- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling

Results for

Filling - Import export

FERPLAST SNC

Italy

The idle roller with boxes-stopper plan allows the operator to "lock" the box still to be closed and make the filling operations. Depending on customer requirements can be matched more filling stations. For safer packaging, especially of fragile goods such as glasses, bottles and cosmetics, it is also possible to place beside the operator a machine to create air cushions.

Request for a quote

FERPLAST SNC

Italy

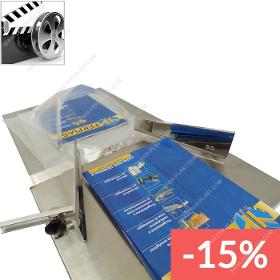

Semi-automatic line consisting of taping machine FP9036 with side straps (or FP9037 with straps above and below) for closing the upper and lower flap of the box and special plan for loading products. To facilitate the packaging operation of the products, an idle conveyor roller with boxes-stopper plan has been positioned before the taping machine. In this way it is possible to block and fill securely, quickly and easily the box not yet taped simply taking the products from a plan or from an adjacent container. Then, with a simple push, the operator will move the box in the taping machine.

Request for a quote

FERPLAST SNC

Italy

FPXBAG-NEW is an innovative semiautomatic vertical packaging machine which combines different existing technologies with unique innovations. FPXBAG-NEW is an easy to use, economical and functional form-fill-seal machine which creates 3 hermetic sealing bags starting from a plain foil roll. Compared to the other vertical machines, FPXBAG-NEW has an innovative system of forming box which allows to get a fast format change. This systems reduces the machine shot-down and we gain in productivity. Moreover the two clamps of the horizontal sealing allow to keep the forming bag in position reducing the any break possibility. The key factor of the FPXBAG-NEW is the versatility of the machine which can seal any kind of film, this thanks to the incomparable sealing system. The machine is supplied with 1 forming tube type 200 (suitable for making bags with a width of 185 mm). On request it is possible to have forming tubes with different sizes, type 200 and type 250.

Request for a quote

FERPLAST SNC

Italy

Suitable for all types of neutral or printed film (preferably with antistatic treatment) or tubular polyethylene with thickness from 0.06 mm to 0.13 mm or tubular polypropylene with from 0.03 mm to 0.05 mm thick, and cartene normal or high density. Furthermore, with the FP BAG EVO it is also possible to use expanded polyethylene (FOAM) in tubular reel with a maximum thickness of 1.5 mm. It can use reels with a width of 80-300 or 100-500 mm without disassembly of parts or changing settings. The packaging machine automatically perform the forming of the bag with the upper opening. The filling of the bag and the subsequent closing can be done manually by an operator who starts the cycle of the machine through a button, or automatically by means of feeders, manipulators, weighers. The reel change takes a maximum of thirty seconds. The machine cycle time for the preparation of a bag 200 mm long is about four seconds.

Request for a quote

FERPLAST SNC

Italy

The PANDYNO FPPD vertical inserters allow to an operator to fill and seal the packs avoiding the use of preformed bags. The operator must in fact insert the product to be packaged in the magazine tube, on which a few meters of tubular film have been previously loaded. The product goes down into the tubular film up to the support surface. The operator manually closes the sealing bar by applying a slight pressure on the bar. The welding machine in a single operation carries out the welding of the package, the cutting of the film and the welding of the bottom of the next envelope. This operation takes place using an electromagnetic blocking device. By equipping the bagging machine with several loaders, it is possible to increase the productivity of the machine. To avoid waiting times it is also possible to pre-load different magazine tubes so that they can be quickly replaced once the film is finished. The standard model can be placed on a bench and comes with a charger of your choice.

Request for a quote

FERPLAST SNC

Italy

BAG OPENER - BAGS OPENING DEVICE The Bag Opener is an opening device characterized by a regular and silent motorized fan and is designed to quickly pack and fill the bags. It consists of a stainless steel body suitable for contact with food and easy to clean. The bags with a hole for hooking are very easy to change and the constant air flow opens them easily one after the other. Fan with two-speed motor and on/off switch. Adjustable guides to facilitate filling. Attention: the collection of the bags takes place by tearing (naturally a small piece of bag will remain torn off).

