- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial machinery

Results for

Industrial machinery - Import export

FDT SRL DEPURATORI D'ACQUA

Italy

The fdt dosing stations are made entirely at our factory with the best materials and according to the latest manufacturing techniques. They find applications in all the complementary treatment of water by injection of appropriate chemicals. The fdt Ltd metering stations thanks to the modern design of the injection units and a modern and efficient control systems allows a fully automatic operation. Function and are covered by fdt Ltd warranty, design risk by leading insurance company.

Request for a quote

AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

Italy

AIC manufactures and supply PLC platforms, AC&DC drives panels suited to allow an enhanced power control of each equipment using all the drives available on the market, such as Rockwell Automation, ABB, Siemens, Nidec, Schneider, according to the customer needs/requirement. The power control supply includes: - AC Medium voltage panels suited with dedicated power transformers, up to 7MW; - Low voltage AC Drives: Single motor drives, Multidrives with DC Bus supplier; - Low voltage DC Drives; - Soft-starter for smooth acceleration; - MCC for fixed speed drive design; - AC & DC motor and gear motor basic & detailed design and supply.

Request for a quote

AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

Italy

GENERAL OPERATION The machine is built-up of a rotating plate and a knot device that allow to create the requested wire ties. When the cycle is running, the pinch roll insert the wire in the machine and the rotating plate starts to rotate creating the wire ties. The crossed ends of the wire are held together and twisted by rotation of the gripper. AUTOMATIC CYCLE When the operator press the “start” button, the automatic cycle command is sent to the machine. This signal allow to insert the wire into the rotating plate following the sequence below: - Realignment and lifting of the twister. - Realignment of the wire step cylinder. - Closing of the pinch roll. - Moving forward of the puller. - Insertion of the wire by means of forward rotation of the pinch roll. When the twister is in high position, the puller is moved forward, in order to pull out the wire ties. With a time delay, the machine starts a new tying cycle (according to the number of the ties set in the operator’s panel).

Request for a quote

AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

Italy

Brand: ATS Mechatronics - Automazioni Industriali Capitanio (AIC) Min stack size: 300 x 300 mm Max stack size: 1100 x 1100 mm Wire diameter (upon customer's request): 5,5 ÷ 8 mm Knot position: 45 degrees Number of turns (Selectable via control panel): 1 or 2 Turn type (Selectable via control panel): Tight or Loose Installed power: 35 kW Working pressure: 120 bar (Hydr.) Tying cycle: 11,5 s

Request for a quote

TAVENGINEERING

Italy

Need the furnace but not the cost? We supply completely refurbished vacuum furnaces that may be adapted to fit your needs. For a cost-effective solution, look into our reconditioned equipment and systems – tested to operate efficiently, reliably, safely.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

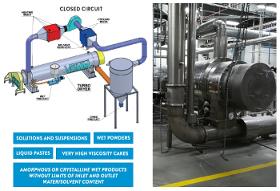

VOMM IMPIANTI E PROCESSI SPA

Italy

Turbo Dryer operates with any type of wet solid, liquid or pasty product, independently of its moisture content, viscosity and consistency. Turbo Dryer is widely used for partial or full drying in water or solvent precence. Pilot plant is available in VOMM R&D department in Rozzano.

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

Deep groove ball bearings are the most commonly used type of bearing. Coming in many versions, varieties and dimensions, they are particularly versatile and can be used in a wide range of applications. They can withstand both radial and axial loads in both directions, even at high speed. They are especially suitable for all situations where high speed and low power loss are required. Features of deep groove ball bearings: ideal for high and very high speeds able to bear medium radial and axial loads in one or both directions easy to assemble, with minimal maintenance requirements Series: 600, 6000, 6200, 6300, 6400, 1600 Thin ring: 61800, 61900 APPLICATIONS: Earth Moving Machinery Electrical Motors and Gearboxes Iron and Steel Industry Agricultural Machinery Oil Industry Papermaking Machinery Wind Turbines Railways Semiconductors General mechanics Industrial Transmissions Pumps and Compressors Medical devices Food Processing Machinery

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

Self-aligning ball bearings are radial bearings with two rows of balls, a common spherical track in the outer ring and a track with two deep and continuous grooves in the inner ring. They are particularly suitable for applications that are prone to alignment errors. Features of self-aligning ball bearings: low coefficient of friction exceptional performance at high speeds no overheating, lower operating temperatures excellent compensation for misalignments ideal for low to medium-high radial loads and reduced axial loads available in open or shielded versions (ZZ – 2RS) and with tapered bore (K) very low noise and limited vibrations minimal maintenance requirements Series: 1200, 1300, 2200, 2300, 11200, 11300 APPLICATIONS: Agricultural Machinery Oil Industry Electrical motors and gearboxes Medical devices Food processing machinery Chemical Industry Pumps

Request for a quoteResults for

Industrial machinery - Import exportNumber of results

9 ProductsCountries

Company type

Category