- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining

Results for

Machining - Import export

FERPLAST SNC

Italy

Semiautomatic impulse heat sealers for the bench, for closing PE, PP, PVC and light coupled bags. Equipped with timer, pedal and trimmer. They can be used for: food products, in the automotive, cosmetics, electronics, mechanical and plastic parts, packaging for e-commerce, pellets and agriculture and for chemical products. Available in 460mm and 610mm welding lengths, and 4mm high. Suitable for bags of different thickness, with moist or dusty contents. Double sealing bar with separate regulation of temperatures and times. Manual and semi-automatic operation with electromagnetic closure. Adjustment of the welding power by means of a 6-position switch. Activation by electric pedal or automatic cycle button with digital control of the welding parameters. Digital timer with LCD, for precise control of welding (0-10 sec.) And cooling (0-20 sec.) Times. Can be combined with dosing systems.

Request for a quote

FERPLAST SNC

Italy

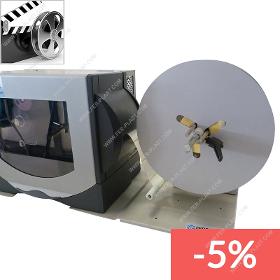

FP-UWR is a series of self-adhesive roll-out labels in rolls built for industrial use, robust, completely made of steel, equipped with a large support base for a stable connection to the printer. Available in versions with a maximum width of 130 mm. or 230 mm. The expansion mandrel allows the use of internal cores from 40 to 110 mm. (76 mm for the BIG model) and rewind reels up to an external diameter of 300 mm (400 mm for the BIG model). An innovative system for detecting the position of the dancer allows to perfectly follow the speed of the printer avoiding tears or continuous stops. It is possible to rewind in a clockwise or counter-clockwise direction and select the maximum speed range to be reached. Powered at 230V or on request 115V, it does not require a separate power supply. The microprocessor control board also allows to stop the rotation of the motor when the reel is finished or in case of paper breakage, signaling the anomaly with an audible signal.

Request for a quote

FERPLAST SNC

Italy

RTR is an unwinder and rewinder rolls of self-adhesive labels. The microprocessor card of control also allows to stop the rotation of the motor coil is completed, or in case of paper breakage signaling the anomaly with a sound signal. Easy to use, robust, completely made of steel, with a large base of support. Available in widths 140mm or 230mm. The spindle enables the use of internal cores 46 to 110 mm and rewind reels up to an outside diameter of 300 mm. It's possible to play and rewind clockwise or counter-clockwise and select the maximum speed range to which you want to get. Powered by 230V. It does not require a separate power supply.

Request for a quote

FERPLAST SNC

Italy

Manual eyeleting machine suited to the insertion of the eyelets on boxes of pasta, biscuits and food in general. The eyelet is very used to attach the jumper on which are printed all product-related information.

Request for a quote

FERPLAST SNC

Italy

The TRITONE labeller was made by dividing it into modules, so as to allow use in both horizontal and vertical positions and easy integration into the packaging lines. The control is entrusted to a microprocessor, which manages the pre-separation in mm. and regulates the speed from 0 to 30 mt. min. TECHNICAL FEATURES Stepper motor with variable speed from 5 to 30 mt./min. Maximum label width mm. 100 Minimum label width mm. 20 Maximum label length mm. 300 (higher on request) Minimum label length mm. 20 Label application delay via electronic setting Label application precision mm. 0.5 Label reel with internal diameter mm. 40-76, external mm. 300 max Rewinding roller for silicon paper recovery Variable reading photocell for label stop REFLEX photocell for product detection End of roll alarm (optional) Electronic control unit Switch Stroke counter with zero setting Protection fuses Potentiometer for speed adjustment of labeling head Power supply 220 V 50 Hz. Dimensions mm.

Request for a quote

FERPLAST SNC

Italy

D-FPWR BOTTLES - SEMI-AUTOMATIC LABELING MACHINES FOR ROUND PRODUCTS Semi-automatic applicator for rolls of self-adhesive labels with maximum width mm 200/300 on bottles and cylindrical products with a diameter of mm 20 to mm 130 Main features: - Sturdy construction in steel and aluminum - Motorization of the product rotation roller and the drawing of the labels by means of stepper motors with variable speed and electronically synchronized - Microprocessor management electronics with storage of 40 working formats - Possibility to apply a wraparound label or front/back label and also with a different size with adjustment of the distance between the two programs - Maximum label width mm 200/300, and maximum coil diameter 300 mm - Change of format extremely simple and fast