Request for a quote

TASK ITALY SRL

Italy

Operation: The vacuum draws the product from the storage tank into the bottle without any contact between the product and other mechanical components of the machine. Features: • Automatic product level in the bottle with manual adjustment. • Stainless steel base, structure, and nozzles. • Gaskets and other plastic components made from materials certified for food use. • Height adjustment for different bottle sizes with centralized spring. • Vacuum adjustment based on the product type with a pressure gauge. • Filter to protect the pump group. • Borosilicate glass product recovery tank. • Universal product transfer tubes (suitable for wines, beer, oil, spirits, hot fruit juices). • Completely accessible and sanitizable product transfer circuit. • Availability of special nozzles for filling small mignon bottles. Ultrafill-2 Model: from 200 to 400 bottles per hour. Ultrafill-4 Model: from 400 to 600 bottles per hour.

Request for a quote

TASK ITALY SRL

Italy

The semi-automatic capper model 'TSP' is suitable for applying aluminum (or plastic) screw caps to glass bottles. This semi-automatic machine is made of stainless steel and features a pneumatic bottle lifting system. The caps are manually placed on the bottle, while the operation cycle is activated with 2 buttons on the side of the machine. The machine operates electrically with a contactor and CE-compliant safety guards. After the cap is threaded and sealed, the platen automatically descends, allowing the removal of the capped bottle and replacing it with another to be closed. The capping head has 4 stainless steel rollers and comes with a No-Cap No-Roll safety device, suitable for all types of closures, including Stelvin 30x60 caps. It is suitable for all standard bottle sizes ranging from 25cl to 150cl. A magnetic friction head is available for pre-threaded plastic caps or twist-off caps. Production capacity: approximately 600 bottles per hour.

Request for a quote

TASK ITALY SRL

Italy

These cappers are designed for closing aluminum or plastic screw caps, or crown caps, on cylindrical or shaped bottles. Caps feeding is done using a centrifugal, rotary, or vibratory feeder, and the transfer of the caps is achieved through a descending channel that ends with the distribution head. The stainless steel threading heads with 4 rollers (with 'no cap/no roll' device) allow for excellent threading and capping of a wide range of caps. Standard features include: - Centrifugal Feeder - Inverter for speed adjustment - PLC for cycle control - Production display and anomaly signaling - Bottle height format management from PLC - 2 photocells on the cap descent channel - Photocell for exit accumulation control on the conveyor belt - Inlet selection screw - Safety guards and stainless steel electrical panel - Electric lifting of the capping head Production capacity: from 3,000 to 12,000 bottles per hour.

Request for a quote

TASK ITALY SRL

Italy

The SC-10 rinser, consisting of a rotating table with intermittent movement at 10 positions, allows for the prevention of biological contamination in bottles and jars caused by the presence of dust, leaves, small insects, and the risk of serious incidents due to possible glass fragments inside the containers. It is possible to insert and remove bottles from the front position. The spray of rinse water or sanitizing solution occurs only when the bottle is present, thanks to a contact microswitch. For the use of a recirculating solution, a kit with a recovery tank, pump, and connecting pipes is available. The machine is equipped with a filter for the rinse solution with a 0.45-micron microfiltration cartridge. It is also available in a 20-position version and a blow-only mode. Production: 700 pieces per hour.

Request for a quote

TASK ITALY SRL

Italy

The 'RT-PK' monoblocks are designed for packaging liquid and dense products such as yogurt, probiotics, milk, liquid cream, sauces, syrups, and spreadable creams, into bottles and jars with pre-threaded or snap-on plastic caps. These machines include: -Filling Station, available in single or multi-head configurations. The filling process utilizes a volumetric system with rotary pumps made of AISI 316 stainless steel, controlled by a PLC and inverter. -Bottom filling valves are available as an option. -The caps are picked up from the release head by a pneumatic arm and placed directly onto the bottle, where they are screwed or pressed into place. In addition to or instead of the capping station, the machines can be equipped with a heat-sealing head with one or two heat-sealing punches, used to seal the caps with a film from a reel. Hourly production capacity: from 900 to 2,000 bottles per hour, depending on the machine version and the product.

Request for a quote

TASK ITALY SRL

Italy

Semi-automatic filler for chemical and cosmetic products. It includes: -Frame and metal parts made of AISI 304 stainless steel, with either feet or wheels. -Adjustable height support platform. -'Flow-meter' liter counting group interfaced with a PLC for dosing control. -Product supply through rotary pumps with AISI 304 stainless steel bodies. -Electronic board with a display for setting the dosing and calibrating working parameters. -Manual button or foot pedal for starting the filling cycle and stopping when the set liters are reached. -Potentiometer for flow speed adjustment, with gradual slowdown in the final phase. -Complete electrical panel, including: general on/off switch, start button, voltage presence indicator, manual/automatic selector. -Option for bottom filling with a diving nozzle suitable for foamy products. Hourly production: approximately 200 x 5L containers.

