- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shafts

Results for

Shafts - Import export

ELAP AUTOMAZIONE INDUSTRIALE

Italy

The range of incremental encoders fit to be coupled to motor shafts includes different mechanical types: the series RE400, with flange diameter 53.5 mm and RE470, with flange diameter 72 mm, provide a coupling joint, while the series RE410 and RE450 avail on a hollow shaft. Different measures are available for the joint hole and for the shaft diameter. All the types are housed in a metal case. The connection type and position can be chosen among different options, as well as the output signal formats. The pulses per revolution number ranges from 2 to 12500. The zero reference pulse option is available for all the series (type RE401/RE411/RE451/RE471)

Request for a quote

MIX SRL

Italy

Main features • Short mixing time • Extremely high mixing quality • Batches with repeatable results • Mixing ratio 1/100.000 • Coefficient of variation (CV): ≤ 3 % • Low maintenance • Easy deep cleaning Techanical features • Batch size: from 65 to 28.000 liters (net) • Cylindrical mixing chamber • MIxing tools: ploughshare / ploughshare with toothed design / Mix Paddle / Mix Paddle with toothed design • Material of costruction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti • Full access to mixing chamber through the extractable rotor shaft • Inspection door complete with safety electric lock • Discharge door with round profile, building the bottom side of the mixing chamber • Rotor shaft with turned and coaxial ends • Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen

Request for a quote

ITALGEAR SRL

Italy

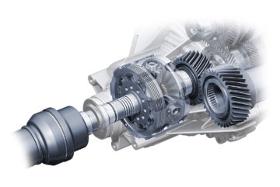

The common roots shared with the Poppi Forging Industries provide ITALGEAR a facilitated access to the forging facilities of the Group and particularly the ability to source electrical upsetted parts with dimensions that are predetermined by specific software’s that allow minimizing the stock material hence resulting into superior quality and price effectiveness of the finished product. Gears of shafts and axle shafts, after their heat treatment, can also be finished with the use of the Skiving technology that makes use of specific hard metal hobbing tools that are PVD coated. The Skiving technology allows production of gears that combine a high quality finishing with reduced machining time and costs.

Request for a quote

ITALGEAR SRL

Italy

Over the years ITALGEAR has gained an extensive experience in the field of industrial gearboxes and complex transmission drives, collaborating, when requested, with the Customer for the optimization of the gears and their kinematics. ITALGEAR’s competence extends both to the production of gears and geared shafts, and to the complete assembly of the entire transmission unit. The production process is fully traced, including control activities, in order to guarantee the conformity of the finished product. Speed reducer manufacturers can therefore exploit ITALGEAR’s technical resources to outsource their production, in whole or in part, and thus rely on a specialized and skilled supplier when market conditions suggest flexibility.

Request for a quote

ELAP AUTOMAZIONE INDUSTRIALE

Italy

The range of incremental encoders with 58 mm round flange includes different mechanical types: the series RE520, with centering mask diameter 50 mm, compatible with the international standard SIZE23, RE540, with centering mask diameter 36 mm and RE510 with centering mask diameter 31.75. All the types are housed in a metal case. The connection type and position can be chosen among different options, as well as the output signal formats and the shaft diameters. The pulses per revolution number ranges from 2 to 12500. The zero reference pulse option is available for all the series (type RE521 etc.).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELAP AUTOMAZIONE INDUSTRIALE

Italy

The range of square-flanged incremental encoders includes the series RE620, with centering mask diameter 31.75 mm, compatible with the international standard SIZE25, and the series RE650, with centering mask diameter 50 mm. Both the types are housed in a metal case. The connection type and position can be chosen among different options, as well as the output signal formats and the shaft diameters. The pulses per revolution number ranges from 2 to 12500. The zero reference pulse option is available for both series (type RE621 – RE651).

Request for a quote

ELAP AUTOMAZIONE INDUSTRIALE

Italy

The small size encoders series E40 feature great accuracy and compact size. The incremental encoder E40 can be supplied with different mechanical flanges: the type E40 has 6 fixing holes on diameter 30 mm, while the type 40A has 4 holes on diameter 25.4 mm; the encoder E40V has a front fixing screw, and the series E40Q is provided with a square flange of mm 43×43. The types E40M and E40S are hollow shaft encoders designed for motor coupling, respectively by joint and by anti-rotational elastic metal support. For all the types the ppr no. ranges from 2 to 12500, with or without zero pulse (E40 or E41). The series standard case is out of ABS plastics, with axial or radial cable or connector outlet; series RE40 with aluminium housing and IP65 radial cablepress outlet is also available.