Request for a quote

FERPLAST SNC

Italy

DFP-WR is a series of semi-automatic distributors of adhesive labels on rolls, completely made of steel, easy to use, versatile for any type of label you normally use. Available in widths up to 100 mm. or 200 mm. The holder can be adapted to any core can accept rolls up to 300 mm. diameter, thus offering long autonomy.The labels are read by two sensors that self-learning by the microprocessor automatically identify the difference in transparency between the label and the backing paper, presenting the label on the peeler, almost completely detached. Withdrawing the label, the next pop-up automatically. The control board also allows you to stop the rotation of the motor when coil is finished, or in case of paper breaking. It sign the anomaly with a sound signal. There is an electromechanical sensor for transparent labels and a preset counter for the regressive or progressive counting of the labels. The use of the battery version allows to work for about 4 hours without power supply.

Request for a quote

FERPLAST SNC

Italy

The labels are read by two sensors that, self-learning by the microprocessor, automatically identify the difference in transparency between the label and the backing paper, presenting the label on the peeler almost completely detached. Withdrawing the label the next pop-up automatically. The control board also allows to stop the rotation of the motor coil is completed, or in case of breakage paper signaling the anomaly with a sound signal.

Request for a quote

FERPLAST SNC

Italy

FP CHECK is a machine suitable for the treatment of self-adhesive labels in reel allows you to: - To rewind clockwise or counterclockwise on different spindle diameters - Count the labels through a progressive or regressive contactor - Check the presence of the labels and stop in the presence of a missing label Working as a rewinder allows you to rewind labels from rolls with max. diameter of 300 mm, wrapped internally or externally, with a core diameter ranging from 46 mm to 110 mm, to rolls with max. diameter of 300 mm wrapped internally or externally. The average speed of rewinding is more than 50 meters / minute. In the control function, a photocell allows in addition to counting of the labels, to check the presence of the labels and indicate its absence with the possibility of stopping for repositioning. The operation takes place without any setting but via the control unit that self-learns the label length. For transparent labels there is a ultrasound photocell.

Request for a quote

FERPLAST SNC

Italy

FP RWR is a series of reel-winders of self-adhesive labels in rolls built for industrial use, robust, completely made of steel, equipped with a large support base for a stable connection to the printer. Available in versions with a maximum width of 130 mm. or 230 mm. The expansion mandrel allows the use of internal cores from 40 to 110 mm. (76 mm for the BIG model) and rewind reels up to an external diameter of 300 mm (400 mm for the BIG model). An innovative dancer position detection system allows to perfectly follow the speed of the printer avoiding tears or continuous stops. It is possible to rewind in a clockwise or counter-clockwise direction and select the maximum speed range to be reached. Powered at 230V or on request 115V, it does not require a separate power supply. The microprocessor control board also allows to stop the rotation of the motor when the reel is finished or in case of paper breakage, signaling the anomaly with an audible signal.

Request for a quote

FERPLAST SNC

Italy

MANUAL DISTRIBUTORS OF LABELS MOD. TOWA AP 65 Manual dispenser for pre-printed labels on rolls. Fast and precise on flat and curved surfaces. The patented Mecha-sensor system automatically adjusts the application pitch according to the length of the labels. Each time the lever is operated, the label advances by max. 60 mm., If the label is longer, several drives are required.

Request for a quote

FERPLAST SNC

Italy

Pneumatic eyeletting with dual head with automatic feeder, suitable for any process where it is required the simultaneous closing of the two eyelets, complete with support frame and security guards. The eyeletting is applied in the paper industries, offices bank or post office, anywhere where there is a need to securely seal their products but use is higher in the food industry for sealing and the simultaneous application of cards printed on plastic bags.

Request for a quote

FERPLAST SNC

Italy

Eyeleting with mechanical pedal, double head with automatic feeder and support frame, suitable for any process where it is required the simultaneous closing of the two eyelets. The eyeletting is applied in the paper converting industries, offices bank or post office, anywhere where there is a need to securely seal their products but use is higher in the food industry for sealing and the simultaneous application of cards printed on plastic bags.

Request for a quote

FERPLAST SNC

Italy

Mechanical eyeletting machine with single head, automatic feeder, cast-iron frame and stand. Suitable for medium volume applications and where one eyelet are required. Ideal for automatic application of warranty seals in cardboard industry, bank office, post office and in many others field. It is especially used in food industry for to seal and at the same time for to apply a printed card on plastic bags.

