- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production line

Results for

Production line - Import export

FERPLAST SNC

Italy

New packaging machine with transparent bell RP series with solid steel structure, the latest generation of electronic, front control interface, intuitive programming, more space in the packaging space and a whole host of technical features that enhance performance yet. Three models are available with a support surface of mm. 400x250x200h - mm. 520x390x250h - mm. 580x780x250h. The dimensions of the support surface are to be considered with the hood closed. The volume cannot be completely filled by the box or by the product to be packaged as space must always be left for the passage of hot air around the product.

Request for a quote

BLUE LINE PROJECT SPA

Italy

A flexible business structure that combines experience and creativity, in-depth knowledge of markets and trends on one hand, and suppliers, materials and treatments on the other. This means we can carefully assess the feasibility of every design project, steering it towards success. Our business division follows clients who already have their own style, market and trends, simplifying the optimisation of processes through the selection of the best possible fabrics and the most suitable types of treatment process. Our pro-active business division offers exclusive consultancy services on design and trends to clients who require them throughout the production process. With eyes open for trends in the world’s fashion capitals, this team can guarantee

Request for a quote

AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

Italy

AIC – Automazioni Industriali Capitanio is a global system integrator providing advanced and tailored automation and robotic solutions for the steel industry, with the aim to continuously improve both efficiency, competitiveness and safety of the production processes. With more than 1000 applications worldwide and more than 40 years of history, AIC can boost an unique experience in both greenfield and revamping projects in meltshops, continuous casting machines and long products rolling mills. Thanks to the team of over 70 highly skilled professionals, the company designs, manufactures and commissions turn-key electrical, automation, PLC safety systems and robotic applications, ensuring long-time experience and technical know-how for engineering, AC and DC drives, PLC and SCADA for complete Levels 0, 1 and 2 automation and process control that are the critical issues of Mini Mills. For more information please visit the website www.aicnet.it or send us an email at aic@aicnet.

Request for a quote

TOPPY PACKAGING

Italy

Master Toppy is our top performing pile turner for turning, vibrating and aligning stacks up to 3000Kg. Ideal when used in-line with die-cutting and laminating machines.

Request for a quote

SEIT ELETTRONICA SRL

Italy

Platinum HUB is a scalable platform you can customize according to your brazing process. You can set up the layout adding multiple stations to: flux, apply brazing paste or pre-formed brazing alloy, wash, dry and cool the parts you are processing, mark with galvo laser technology, and automatic loading and unloading the line using co-bot or industrial robots. This system will for sure adapt to your process and needs and will give you the chance to expand it and add new functions when you really need it. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fits with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the key data from your production as cycle time, temperature and more.

Request for a quote

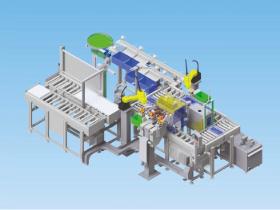

ARS AUTOMATION

Italy

FlexiBowl® is the flexible parts feeding system for automated production lines using industrial robot or cobots. It is patented and produced by ARS S.r.l. and sold in more than 40 countries worldwide, including through authorized distributors. FlexiBowl® optimizes parts feeding by ensuring more parts are available for pick-up by the gripper in every cycle. The system improves overall feed rates, increases productivity and reduces changeover times.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Production line - Import exportNumber of results

6 ProductsCountries

Company type