- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- titanium alloys

Results for

Titanium alloys - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

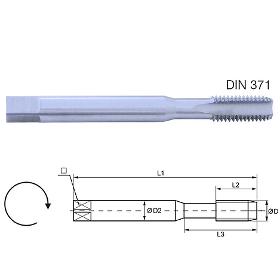

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For titanium Material of product: HSSE Surface treatment: no For materials: Pure Titanium and Titanium alloy Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H The geometrie and base material (HSSK powder metal) is made to cut into titanium and titanium alloy. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Our high-performance cutting paste in the practical 100ml pack is characterised by particularly high pressure additives that achieve a very high lubrication performance. The paste adheres firmly to the cutting edges and only becomes liquid during use. For optimum results, the cutting paste should be applied undiluted. This cutting paste is ideal for many machining operations such as drilling, thread cutting, thread cutting, milling, core drilling and sawing. It is suitable for all types of steel - from iron and tool steel to high-alloy steels and chrome-nickel alloys to aluminium, titanium, manganese, cast steel, grey cast iron, brass, bronze and all stainless steels V2A, V4A, INOX etc. Due to the environmentally friendly, petroleum-free, chlorine-free and sulphur-free formulation, the high-performance cutting paste not only offers longer tool life, but also leaves no greasy oil film on the workpieces.

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A. S.p.A. has always stood out for its multitechnological capabilities and highperformance manufacturing, efficiently and flexibly carrying out the entire production cycle of each fitting, starting from forging through to the final testing phase and any relevant certifications. STANDARD FITTINGS and UNIONS are high quality products that can be supplied both threaded (according to ASME B1.20.1) and socketweld, as well as SWAGE NIPPLES that are available in all standardised variants threaded, BW, plainend, eccentric. This family of standard products is available in carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and others. The material can be certified NSF 61, NACE, PED, and Norsok.

Request for a quote

M.E.G.A. SPA

Italy

The SPECIAL PRODUCTS section includes all FITTINGS, NOZZLES and SPECIAL FLANGES made to specific customer requirements in the following materials carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and other metals. HEAVY WALL FITTINGS are manufactured from customer specifications, or from accurate design according to the requirements of international codes, including ASME B31.1, B31.3, B31.4, B31.8, ASME B&PV Code Section I, Section III, Section VIII Division 1 and Division 2, PED, RCCM, EN 13480, EN 10253 or others, and is supported by finite element analysis or calculation reports. In this product category, we have special tees (e.g. two, three or more branch outlets), special wyes (two, three or more ways, with piggability requirements), special caps, special flanges (e.g. swivel flanges, anchor flanges) and flanged fittings, and many other types of fittings designed and developed according to specific requirements.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide cloth, X Flex weight. Main features and benefits: Excellent combination of user friendliness and durability. The cloth used ensures a perfect balance of flexibility and strength. The abrasive tool is efficiently driven by means of a unique 4-split-pin system. Recommended applications: Finishing large flat, concave or convex surfaces; grinding the inner and outer surfaces of tanks and containers. Removing and cleaning weld beads. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic, plastic reinforced by fibre glass, marble, stone.

Request for a quote

BIBIELLE S.P.A.

Italy

This nonwoven abrasive material is converted into rolls to be cut to the desired length so as to avoid wastage. Main features and benefits: Extremely flexible and handy. Excellent cutting performance and resistance to clogging. Easy to clean using compressed air or water. Recommended applications: Cleaning parts of irregular shape, removing scale, grease and paints. Removing marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass.

Request for a quote

BIBIELLE S.P.A.

Italy

This nonwoven abrasive material is converted into convenient pre-cut sheets. Can be used manually or on orbital sanders. Main features and benefits: Extremely flexible and handy. Excellent cutting performance and resistance to clogging. Easy to clean using compressed air or water. Recommended applications: Cleaning parts of irregular shape, removing scale, grease and paints. Removing marks left by previous operations Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass.

Request for a quote

BIBIELLE S.P.A.

Italy

The STRIP-IT RED material is more rigid with faster cut and longer life compared to the black one. Main features and benefits: The STRIP-IT RED offers a longer lifetime in heavy application. Recommended applications: STRIP-IT RED is used for mechanically cleaning all types of welding, for rapidly removing scale and oxidation, for satin finishing small surfaces, for removing paints or other clogging materials such as salt, rust, grease, oil and protective waxes. Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium discs, Y-weight backing. Main features and benefits: Zirconium ensures highly efficient removal in all applications requiring high operating pressure. Recommended applications: Mould making, manufacture of small-sized tanks and equipment Work surfaces: Stainless steel, alloyed steel, titanium, glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium discs, Y-weight backing. Main features and benefits: Zirconium ensures highly efficient removal in all applications requiring high operating pressure. Recommended applications: Mould making, manufacture of small-sized tanks and equipment. Work surfaces: Stainless steel, alloyed steel, titanium, glass fibre.