Request for a quote

FERPLAST SNC

Italy

Manual eyeleting machine suited to the insertion of the eyelets on boxes of pasta, biscuits and food in general. The eyelet is very used to attach the jumper on which are printed all product-related information.

Request for a quote

FERPLAST SNC

Italy

MANUAL NUMERICAL AND ALPHANUMERIC PRICING MACHINES FP-PRZ2 SERIES with 1 or 2 PRINT LINES FOR LABELS 26x16 mm rectangular and wave shape The manual pricing machines are suitable for printing prices, dates, lots, deadlines and codes on adhesive labels. They are particularly suitable for use in the food sector, where it is necessary to specify batches and expirations of the products and wherever it is necessary to label. The pricing machines produce numerical or alphanumeric writings on one or two printing lines and depending on the model the printable characters can be from 8 to 10 per line. The 26x16 labels are available in wave and rectangular format. The most used are white, however it is also possible to request other colors and pre-printed. The printing lines of the pricing machines can be: - numeric: all numbers with dashes and currency symbols (£/€/$). - alphanumeric: all numbers and letters WITHOUT currency symbols.

Request for a quote

FERPLAST SNC

Italy

MANUAL NUMERICAL AND ALPHANUMERIC PRICING MACHINES FP-PRZ SERIES WITH 1 PRINT LINE FOR LABELS 26x12 mm wave The manual pricing machines are suitable for printing prices, dates, lots, deadlines and codes on adhesive labels. They are particularly suitable for use in the food sector, where it is necessary to specify batches and expirations of the products and wherever it is necessary to label. The pricing machines produce numerical or alphanumeric writings on a print line and depending on the model the printable characters can be 8 or 10. The 26x12 labels are available only in wave form and the most used are white, however it is also possible to request other colors and pre-printed. The characters of the pricing machines can be: - numeric: all numbers with dashes and currency symbols (£/€/$). - alphanumeric: all numbers and letters WITHOUT currency symbols

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TASK ITALY SRL

Italy

Fully automatic machines for applying self-adhesive labels on cylindrical and conical bottles and jars. Extremely versatile and easy to use, suitable for various industries, from beverage bottling to packaging of food, cosmetics, pharmaceutical, and chemical products. Available with a wide range of customizations, including: - Capability to install from 1 to 3 labeling groups - 360° wrap-around labeling - Application of seal labels on jars - Centering of existing marks, logos, labels - Integration of dispenser and capsule closing head for the wine and olive oil sectors - Printing of batch, expiry date, and other markings - Adaptations for labeling square and conical bottles - Adaptations for small-sized bottles and jars (miniatures, single-dose) - Tables and collection plates for labeled products Production: Approximately 1,000 pieces/hour.

Request for a quote

TASK ITALY SRL

Italy

Automatic self-adhesive labelers are designed for labeling bottles, flasks, jars, and other cylindrical and shaped containers. The series of self-adhesive labelers are available in different models with 3, 6, 10, or 12 plates arranged on a central carousel. Moreover, they can be equipped with one up to five labeling groups to meet various application needs and production speeds. Further customization options include different available features (touch-screen programming controller, hot printer, bottle accumulation tables). All labeling groups come with dedicated electronic boards and can be fitted with special sensors for applying transparent labels. Production: 2,000 - 12,000 B/H (bottles per hour).

Request for a quote

TASK ITALY SRL

Italy

Machine for distributing and smoothing sparkling wine capsules and applying body label, back label, and neck label on cylindrical glass bottles from 187ml to 150cl. The monobloc's production capacity is 800 b/h with complete packaging for sparkling wine, whereas for wine bottles with label and back label, it can reach up to 1,800 b/h. Features include: automatic distributor for the sparkling wine capsule with an inclined loading platform, double optical alignment of the capsule with the brand, pre-smoothing head for inserting the capsule and smoothing using a double pneumatic head, 3 self-adhesive stations driven by stepper motors, electronic board for label start signal, electronic adjustment of label positioning via a touch-screen display, speed adjustment via inverter, full stainless steel safety protections, selection auger for 75cl cylindrical glass bottle format, pulling head, and rectangular bottle collection plate.

