- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel alloys

Results for

Stainless steel alloys - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

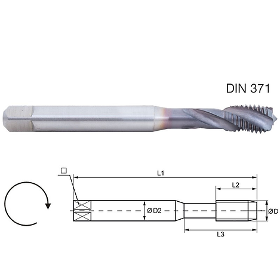

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1400 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

NOVACCIAI MARTIN SPA

Italy

Ground bars Alloy Steel, Non-Alloy Steel and Stainless Steel Ø 6,00 ÷ 200,00 (IT9 ÷ IT6) EN 10278

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A. S.p.A. has always stood out for its multitechnological capabilities and highperformance manufacturing, efficiently and flexibly carrying out the entire production cycle of each fitting, starting from forging through to the final testing phase and any relevant certifications. STANDARD FITTINGS and UNIONS are high quality products that can be supplied both threaded (according to ASME B1.20.1) and socketweld, as well as SWAGE NIPPLES that are available in all standardised variants threaded, BW, plainend, eccentric. This family of standard products is available in carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and others. The material can be certified NSF 61, NACE, PED, and Norsok.

Request for a quote

OMAC SRL

Italy

The B series lobe pumps satisfy most transfer applications to suit hygienic and chemical characteristics. OMAC'S lobe pumps are appreciated all over the world for stoutness and performances, assures good services, long endurance, easy and cheap maintenance.This range consists of 16 models with deliveries from 0.05 to 200 m³/hr with the following versions available ST Model with standard tolerances, SM Model with increased tolerances, both being made in AISI 316 stainless steel and both available with Duplex shafts. HP Model has crescent shaped rotors in antiseizure stainless steel alloy with shafts in Duplex for counter pressures up to 20 Bar. The OMAC Lobe Pump is modular in design allowing the main parts such as the rotor and seals, to be changed quickly and easily. A wide range of rotors, seals and gaskets is also available.

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium discs, Y-weight backing. Main features and benefits: Zirconium ensures highly efficient removal in all applications requiring high operating pressure. Recommended applications: Mould making, manufacture of small-sized tanks and equipment Work surfaces: Stainless steel, alloyed steel, titanium, glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium discs, Y-weight backing. Main features and benefits: Zirconium ensures highly efficient removal in all applications requiring high operating pressure. Recommended applications: Mould making, manufacture of small-sized tanks and equipment. Work surfaces: Stainless steel, alloyed steel, titanium, glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium-grained fibre discs – crosscut hole. Main features and benefits: Excellent removal at high pressures, quite a long life and good surface finish. Recommended applications: Deburring, removing welding seams, highly resistant materials. Work surfaces: Stainless steel, alloyed steel, heat-resistant nonferrous materials.

Request for a quote

BIBIELLE S.P.A.

Italy

Zirconium-grained fibre discs – round hole. Main features and benefits: Excellent removal at high pressures, quite a long life and good surface finish. Recommended applications: Deburring, removing welding seams, highly resistant materials. Work surfaces: Stainless steel, alloyed steel, heat-resistant nonferrous materials.

Request for a quote

BIBIELLE S.P.A.

Italy

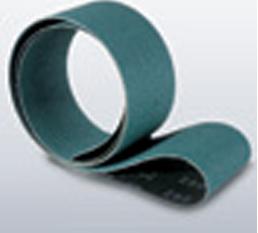

Y-weight polyester backing, Zirconium grain, double resin, close coat. Main features and benefits: Extremely long life and highly efficient removal. Medium/high operatingpressures are required. This product can be supplied in customised sizes. Recommended applications: Grinding and cleaning, deburring, removing small protruding weldedsurfaces or welding spots. Work surfaces: Stainless steel, alloyed steel.

Request for a quote

BIBIELLE S.P.A.

Italy

Y-weight polyester backing, Zirconium grain, double resin, close coat. Main features and benefits: This product is available in the most widely used sizes for industrial grinders. Extremely long life and highly efficient removal. Medium/high operating pressures are required. Recommended applications: Grinding and cleaning, deburring, removing small protruding welded surfaces or welding spots. Work surfaces: Stainless steel, alloyed steel.

Request for a quote

BIBIELLE S.P.A.

Italy

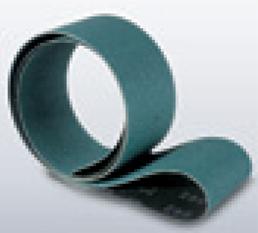

Y-weight polyester backing, Zirconium grain with cooling additive, double resin, closecoat. Main features and benefits: This product is particularly suitable for applications requiring highly efficient removal, extremely quick cutting performance and low operating temperature. This product can be supplied in customised sizes. Recommended applications: Deburring, removing protruding welded surfaces and excess material, removing scale. Work surfaces: Stainless steel, alloyed steel, aluminium, cast iron.

Request for a quote

BIBIELLE S.P.A.

Italy

Economic version of the flap discs. Available in back up pad discs and fiberglass version. Features and benefits: These discs offer good cutting and have a good ratio cost/performance. These are particularly suitable for non continuous processing where cutting speed and costs are the main elements. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium, plastic, pain, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

Economic version of the flap discs. Available in back up pad discs and fiberglass version. Features and benefits: These discs offer good cutting and have a good ratio cost/performance. These are particularly suitable for non continuous processing where cutting speed and costs are the main elements. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium, plastic, pain, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

Y-weight polyester backing available in 40 and 60 grits; Y-weight cotton/polyester backing with additive available in 80/150 grits; aluminium oxide grain, double resin, close coat. Main features and benefits: Extremely long life and highly efficient removal. Coarser grits are suitable for heavy scrubbing of steel and cast iron. Thanks to the additive, 80 and finer grits can be easily used on stainless steel alloys. It is also suitable for wet applications. This product can be supplied in customised sizes. Recommended applications: Grinding and cleaning, deburring, removing small protruding welded surfaces or welding spots. Work surfaces: Standard steel, stainless steel, nonferrous metals, cast iron, alloys.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIBIELLE S.P.A.

