- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water process

Results for

Water process - Import export

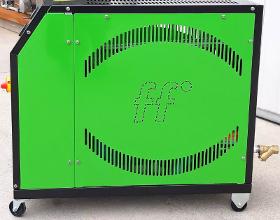

FRIGOFLUID S.R.L.

Italy

Liquid chillers for low temperatures, also in outdoor environments The RW CW series of process fluid coolers (water, water/antifreeze) are water-cooled and operate with environmentally friendly gas compression. They allow cooled liquid temperatures between -8°C and +20°C. In standard design, ambient temperatures of up to +40°C are permissible, but in the “RW ax/HTA” version even higher ambient temperatures can be achieved. IP54 degree of protection as standard, allowing outdoor installation without a protective roof.

Request for a quote

FRIGOFLUID S.R.L.

Italy

ERW ax systems for industrial refrigeration of process fluids (water, water and glycol) are air-cooled units, using EC (Electronic Control) axial fans. This range includes a series of models with cooling capacities from 2.1 kWf up to 595 kWf. Three different versions are provided for different outlet fluid temperature ranges, agreed with the customer during the design phase. The entire range uses refrigerant with GWP 631.

Request for a quote

FRIGOFLUID S.R.L.

Italy

RW ax systems for industrial refrigeration of process fluids (water, water and glycol) are air-cooled: the only resource used is therefore electrical energy, a decisive advantage in contexts where it is advisable to save water (because of its cost or scarcity). The IP54-grade machine protection (against dust and other agents) facilitates their installation in outdoor environments, which is also possible at temperatures up to +40°C and above, at the customer’s request. RW ax liquid chillers from Frigofluid are suitable for achieving average fluid outlet temperatures (between +1°C and 20°C), with excellent control of the resources used for their operation.

Request for a quote

MITA COOLING TECHNOLOGIES

Italy

MITA offers different configurations of air-cooled or water-cooled industrial process chillers: all equipped with electronic microprocessor for setting and displaying the outlet liquid temperatures and all suitable for Industry 4.0. Some advantages of industrial process chillers. - Autonomous unit, with air condensation. - Maximum reliability and performance proven by strict internal tests. - Customizations and flexibility Up to 80% of energy savings in the versions with free cooling system.

Request for a quote

FRIGOFLUID S.R.L.

Italy

Most industrial process temperature control units work through the pressure exerted on the water of the process utilities: this is convenient in most “standard” cases, given the higher efficiency developed by the system. However, some critical process issues can make this type of operation difficult: this is the case of machines that leak fluids, or with leakage, and that it is not convenient to maintain on the spot. In such cases, it is therefore useful to work with a vacuum temperature control unit, which sucks in utility water. FTT PD water thermoregulators are flexible and effective systems, which can work under either pressure or vacuum depending on the peculiarities of the system. Any fluid losses are therefore minimized during operations. A simplicity of operation is also ensured by the touch-screen panel, also found on other Frigofluid temperature controllers. Models with an increased pump are also available for users characterized by high pressure drops.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERREBI PAPER

Italy

Airlaid cloths, dry paper, size 30x33 cm available in two different grammages: light 55 g/m² or heavy 60 g/m². Why choose dry paper cloths? Because by using air instead of water in the paper production process, you get a thick, absorbent cloth. Airlaid cloths are pleasant to the touch, thick enough and very resistant. The airlaid was created to replace cloth products, offering the hygiene advantage that a disposable product can guarantee. 50 pieces per pack, perforated pack for easy opening.

Request for a quote

FDT SRL DEPURATORI D'ACQUA

Italy

Recently a new deionization technology, the continuous electro-deionization has been developed, which is a combination of electro-dialysis and ion exchange. It is obtained by a process, which deionized water while the resins are continuously regenerated by means of the electric current inside the unit. This electrochemical regeneration replaces the traditional chemical regeneration of ion exchange systems. The electro-deionization module must be supplied with pre-treated water with reverse osmosis: By combining these two techniques is obtained ultrapure water (0.1-0.2 mS / cm), starting from the drinking water.

Request for a quote

FDT SRL DEPURATORI D'ACQUA

Italy

The water demineralizing Plants eliminate all the salts contained in it. Water obtained by this process, meets the needs of hospitals, chemical processing, power plants etc. They are essentially constituted by a heat exchanger containing the cationic resins and a heat exchanger containing the anionic resins. The heat exchangers can be made in: - fiberglass - Ebonized steel - Acid-resistant steel

Request for a quote

PRAGMA BUYING SRLS

Italy

Continuous stainless steel plants for ethanol dehydration by a physical / chemical process called adsorption. In this process water molecules are trapped on the surface of adsorbing solid, called molecular sieve, removing water from the mixture to be dehydrated. During the adsorption process molecular sieves tend to become saturated, that means, in order to restore their dehydration capabilities, after the absorption phase a regenerative one must be carried out.

Request for a quoteResults for

Water process - Import exportNumber of results

10 ProductsCountries

Company type

Category

- Refrigeration plants and equipment, commercial and industrial (4)

- Water purification (2)

- Filtering equipment and supplies (1)

- Water treatment, industrial - systems and equipment (1)

- Disinfection and sterilisation services (1)

- Measurement and regulation equipment and instruments - temperature (1)

- Paper, self-copy (1)

- Pharmaceutical industry - machinery and equipment (1)