- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- time temperature

Results for

Time temperature - Import export

FERPLAST SNC

Italy

Heat-sealing roller FP802/803 with constant heat which allows the sealing of bags and heat-sealable materials. This roller allows you to make seals with different shapes (square, circular, etc.) according to your needs. Once the roller has been switched on, the operator must wait for the roller to warm up for about 10 minutes. The temperature is adjustable via a potentiometer and reaches a maximum of 200 ° C. There is no graduated scale. The temperature must therefore be set following practical tests on the material. The use is manual. The pressure, the sealing time and the temperature must be managed by the operator. The sealing result depends exclusively on its ability and therefore the result can vary between seals. The coating of the anti-adhesive Teflon roller allows to seal bags in polypropylene, polyethylene and laminated materials. It is supplied complete with a mat in silicone material which, positioned under the product to be sealed, is the ideal match for sealing.

Request for a quote

FERPLAST SNC

Italy

Semiautomatic impulse heat sealers for the bench, for closing PE, PP, PVC and light coupled bags. Equipped with timer, pedal and trimmer. They can be used for: food products, in the automotive, cosmetics, electronics, mechanical and plastic parts, packaging for e-commerce, pellets and agriculture and for chemical products. Available in 460mm and 610mm welding lengths, and 4mm high. Suitable for bags of different thickness, with moist or dusty contents. Double sealing bar with separate regulation of temperatures and times. Manual and semi-automatic operation with electromagnetic closure. Adjustment of the welding power by means of a 6-position switch. Activation by electric pedal or automatic cycle button with digital control of the welding parameters. Digital timer with LCD, for precise control of welding (0-10 sec.) And cooling (0-20 sec.) Times. Can be combined with dosing systems.

Request for a quote

MIX SRL

Italy

Main features • Management of the process time and temperature through the heat exchanger • Short mixing time • Extremely high mixing quality • Batches with repeatable results • Mixing ratio 1/100.000 • Coefficient of variation (CV): ≤ 3 % • Low maintenance Techanical features • Batch size: from 65 to 28.000 liters (net) • Cylindrical mixing chamber • MIxing tools: ploughshare / ploughshare with toothed design / Mix Paddle / Mix Paddle with toothed design • Material of costruction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti • Inspection door complete with safety electric lock • Discharge door with round profile, building the bottom side of the mixing chamber • Rotor shaft with turned and coaxial ends • Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen • Heat exchanger on mixing chamber for heating / cooling processes

Request for a quote

FERPLAST SNC

Italy

Digital and semiautomatic bench sealer, with electric pedal and sealing bars at constant temperature, for closing polypropylene bags and laminated / laminated aluminum, paper, barrier materials, etc. The "hot bar" type sealing bars are equipped with resistance and electronic thermoregulator. Thanks to the new latest generation electronic control card, all controls, adjustments and alarms are more easily set. The digital control of temperature, time and pause interval, it is more precise and functional, thanks to the new control panel, and to the large 1-line by 16-character alphanumeric LCD display. Temperature adjustment 0-150 ° C, with alarm of ± 5 ° C with respect to the set temperature. The closing of the bars takes place by means of an oversized electromagnet which guarantees a high sealing pressure and allows the sealing of high thickness envelopes with or without side gussets. For a higher production it is sufficient to select the automatic cycle with timed closing.

Request for a quote

MARTIN GROUP SRL

Italy

MEPP series machines are equipped, unic on the market, with a patented pressure system that give to machine irreplaceable property: the pressure is not given by two rigid plans (system that don't give you uniformity) MEPP pressure is given by a cautciou membrane that swells by the compressed air, this membrane swell giving you an uniform pressure in every square centimeter of the working plane, also when you are using materials with different thickness in the same working cicle. Machine for various applications, it allows productions with the highest quality. Adjustable time, pressure and temperature Coverings and paddings with thermical and mechanical high resistance Two working plans allow to work in alternated way without dead times THE LUNG MEMBRANE SYSTEM, AGAINST THE RIGID PLANS, ALLOW TO OBTAIN A FIVE TIMES POWERFULL PRESSURE XTP Version: Special version for high pressures, up to 2 Kg/cm2, 230°C With reinforced structure for high pressure and high temperature

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROTEC RIGA INTERNATIONAL

Italy

Professional electromagnetic induction cooking plates. Complete table-top appliances with glass-ceramic top and complete built-in appliances. They have many programmable functions such as choice of power on multiple levels, time and/or temperature setting which ensure personalized and simple professional use. Numerous functions and automatic safety devices such as overheat protection, fault detection, circuit protection sensor and high voltage protection ensure maximum operational safety and reliability.

Request for a quote

EUROTEC RIGA INTERNATIONAL

Italy

Professional electromagnetic induction cooking plates. Complete table-top appliances with glass-ceramic top and complete built-in appliances. They have many programmable functions such as choice of power on multiple levels, time and/or temperature setting which ensure personalized and simple professional use. Numerous functions and automatic safety devices such as overheat protection, fault detection, circuit protection sensor and high voltage protection ensure maximum operational safety and reliability.

Request for a quote

SAATCHITECH.SRL

Italy

Description: Hair straightener to save time is crucial in making sure you get silky smooth hair sections with just one pass and on any hair type. It heats up in just few seconds thanks to its energy-efficient ceramic heaters, so you can spend less time waiting around for it to reach your ideal temperature and more time perfecting (and showing off) your look. Technical Features: •Maximum temperature: 230℃ •360° Swivel cord •Ceramic plate •Temperature control button •LED display •Power supply: 220-240V 50/60Hz 35W •Cable length: 2m Components of Package: •1 Ceramic hair straightener •1 User instructions IT, FR, IT, ES, DE

Request for a quote

SEIT ELETTRONICA SRL

Italy

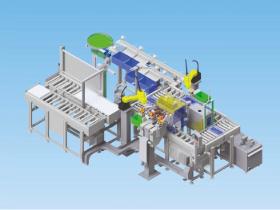

Platinum HUB is a scalable platform you can customize according to your brazing process. You can set up the layout adding multiple stations to: flux, apply brazing paste or pre-formed brazing alloy, wash, dry and cool the parts you are processing, mark with galvo laser technology, and automatic loading and unloading the line using co-bot or industrial robots. This system will for sure adapt to your process and needs and will give you the chance to expand it and add new functions when you really need it. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fits with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the key data from your production as cycle time, temperature and more.

Request for a quoteResults for

Time temperature - Import exportNumber of results

10 ProductsCountries

Company type