Italy

Overlapped pairs of zirconium flaps and X-weight backing. Only the flat version is available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. The flap paired arrangement provides better ventilation and improves scrap/waste escape. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Recommended applications: Deburring, removing welding seams, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 115 - 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

Particularly robust nylon backing. Overlapped pairs of zirconium flaps and X-weight backing. Only the flat version is available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. The flap paired arrangement provides better ventilation and improves scrap/waste escape. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Always use the backing pad for the 165mm-diameter disc. Recommended applications: Deburring, removing welding seams, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium.

Request for a quote

BIBIELLE S.P.A.

Italy

Individually arranged zirconium flaps and X-weight backing. Only the flat version is available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance Recommended applications: Grinding, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 115 - 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

Individually arranged Heavy Duty zirconium flaps and X-weight fibreglass backing. Both flat and conical versions are available. Main features and benefits: The Heavy Duty zirconium cloth is particularly suitable for applications requiring very high operating pressure and for medium/high-power cornering grinders. It is the ideal product for working particularly difficult areas such as irregular edges, sharp corners and electrode welding seams. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Recommended applications: Deburring, removing welding seams and spots, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 102 200 pcs/diameter 115 160 pcs/diameter 127 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

Individually arranged zirconium flaps and X-weight fibreglass backing. Both flat and conical versions are available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 102 200 pcs/diameter 115 160 pcs/diameter 127 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

Individually arranged zirconium flaps and X-weight fibreglass backing. Both flat and conical versions are available. Main features and benefits: The zirconium abrasive is particularly suitable for applications requiring high operating pressure and even for medium/high-power cornering grinders. Wide abrasive surface, constant wear, continuous exposure of new grit, high and even cutting performance. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminium, nonferrous metals and alloys, structural steel, cast iron, titanium. Minimum order quantity for articles not included in 1036 program: 200 pcs/diameter 102 200 pcs/diameter 115 160 pcs/diameter 127 80 pcs/diameter 178

Request for a quote

BIBIELLE S.P.A.

Italy

These are similar to the Satin Machine wheels but are made laying the non woven in a way that waved edges are obtained. Features and benefits: For applications on wide areas which require a higher uniformity finishing, the RFV allow a higher uniformity among the various steps on the surface. Recommended applications: Satin finishing large surfaces. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminum, cast iron, titanium, plastic.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium Oxide flaps and X-Flex weight backing. The central wooden hub has a hole allowing it to be fitted on threaded conical shafts. Main features and benefits: Threaded shafts allow you to fit and remove very quickly while reducing balance control. Recommended applications: Finishing wide flat, concave and convex surfaces; grinding the internal and outer surfaces of tanks, containers and pipes; finishing parts of irregular shape. Work surfaces: Stainless steel, standard steel, alloyed steel, nonferrous materials and alloys.

Request for a quote_2d1389ce.jpg)

BIBIELLE S.P.A.

Italy

This SCHD Heavy Duty material can be converted into into custom-made sizes at the customer’s request. Main features and benefits: Fast and heavy cutting performance combined with highly efficient stock removal can help operators avoid one or more abrasive operations Recommended applications: Cleaning parts made of stainless steel, aluminium or other metals, deburring, removing thin TIG or MIG weld beads and removing scale. Work surfaces: Stainless steel, standard or alloyed steel, titanium, nonferrous materials and alloys.

Request for a quoteBIBIELLE S.P.A.

Italy

This SCXF X-Flex material can be converted into custom-made sizes at the customer’s request. Main features and benefits: Extremely flexible, does not delaminate even if used with 3 mm diameter contact wheels. Easy to fit on very compact machinery. Recommended applications: Cleaning parts made of stainless steel, aluminium or other metals, satin finishing small surfaces, light deburring or removing TIG or MIG weld beads on hard-toreach places, cleaning marks left by previous operations and removing scale. Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass.

Request for a quoteBIBIELLE S.P.A.

Italy

This SCLS Low Stretch material can be converted into custom-made sizes at the customer’s request. Main features and benefits: Long life, good cutting performance and consistent finishing quality, user friendliness, excellent tensile strength. Recommended applications: Cleaning parts made of stainless steel, aluminium or other metals, satin finishing small or large surfaces, light deburring, cleaning marks left by previous operations and removing scale Work surfaces: Stainless steel, standard or alloyed steel, aluminium, titanium, nonferrous materials and alloys, fibre glass, plastic or plastic reinforced by fibre glass.

Request for a quote

BIBIELLE S.P.A.

Italy

BUW material applied on a stiff fibre backing to be used on angle grinders. Main features and benefits: Thanks to the high speed the BUF works fast on large work surfaces. No backup pad is needed. Recommended applications: Deburring, Cleaning, Blending and Finishing and polishing of a wide range of parts. Work surfaces: Any kind of metal (stainless steel, titanium, aluminium, alloys), plastic and composite.

Request for a quoteResults for

Stainless steel alloys - Import exportNumber of results

35 ProductsCountries

Company type