- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel alloys

Results for

Steel alloys - Import export

NOVACCIAI MARTIN SPA

Italy

Ground bars Alloy Steel, Non-Alloy Steel and Stainless Steel Ø 6,00 ÷ 200,00 (IT9 ÷ IT6) EN 10278

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Round die. Metric, ISO DIN 13. HSSE. DIN 223. Tolerance ISO-6g. For high-tensile materials. Up to 1200 N/mm2. Professional thread cutting Thread standard: Metric, ISO DIN 13 Type: Round die Application: For high-tensile materials Material of product: HSSE Spiral entry: yes For materials: Tensile strength up to: 1200 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Special geometry for high-strength material. Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

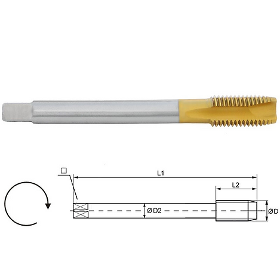

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

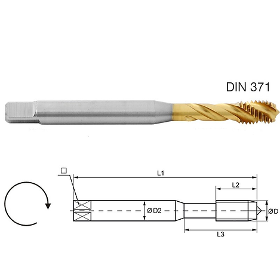

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

NOVACCIAI MARTIN SPA

Italy

Cold drawn bars (+C EN 10277) Alloy Steel, Non-Alloy Steel and Stainless Steel Ø 8,00 ÷ 74,00 ( ≥IT9 ) EN 10278

Request for a quote

NOVACCIAI MARTIN SPA

Italy

Peeled & reeled bars (+SH EN 10277) Alloy Steel, Non-Alloy Steel and Stainless Steel Ø 10,00 ÷ 200,00 ( ≥IT9 ) EN 10278

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium-grained fibre discs – crosscut hole. Main features and benefits: Excellent removal at high pressures, quite a long life and good surface finish. Recommended applications: Deburring, removing welding seams, highly resistant materials. Work surfaces: Stainless steel, alloyed steel, heat-resistant nonferrous materials.

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium-grained fibre discs – round hole. Main features and benefits: Excellent removal at high pressures, quite a long life and good surface finish. Recommended applications: Deburring, removing welding seams, highly resistant materials. Work surfaces: Stainless steel, alloyed steel, heat-resistant nonferrous materials.

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium discs, Y-weight backing. Main features and benefits: Zirconium ensures highly efficient removal in all applications requiring high operating pressure. Recommended applications: Mould making, manufacture of small-sized tanks and equipment Work surfaces: Stainless steel, alloyed steel, titanium, glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium discs, Y-weight backing. Main features and benefits: Zirconium ensures highly efficient removal in all applications requiring high operating pressure. Recommended applications: Mould making, manufacture of small-sized tanks and equipment. Work surfaces: Stainless steel, alloyed steel, titanium, glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

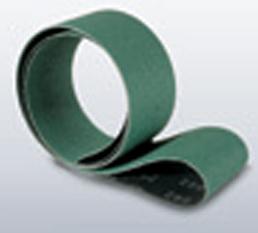

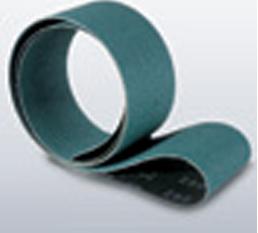

Y-weight polyester backing, Zirconium grain with cooling additive, double resin, closecoat. Main features and benefits: This product is particularly suitable for applications requiring highly efficient removal, extremely quick cutting performance and low operating temperature. This product can be supplied in customised sizes. Recommended applications: Deburring, removing protruding welded surfaces and excess material, removing scale. Work surfaces: Stainless steel, alloyed steel, aluminium, cast iron.

Request for a quote

BIBIELLE S.P.A.

Italy

Economic version of the flap discs. Available in back up pad discs and fiberglass version. Features and benefits: These discs offer good cutting and have a good ratio cost/performance. These are particularly suitable for non continuous processing where cutting speed and costs are the main elements. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium, plastic, pain, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

Economic version of the flap discs. Available in back up pad discs and fiberglass version. Features and benefits: These discs offer good cutting and have a good ratio cost/performance. These are particularly suitable for non continuous processing where cutting speed and costs are the main elements. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium, plastic, pain, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

Y-weight polyester backing, Zirconium grain, double resin, close coat. Main features and benefits: Extremely long life and highly efficient removal. Medium/high operatingpressures are required. This product can be supplied in customised sizes. Recommended applications: Grinding and cleaning, deburring, removing small protruding weldedsurfaces or welding spots. Work surfaces: Stainless steel, alloyed steel.