Request for a quote

ELAP AUTOMAZIONE INDUSTRIALE

Italy

Compact sized encoders series REC fit to any application where short body dimensions are required – the case length only measures 38 mm. REC encoders are available with different mechanical versions: with round flange and servo copling (type REC520/REC540), square flange (REC620) or hollow shaft, with (REC450) or without elastic support(REC440). The case is out of strong aluminium and connections are ensured by the connector type M12, or optionally by cable. The encoder with M12 connector output is UL Listed for the canadian and US markets. The pulses per revolution number ranges from 2 to 12500.

Request for a quote

M SERVICES SRL

Italy

The CNC machine, mod. TB412Y is designed for reduced tooling and programming time. Is a double spindle machine and it has got an upload station on self-positioning rollers, able to receive bars from diameter of 12 mm up to 110 mm, variable from a length of 150 mm up to 3000 mm. Ground pliers and micro filtered refrigeration allows machining of shafts without damages of the chrome surface. The 12 positions, motorized tool turret, on which you can install up to 24 tools, has got an Y axis for milling and holes machining , also off-axis. The unload of the workpiece from the sub -spindle is totally automatic. The simplicity of the use, the high versatility and precision in machining, make model TB412Y an extremely competitive machine, making it possible whoever to realize quickly any kind of chromed bar. The software, made by us, is integrated with CNC SIEMENS 840 Di, and it is customizable.

Request for a quote

LIKA ELECTRONIC S.R.L.

Italy

Lika offers a complete range of Profinet-certified absolute encoders. Available in both low cost 27-bit resolution multiturn EM- series and high resolution singleturn (18-bit) and multiturn (30-bit) H-series, Profinet IO encoders fully comply with the Encoder Profile Specifications V4.1 version 3.162 based on the PROFIdrive profile. Furthermore they fulfill the requirements of the Application Classes 3 and 4 and support both the RT real-time transmission mode and the IRT isochronous real-time mode to meet precise and deterministic data exchange needs (jitter less than 1 µs and cycle time down to 1 ms). Profinet encoders support the standard telegrams 81, 82, 83 and 84 and implement advanced functions such as full scaling, preset, code sequence, position and velocity readout, diagnostic information. Among the key benefits: real time communication, deterministic synchronization, complete diagnostics, IT integration.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide flaps and X-Flex weight backing ¼-20 UNC shaft thread. Main features and benefits: Being quick to change, our RG flap wheels on threaded shaft can be ideally used in robotized applications or intensive production lines. In addition to this, it is extremely easy to switch over to a new grit on the same tool by manually unscrewing the wheel. Recommended applications: Finishing small parts, moulds, alloy wheels, robotized applications. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre, rubber, marble.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide flaps and X-Flex weight backing. 6-mm diameter cylindrical shaft. Main features and benefits: These wheels are our most versatile RG tools. Robust and suitable for numerous applications on work surfaces of various kinds. Excellent flexibility. Recommended applications: Finishing, light deburring, cleaning or preparation for subsequent treatments (chromium plating, nickel plating or painting) on small or hard-toreach surfaces such as the internal surfaces of pipes, cylinders, parts of irregular shape. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre, rubber, marble, stone, concrete, wood, hide or leather

Request for a quote

BIBIELLE S.P.A.

Italy

These wheels on 6-mm shaft are made of a combination of cloth flaps and High Performance Nonwoven material. To be used on straight grinders. Main features and benefits: Thanks to the abrasive cloth the scrubbing action of BIBIELLE shaft-mounted nonwoven wheels is more aggresive whilst ensuring high finishing quality, excellent user friendliness combined with highly efficient ventilation and low-noise levels typical of nonwoven products. Recommended applications: Light deburring and cleaning parts of irregular shape, pipes or moulded parts. Removing scale. Removing marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium.

Request for a quoteResults for

Shafts - Import exportNumber of results

14 ProductsCountries

Company type