- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- touch panel

Results for

Touch panel - Import export

FERPLAST SNC

Italy

Wrapping machine with turntable FP ECO/A ROLL for wrapping carriages (roll container), with manual hooking/cutting of the film and automatic wrapping cycle, limit switches adjustable in height to stop reel holder, adjustable limit switches at the base of the reel holder to start wrapping to the desired height, touch panel display with 3 programs winding, truck driving, foot operated mechanical lock, loading ramp for pallet trucks. (Machine CE).

Request for a quote

FERPLAST SNC

Italy

High speed with PLC and Touch screen control panel The new FPWK 0430-TOUCH model represents a remarkable evolution compared to the previous models because it can use polypropylene band with a thickness from 60 my to 150 my and polythene paper band with a thickness from 100 to 130 my. The maximum speed is 30 cycles/min. The machine is equipped with a Schneider Touch screen control panel (simple and intuitive) with which all the functions of the machine can be easily checked with the exception of the tensioning which is adjustable via a separate potentiometer. The standard bench model uses 150 m spools. but the machine can be installed on a motorized reel holder for rolls of 500-1500 m. The FPWK 0430 banding machine in addition to the classic use in graphic arts, bookbinding, paper converting, is particularly suitable for the realization of multiple packs or for the combination of multiple products in promotional sales.

Request for a quote

TASK ITALY SRL

Italy

Isobaric filler for beer and other carbonated products, equipped with 5 filling valves and a bottle selection and transfer system using large-diameter stars. The filling valves are made of stainless steel with heat-sanitizable gaskets. The filling cycle is fully automatic, with an initial valve opening for counter-pressure, full opening for bottle filling, and decompression (degassing). The different phases and processing times are controlled by an electronic controller (PLC), with adjustments available through a touch-screen operator panel. An automatic capper is included for pry-off crown caps with a diameter of 26mm, with automatic cap distribution using a stainless steel hopper. The machine features a central 10-compartment star and bottle guide made of high-density polyethylene, with a safety microswitch. The machine's base is made of AISI 304 stainless steel. The indicative filling capacity with 0.33L bottles is approximately 700 bottles per hour.

Request for a quote

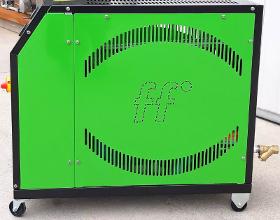

FRIGOFLUID S.R.L.

Italy

Most industrial process temperature control units work through the pressure exerted on the water of the process utilities: this is convenient in most “standard” cases, given the higher efficiency developed by the system. However, some critical process issues can make this type of operation difficult: this is the case of machines that leak fluids, or with leakage, and that it is not convenient to maintain on the spot. In such cases, it is therefore useful to work with a vacuum temperature control unit, which sucks in utility water. FTT PD water thermoregulators are flexible and effective systems, which can work under either pressure or vacuum depending on the peculiarities of the system. Any fluid losses are therefore minimized during operations. A simplicity of operation is also ensured by the touch-screen panel, also found on other Frigofluid temperature controllers. Models with an increased pump are also available for users characterized by high pressure drops.

Request for a quote

M SERVICES SRL

Italy

Our centring-facing machines are designed to meet the request of higher flexibility, precision and simplification of small and large production end-machining , combining great power and high rigidity and also allowing to integrate an automatic loading / unloading system.The base is an electro-welded and normalized steel structure and it has been specially designed with directional slides to convey chips into the specific integrated conveyor; the underlying ribs are arranged in such a way as to be able to absorb any vibration.The use of a touch screen operator panel with easy programming ensures versatility and simplicity of application, making simultaneous machining possible on both ends.Two opposite working units are used, each moved on CN work axes (axis “Z1” and “Z2”) frontal to the piece, whereas the Self-centering clamps with oleodynamic control are moved by a third controlled CNC axis (X axis) for the management of the drilling / centering tool center as well as for millin

Request for a quote

GI.EMME.PI

Italy

The new automatic touch screen unloader can be made in a 1,2,3,4 lane version. Depending on the parts to be bonded, the tracks are tailor-made at the customer's request in terms of width and length. The high resolution photocells are able to read any fabric in any light condition. The machine is operated via by a touch screen panel. The unloader tracks can work in combination or independently. Another great advantage, in addition to the total elimination of unloading operators, is the operation of the only electric discharger system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Touch panel - Import exportNumber of results

6 ProductsCompany type