- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water plants

Results for

Water plants - Import export

ROSSI INGEGNERIA ALIMENTARE SRL

Italy

We offer process solutions for all types of fruit and for all stages of production: from the delivery of fresh fruit, through extraction or pressing to the final packaging of the juice aseptically or by hot filling. Alternatively, we build plant for the preparation of quality juice, starting from pureés and concentrates in aseptic drums, while respecting the organoleptic properties of the fruit. In both cases, our technologies ensure that a homogeneous and natural liquid is obtained thanks to a perfect combination of the blended products. All Ing.A.Rossi production plant is highly automated, and can be operated from a control room, in order to minimise operator error and guarantee repeatability and precision in the process. Production lines can also be integrated with waste water purification plants, and can cater for both small and large-scale production: we don’t have any volume limits. Extraction, pressing or preparation of highest-quality

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The flow of water and sludge coming from the previous phases of treatment (whether biological or physical-chemical) is introduced into the intermediate zone of the tank, just below the lamellar pack. Lamellar pack single-piece clarifiers for the sludge settling. They are composed of: containment tank which can be manufactured from, at choice, treated and paintedcarbon steel or in AISI 304 stainless steel; lamellar pack with parallel channels in rigid polystyrene, stabilized against UV radiation; surface discharge trough (with weir) in AISI 304; intermediate distributor of the feed flow. Special materials and executions are available on request. FM – L SERIES (11,30 m2/m3 equivalent surface) Typical applications: secondary clarification of biological sludge, drinking water plants, upgrading of existing clarifiers, rain water treatment. -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The flow of oil and water is introduced to the tank and distributed in a homogeneous way across the whole cross-section. They are composed of a containment tank which can be manufacturedfrom treated and painted carbon steel or AISI 304 stainless steel; lamellar pack with parallel channels in rigid polystyrene, stabilized agains UV radiation. Special materials and executions are available on request. Typical applications: first fall rain water, petrochemical plants, mechanical workshops, refineries and depots of hydrocarbons, washing of vehicles, land reclaim, refuse handling centres. -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quote

TECNIDRO

Italy

Hydraulically or Pneumatic operated. TYPICAL APPLICATIONS Irrigation, water treatment, animal feeding plants

Request for a quote

TECNIDRO

Italy

Hydraulically or Pneumatic operated. TYPICAL APPLICATIONS Irrigation, water treatment, animal feeding plants.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IKOI SPA

Italy

ALS® – Acidless Separation® by IKOI is a revolution in the metal refining industry. It achieves silver and gold separation without any chemicals. This Green Technology has obvious benefits for the environment and the communities, as well as a positive effect on the economics of the industry. ADVANTAGES OF ALS®: No use of chemicals. ALS® is a real Green technology No Precious Metals losses Fast process Safety and security No need of Precious Metals lock-up Easy metal control and accountability at every step of the process Easy to use Flexible (it can process a wide range of alloys) Low OPEX Low Maintenance No need of additional equipment (scrubbers, filters, waste water treatment plants etc.)

Request for a quote

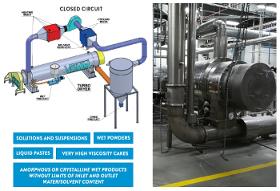

VOMM IMPIANTI E PROCESSI SPA

Italy

Turbo Dryer operates with any type of wet solid, liquid or pasty product, independently of its moisture content, viscosity and consistency. Turbo Dryer is widely used for partial or full drying in water or solvent precence. Pilot plant is available in VOMM R&D department in Rozzano.

Request for a quoteResults for

Water plants - Import exportNumber of results

8 ProductsCountries

Company type