Request for a quote

BIBIELLE S.P.A.

Italy

Y-weight polyester backing, Zirconium grain, double resin, close coat. Main features and benefits: This product is available in the most widely used sizes for industrial grinders. Extremely long life and highly efficient removal. Medium/high operating pressures are required. Recommended applications: Grinding and cleaning, deburring, removing small protruding welded surfaces or welding spots. Work surfaces: Stainless steel, alloyed steel.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium Oxide flaps and X-Flex weight backing. The central wooden hub has a hole allowing it to be fitted on threaded conical shafts. Main features and benefits: Threaded shafts allow you to fit and remove very quickly while reducing balance control. Recommended applications: Finishing wide flat, concave and convex surfaces; grinding the internal and outer surfaces of tanks, containers and pipes; finishing parts of irregular shape. Work surfaces: Stainless steel, standard steel, alloyed steel, nonferrous materials and alloys.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIBIELLE S.P.A.

Italy

These RG aluminium oxide flap wheels are characterized by extremely compact design, 3,17 mm diameter cylindrical shaft and X-Flex weight backing. Main features and benefits: Being very compact, our Micro RG wheels can be used in confined spaces. The small shaft diameter allows them to be used on light and versatile machine tools. Recommended applications: Finishing moulds, small-sized pipes and cylinders, drilled parts in general. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide flaps and X-Flex weight backing ¼-20 UNC shaft thread. Main features and benefits: Being quick to change, our RG flap wheels on threaded shaft can be ideally used in robotized applications or intensive production lines. In addition to this, it is extremely easy to switch over to a new grit on the same tool by manually unscrewing the wheel. Recommended applications: Finishing small parts, moulds, alloy wheels, robotized applications. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre, rubber, marble.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide flaps and X-Flex weight backing. 6-mm diameter cylindrical shaft. Main features and benefits: These wheels are our most versatile RG tools. Robust and suitable for numerous applications on work surfaces of various kinds. Excellent flexibility. Recommended applications: Finishing, light deburring, cleaning or preparation for subsequent treatments (chromium plating, nickel plating or painting) on small or hard-toreach surfaces such as the internal surfaces of pipes, cylinders, parts of irregular shape. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre, rubber, marble, stone, concrete, wood, hide or leather

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide bands to be used (with suitable expanders) on satin finish machines. Main features and benefits: Thanks to their wide abrasive area, they allow operators to rapidly and efficiently work on a wide range of surfaces. Recommended applications: Light deburring, cleaning, finishing small and large surfaces. Removing scale or marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, wood.

Request for a quote

BIBIELLE S.P.A.

Italy

Overlapped pairs of zirconium flaps and X-weight backing. Only the flat version is available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. The flap paired arrangement provides better ventilation and improves scrap/waste escape. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Recommended applications: Deburring, removing welding seams, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 115 - 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

Particularly robust nylon backing. Overlapped pairs of zirconium flaps and X-weight backing. Only the flat version is available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. The flap paired arrangement provides better ventilation and improves scrap/waste escape. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Always use the backing pad for the 165mm-diameter disc. Recommended applications: Deburring, removing welding seams, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium.

Request for a quote

BIBIELLE S.P.A.

Italy

Individually arranged zirconium flaps and X-weight backing. Only the flat version is available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance Recommended applications: Grinding, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 115 - 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

Individually arranged zirconium flaps and X-weight fibreglass backing. Both flat and conical versions are available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 102 200 pcs/diameter 115 160 pcs/diameter 127 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

Individually arranged zirconium flaps and X-weight fibreglass backing. Both flat and conical versions are available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 102 200 pcs/diameter 115 160 pcs/diameter 127 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

These are similar to the Satin Machine wheels but are made laying the non woven in a way that waved edges are obtained. Features and benefits: For applications on wide areas which require a higher uniformity finishing, the RFV allow a higher uniformity among the various steps on the surface. Recommended applications: Satin finishing large surfaces. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminum, cast iron, titanium, plastic.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide cloth, X Flex weight. Main features and benefits: Excellent combination of user friendliness and durability. The cloth used ensures a perfect balance of flexibility and strength. The abrasive tool is efficiently driven by means of a unique 4-split-pin system. Recommended applications: Finishing large flat, concave or convex surfaces; grinding the inner and outer surfaces of tanks and containers. Removing and cleaning weld beads. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic, plastic reinforced by fibre glass, marble, stone.

Request for a quoteResults for

Steel alloys - Import exportNumber of results

29 ProductsCompany type

Category