Request for a quote_2d1389ce.jpg)

BIBIELLE S.P.A.

Italy

This SCHD Heavy Duty material can be converted into into custom-made sizes at the customer’s request. Main features and benefits: Fast and heavy cutting performance combined with highly efficient stock removal can help operators avoid one or more abrasive operations Recommended applications: Cleaning parts made of stainless steel, aluminium or other metals, deburring, removing thin TIG or MIG weld beads and removing scale. Work surfaces: Stainless steel, standard or alloyed steel, titanium, nonferrous materials and alloys.

Request for a quoteBIBIELLE S.P.A.

Italy

This SCLS Low Stretch material can be converted into custom-made sizes at the customer’s request. Main features and benefits: Long life, good cutting performance and consistent finishing quality, user friendliness, excellent tensile strength. Recommended applications: Cleaning parts made of stainless steel, aluminium or other metals, satin finishing small or large surfaces, light deburring, cleaning marks left by previous operations and removing scale Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass.

Request for a quote

BIBIELLE S.P.A.

Italy

BUW material applied on a stiff fibre backing to be used on angle grinders. Main features and benefits: Thanks to the high speed the BUF works fast on large work surfaces. No backup pad is needed. Recommended applications: Deburring, Cleaning, Blending and Finishing and polishing of a wide range of parts. Work surfaces: Any kind of metal (stainless steel, titanium, aluminium, alloys), plastic and composite.

Request for a quote

BIBIELLE S.P.A.

Italy

BUW material made in quick change discs. Main features and benefits: The quick change discs can be used in areas difficult to reach as the BUW material can be used on the two faces and on the external diameter. Recommended applications: Deburring, Cleaning, Blending and Finishing and polishing of a wide range of parts. Work surfaces: Any kind of metal (stainless steel, titanium, aluminium, alloys), plastic and composite.

Request for a quote

BIBIELLE S.P.A.

Italy

These RG aluminium oxide flap wheels are characterized by extremely compact design, 3-mm diameter cylindrical shaft and X-Flex weight backing. Main features and benefits: Being very compact, our Micro RG wheels can be used in confined spaces. The small shaft diameter allows them to be used on light and versatile machine tools. Recommended applications: Finishing moulds, small-sized pipes and cylinders, drilled parts in general. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIBIELLE S.P.A.

Italy

Aluminium oxide flaps and X-Flex weight backing ¼-20 UNC shaft thread. Main features and benefits: Being quick to change, our RG flap wheels on threaded shaft can be ideally used in robotized applications or intensive production lines. In addition to this, it is extremely easy to switch over to a new grit on the same tool by manually unscrewing the wheel. Recommended applications: Finishing small parts, moulds, alloy wheels, robotized applications. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre, rubber, marble.

Request for a quote_b817237e.jpg)

BIBIELLE S.P.A.

Italy

Surface Conditioning material prepared as back up pad discs in fiberglass. Features and benefits: The advantages of the Surface Conditioning is that it gives you the possibility to be used on angled grinders without back up pads. Furthermore, the form of the flap also offers higher durability and a better ventilation. Recommended applications: Plastic products, machinery for the chemical and food industries (manufacture and maintenance), stainless steel furniture, the automotive and railway industries, shipbuilding, the aeronautical industry, propeller and jet engines, stainless steel structural work. Work surfaces: Steel, stainless steel, aluminum, titanium and alloys, fiberglass, plastic and glass.

Request for a quote

BIBIELLE S.P.A.