Request for a quote

TASK ITALY SRL

Italy

Benchtop labeler for applying self-adhesive labels from a roll. Capable of applying body labels (including 360° wrap-around) and back labels (on the same roll as the body label). Benchtop machine with manual cycle start. The machine enables labeling of bottles, jars, cylindrical glass, or plastic containers. Description and operation: The operator must individually place the containers vertically on the platform; pressing a start button initiates the labeling cycle. The spacing between the label and the back label is easily adjustable via a graduated scale potentiometer. All other working parameters are adjustable through a keypad with a display. An ink printing device (optional) allows for stamping an expiration date or a lot number. Available versions: 1 or 2 stations for cylindrical bottles, 1 station for square bottles. Production: 700-800 bottles/hour.

Request for a quote

GABELLA MACCHINE SPA

Italy

Cut-to-length lines for T-shaped panels Slitting and recoiling lines with automatic separators positioning Dedicated plants for pre-painted,? film-coated or other special materials (stucco-design, mesh, ground surfaces…) Special lines for panels production, with punching, shearing, roll-forming and bending Continuous punching lines Spool recoiling lines De-burring lines Combined lines with partial cut, where a part of the strip is recoiled for future use Machines for mass production or very flexible plants for small productions Cut-to-length and recoiling lines, with coils packaging stations. Customized and very enhanced productions, which integrate the sheet-metal processing with rotating turret punching (possibility of up to 24 different tools? a time, even in “multitools” solutions) or fiber laser cut.

Request for a quote

GABELLA MACCHINE SPA

Italy

Here are the latest news from our Research and Development department. Our customers always care about the minimum detail and try to optimize as much as possible costs and time. Here are some of the latest products developed thanks to them and together with them: Automatic solutions to reduce the number of operators on a line, for instance: AUTOMATICALLY POSITIONED SEPARATORS, for recoiling lines provided of automatic N.C. slitter. They move together with the slitting heads, exploiting the same concept. So, they have the same advantages: the operators are free for other tasks, it is possible to memorize recipes. Special products and needs, for instance:

Request for a quote

GABELLA MACCHINE SPA

Italy

Combined cut-to-length and recoiling lines, that decoil, straighten, cut and recoil various kinds of sheet metal. They are suitable for coils of sheet-metal of any kind and with max thickness 4 mm. The results are parcels of blanks that can be piled-up with a stacker and recoiled strips of different widths, even obtained by partial cut. Our plants are provided of remote assistance equipment, to guarantee precise and immediate interventions, to modify the software parameters and quickly solve emergencies and stops of the machines.

Request for a quote

GABELLA MACCHINE SPA

Italy

Each line is carefully designed on the customers indications, starting from a general structure that is as follows: Coil car, motorized and with hydraulic lifting Decoiler, designed on demand and with the required capacity (up to 30 ton) Straightening group with one of the different precision straighteners or levellers we can propose. We have in our range also “cassette-system” levellers, for the quick exchange of the working rolls. They are particularly useful for those who have a big range of materials and thicknesses. Guillotine shear (start-stop or non-stop models) or flying shear. This last one allows the flying cut of the sheet-metal, without stopping or slowing down the passage of the material. The shear moves synchronized with the metal strip. The control equipment checks the material movement and automatically decides, according to the speed, to move the car that holds the shear.

Request for a quote

GABELLA MACCHINE SPA

Italy

It is a special slitter with Numerical Control, different from all the others available on the market, with a variable number of slitting heads, which include in one single body the upper and lower blades. This allows to easily adjust the clearance between the blades (now also automatically) and to reduce the wearing. The characteristic that makes this slitting group original and extremely efficient is the system of changing the slitting widths, without manual intervention of the operator. The slitter can be managed by N.C., so from the line control-board, by remote control, or even by a PC interfaced to our customized softwares: GA.GE. or GMDesign.

Request for a quote

GABELLA MACCHINE SPA

Italy

It can be completed by many options (scrap-coilers or scrap-choppers, film or protective paper applicators…) and with devices to help the coils loading and unloading: coils cars, rotating arms, rotating tables for the automatic strapping, magnetic lifting systems, conveyors and so on… They are all studied together with the customers, following his needs and preferences.

Request for a quote

CARONI S.P.A.

Italy

You never forget your roots. When it was first founded in 1954, the company’s focus was mechanical machining: even today it maintains an obsession with the perfection of detail and craftsman-like care, though numerical control machinery is now used alongside conventional machines. Mechanical chip removal is performed with the aid of milling machines, CNC lathes and machining units, grinders, punching machines, broaching machines, boring machines, tapping machines, etc. The machines work with materials such as spheroidal cast iron, steel, aluminum and sheet metal assemblies.

Request for a quoteResults for

Machining - Import exportNumber of results

29 ProductsCountries

Company type