Request for a quote

TASK ITALY SRL

Italy

The automatic single-head cappers are designed to apply aluminum caps or screw-on and snap-on plastic caps to glass or PET bottles. All closure heads are made entirely of stainless steel, as well as most of the machine components. The speed variation is electronic, controlled by an inverter. Other capping systems are available to meet different needs: cork, crown, twist-off. It is also possible to combine 2 turrets on the same machine with different combinations, for example, screw cap + cork, cork + crown, screw cap + T-cork. The range of single-head cappers is designed for productions of up to approximately 2,500 bottles per hour and can be integrated with automatic cap feeding systems of both mechanical and pneumatic types.

Request for a quote

TASK ITALY SRL

Italy

The RTW600 is an automatic linear monoblock filling machine equipped with a distributor-orienter, an adjustable descent channel with a photocell for capsule presence detection, and a double jar stop for distribution and twist-off capsule capping. Hourly production capacity: approximately 800 jars/hour. Main features: -Stainless steel base on adjustable feet (or wheels). -2-meter-long linear conveyor belt with motorized drive and final accumulation plate. -Pneumatic group for container interception and separation. -Volumetric dosing unit suitable for dense liquids such as honey, fruit juices, jams, sauces, pastes, pâtés, dressings, melted cheeses, creams, etc., adjustable from 40 to 1000 cc. -Pneumatic capper with low rotational speed and adjustable torque. The machine does not require a format change for containers of different shapes and sizes, only for capsules with different diameters. Versions for higher productions are also available.

Request for a quote

TASK ITALY SRL

Italy

Isobaric filler for beer and other carbonated products, equipped with 5 filling valves and a bottle selection and transfer system using large-diameter stars. The filling valves are made of stainless steel with heat-sanitizable gaskets. The filling cycle is fully automatic, with an initial valve opening for counter-pressure, full opening for bottle filling, and decompression (degassing). The different phases and processing times are controlled by an electronic controller (PLC), with adjustments available through a touch-screen operator panel. An automatic capper is included for pry-off crown caps with a diameter of 26mm, with automatic cap distribution using a stainless steel hopper. The machine features a central 10-compartment star and bottle guide made of high-density polyethylene, with a safety microswitch. The machine's base is made of AISI 304 stainless steel. The indicative filling capacity with 0.33L bottles is approximately 700 bottles per hour.

Request for a quote

TASK ITALY SRL

Italy

The pneumatic volumetric dosers DV series are used for precise filling of a wide range of food products (creams, sauces, jams, honey, yogurt) or non-aggressive chemical-cosmetic products (creams, lubricants, detergents, liquid soap, shampoo). Made of stainless steel, they come with a tabletop support or an adjustable height support platform and a supporting column. The dosage can be easily adjusted using a handwheel with a graduated reference scale. The pistons can be completely disassembled using clamp clamps for cleaning operations. The dosers are equipped with a foot pedal control for starting the semi-automatic dosing process. A stainless steel hopper with variable capacity depending on the models is provided (for maximum precision, the use of the hopper is recommended). Production: from 3 to 12 doses per minute, depending on the dosing volume.

Request for a quote

TASK ITALY SRL

Italy

Machines designed for packaging liquid or dense food products in jars and bottles, for dosing sauces, gravies, mayonnaise, fruit juices, syrups, purees, yogurt, kefir, and milk. Equipped with dosers featuring rotary pumps made of AISI 304 stainless steel, motorized with electric motors and controlled by inverters. Dosing and rotation speed are adjustable via an electronic pulse counter set through a touch-screen interface. Drip-proof nozzle with a two-way pneumatic valve synchronized with the dosing, pneumatically controlled. Dosing can be adjusted from 20 cc and above. Container movement on a chain with stainless steel or acetalic shutter, synchronized with the container introduction and filling phases. The base model comes with 3 dosers, but versions with 2, 4, 6, or 8 dosing heads can be customized. The standard version does not require format changes. Hourly production: ranging from 500 to 6,000 pieces per hour.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Filling - Import exportNumber of results

17 ProductsCountries

Company type