Italy

Quick-change Surface Conditioning SCSB Scrim Back discs with S fastening system. Not recommended for use in applications requiring considerable mechanical strength. Main features and benefits: Extremely quick to change. Fast and heavy abrasive action, highly efficient escape of waste. Thanks to their compact design, they can be used in hard-to-reach places. Recommended applications: Plastic products, machinery for the chemical and food industries, stainless steel furniture, the automotive and railway industries, the aeronautical industry, stainless steel structural work. Work surfaces: Steel, stainless steel, aluminium, titanium and alloys, fibre glass, plastic and glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

Quick-change Surface Conditioning SCSB Scrim Back discs with R fastening system. Recommended for use in applications requiring considerable mechanical strength. Main features and benefits: Extremely quick to change. Fast and heavy abrasive action, highly efficient escape of waste. Thanks to their compact design they can be used in hard-to-reach places. Recommended applications: Plastic products, machinery for the chemical and food industries, stainless steel furniture, the automotive and railway industries, the aeronautical industry, stainless steel structural work. Work surfaces: Steel, stainless steel, aluminium, titanium and alloys, fibre glass, plastic and glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

SCSB Scrim Back or SCHD Heavy Duty discs with hole. To be fixed by means of metal rings. Main features and benefits: Fast and heavy abrasive action, extremely long life, good rigidity. Ensure excellent flatness and uniformity. Recommended applications: Machinery for the chemical and food industries (manufacture and maintenance), stainless steel furniture, shipbuilding and stainless steel structural work. Work surfaces: Steel, stainless steel, aluminium, titanium and alloys, fibre glass, plastic and glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

SCHD Heavy Duty discs with hole to be fixed by means of metal rings or without hole for velcro locking. To be used with backing pads. Main features and benefits: Extremely heavy abrasive action, extremely long life. Recommended applications: Machinery for the chemical and food industries (manufacture and maintenance), stainless steel furniture, shipbuilding and stainless steel structural work. Work surfaces: Steel, stainless steel, titanium and alloys.

Request for a quoteBIBIELLE S.P.A.

Italy

SCSB Scrim Back discs with hole. To be fixed by means of metal rings. Main features and benefits: Fast and heavy abrasive action, high unloading properties, extremely long life. Recommended applications: Plastic products, machinery for the chemical and food industries (manufacture and maintenance), stainless steel furniture, the automotive and railway industries, shipbuilding, the aeronautical industry, propellers and jet engines, stainless steel structural work. Work surfaces: Standard steel, stainless steel, aluminium, titanium and alloys, fibre glass, plastic and glass fibre.

Request for a quoteBIBIELLE S.P.A.

Italy

SCSB Scrim Back discs without hole. To be fitted on Velcro backup pads Main features and benefits: Fast and heavy abrasive action, high unloading properties, extremely long life, quick to change. Recommended applications: Plastic products, machinery for the chemical and food industries (manufacture and maintenance), stainless steel furniture, the automotive and railway industries, shipbuilding, the aeronautical industry, propellers and jet engines, stainless steel structural work. Work surfaces: Steel, stainless steel, aluminium, titanium and alloys, fibre glass, plastic and glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

The STRIP-IT RED material is more rigid with faster cut and longer life compared to the black one. Main features and benefits: The STRIP-IT RED offers a longer lifetime in heavy application. Recommended applications: STRIP-IT RED is used for mechanically cleaning all types of welding, for rapidly removing scale and oxidation, for satin finishing small surfaces, for removing paints or other clogging materials such as salt, rust, grease, oil and protective waxes. Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass, stone or wood.

Request for a quote

BIBIELLE S.P.A.

Italy

The STRIP-IT RED material is more rigid with faster cut and longer life compared to the black one. Main features and benefits: The STRIP-IT RED offers a longer lifetime in heavy application. Recommended applications: STRIP-IT RED is used for mechanically cleaning all types of welding, for rapidly removing scale and oxidation, for satin finishing small surfaces, for removing paints or other clogging materials such as salt, rust, grease, oil and protective waxes. Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass, stone or wood.

Request for a quote

BIBIELLE S.P.A.

Italy

The STRIP-IT RED material is more rigid with faster cut and longer life compared to the black one. Main features and benefits: The STRIP-IT RED offers a longer lifetime in heavy application. Recommended applications: STRIP-IT RED is used for mechanically cleaning all types of welding, for rapidly removing scale and oxidation, for satin finishing small surfaces, for removing paints or other clogging materials such as salt, rust, grease, oil and protective waxes. Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass, stone or wood.

Request for a quoteBIBIELLE S.P.A.

Italy

This SCXF X-Flex material can be converted into custom-made sizes at the customer’s request. Main features and benefits: Extremely flexible, does not delaminate even if used with 3 mm diameter contact wheels. Easy to fit on very compact machinery. Recommended applications: Cleaning parts made of stainless steel, aluminium or other metals, satin finishing small surfaces, light deburring or removing TIG or MIG weld beads on hard-toreach places, cleaning marks left by previous operations and removing scale. Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass.

Request for a quoteResults for

Titanium alloys - Import exportNumber of results

37 ProductsCompany type