- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- jets

Results for

Jets - Import export

PAUL LEIBINGER GMBH & CO. KG

Germany

The JET One prints on plastic, glass, wood, metal, ceramic, technical composites, cardboard and paper, without contact, and with fixed and variable data: such as use-by dates, LOT/batch numbers or even graphics. From every position and in every direction. Forward, backward, mirrored or rotated. Even different product surfaces – whether convex, concave, rough, smooth, flat or relief-molded – pose no challenge at all for the JET One. Equipped with the automatic SEALTRONIC nozzle sealing system, the JET One is ready to print in just a few seconds and always begins with a clean print image. This unique technology worldwide ensures 100% protection against ink drying out – even after prolonged downtime. Time-consuming and labor-intensive rinsing cycles and daily servicing are eliminated. And printer-related production losses are a thing of the past.

Request for a quote

LLC RESOURCE TRADING

Russia

1.QUANTITY: 2.000.000 BBLS FOR FIRST MONTH 2.MAX: 5.000.000. BBLS CONTRACT X 12 MONTHS WITH POSSIBLE ROLLS AND EXTENSION 3.ORIGIN: AZERBAIJAN 4.PRICE FOB: $82.00 GROSS / $78.00 NET PER BBLS 5.COMMISSION: $4.00USD PER BBLS TO BE SHARED $2 Seller Side /$2 Buyer Side

Request for a quote

ROBINSON CO.

Turkey

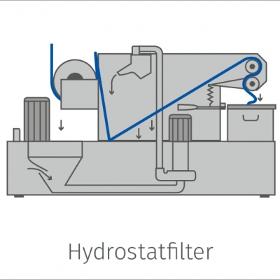

Jet filter cleans the air dust mixture from dust, keeps the dust and ensures that the clean air is discharged from the chimney. The circular filter body first performs the cyclone system purification, and ensures that all dust particles are retained through the bags. It is used to separate the particles in the air used for aspiration and transport in flour mills from the air. Air containing dust and flour enters the machine and this dust sticks to the filter bags in the machine. First purification is carried out thanks to the centrifugal power generated in the round filter body. These filter bags are whipped with compressed air and the dust goes down to the bottom of the filter. Blower or compressor is used for this cleaning process. A bottom scraper or rotoflow is used for throwing these dusts accumulated under the machine. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Cora®Jet is a water jet bonded polyester fleece. It is characterized by a very uniform fibre structure. The large material thickness also supports the deposition of the particles in the depth of the filter medium.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Jet ski’s available at best market prices

Request for a quote

AIR TIME CRITICAL

France

Are you planning to travel back and forth through France or Europe, alone or as a group? Private flight – Save time with a jet plane by flying direct and on your own schedule.

Request for a quote

DRAGFLOW SRL

Italy

For clayey materials, as an alternative or in addition to the disruptor, it is possible to consider a system of high pressure water jets called the jet-ring system. This system consists of a ring, applied in correspondence with the filter of the dredging unit and a centrifugal pump for feeding the ring with a horizontal axis (available in electric and hydraulic version).

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

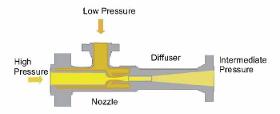

Water jet ejector uses water as motive force. Liquid Jet Eductors use the kinetic energy of a motive liquid to entrain another liquid,completely mix the two, and then discharge the mixture against a counter pressure and are used in large numbers throughout industry for pumping and mixing operations. Water Jet Eductors consist of three basic components, namely a converging nozzle, a diffuser (or venturi), and a body to hold these parts in their relative positions and to provide a suction (or mixing) chamber. In addition, they can be equipped with accessories such as regulating spindles. Water Jet Eductors can also be staged with higher vacuum steam ejectors. In this case, the eductor serves both as the final pumping stage as well as a fairly good direct contact condenser, condensing the motive steam from the high vacuum steam ejectors.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quote

KALOPI PEDICURE SPA

Taiwan R.O.C.

Magnetic pipefree jet with DC24V brushless motor that brings sanitary to a cleanest level.

Request for a quote

MARXAM PROJECT

Poland

Water jet cutting services allow to ensure high quality of the machined surface for details with large thicknesses and complex geometric shapes (high density of cutting lines on a small area, small diameters of holes – of even 1mm). The use of aqua cutting with high pressure, containing fine abrasives, allows to achieve new production effects, which were impossible or time-consuming and expensive using other methods. Using this method, we can process, materials such as: - Ceramic materials - Glass - Plastics - Titanium and its alloys - Materials sensitive to high processing temperatures - Structural, alloy and tool steels (of any degree of hardening) - Cast iron, steel - Copper, brasses, bronzes - Molybdenum and its alloys - Wood and wood-based materials Waterjet cutting technology is one of the most environmentally friendly processing methods. The abrasives used are of natural origin and are chemically inert, and the process itself does not generate any harmful waste.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Jets - Import exportNumber of results

263 ProductsCountries

Company type

Category

- Shearing - steels and metals (48)

- Ink jet printing (28)

- Steam turbines (12)

- Hotels, bars, cafés and restaurants - machinery and equipment (9)

- Nozzles - ferrous metal (8)

- Surface treatment - machinery and equipment (8)

- Electric and electronic components - machines for manufacturing (7)

- Flow meters (7)

- Flowmeters (6)

- Aluminium alloys (5)

- Cutting - machine tools (5)

- Bags (4)

- Cutting - steels and metals (4)

- Fuels, diesel (4)

- Fuels, liquid (4)

- Pumps (4)

- Ventilators and fans - industrial (4)

- Printing - supplies (3)

- Shearing machine tools (3)

- Supply meters (3)