benefits of aluminium inserts as metal-metal fastenings become evident, particularly for components that are subject to vibration stress or where operating temperatures are high. lightweight flexible durable stable environmentally friendly corrosion resistant The benefits of a trilobular cross-section approx. 35 % greater torsional torques compared with round-knurled inserts greater vibration resistance permits greater core hole tolerances when press-fitting

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Knurling inserts - Import exportNumber of results

6 ProductsCountries

Company type