- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure equipment

Results for

Pressure equipment - Import export

MIX SRL

Italy

Properties • no screws, pull-in sleeves or stiffeners in contact with the product on which the product can deposit • all parts that come into contact with the product are suitable for contact with food • continuously welded seams • hinged, lateral inspection hatch, which closes practically without dead space, with replaceable and washable seal • parts in contact with the product made of stainless steel with material certificate 3.1 according to EN 10204 • available for applications in positive or negative pressure or equipped with a fan

Request for a quote

MARTIN GROUP SRL

Italy

Electronic control of whole equipment high pressure (till 5kg./cmq.) which guarantees a very quality even for heavier productions two work plans to avoid downtime

Request for a quote

MARTIN GROUP SRL

Italy

equipped with back exit belt for retrieving adhesived fabric double heating system with preheating that allows to fuse using temperatures slightly below average “sandwich” also excellent for the most delicate fabrics pressure system with selector of the “OUT” device that allows to thermoadhesive the most delicate fabrics at zero pressure EQUIPPED WITH RETURN BELT: IT ALLOWS TO COLLECT THE FUSED FABRICS IN THE FRONT PART OF THE MACHINE. STACKER MOD. MODULAR SC 2000 - The continuos fusing machines need a fabric retrieval thtough a perfect alignment of the thermoadhesived pieces. The series “OPEN TOP PLER” has been carried out for the rationalization and the implementation of productivity. thoroughly automatic electronic stacker transport with linear rails the stackers are available with 1/2/3/4 discharge tracks function management carried out by PLC full reliability with any fabric counting device of adhesived items on each discharge track instrumental diagnostics on the touch sceens

Request for a quote

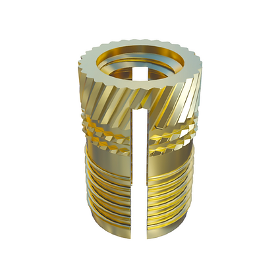

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The PRESS-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoplastic materials The combination of flat and knurled areas ensure high torque and pull out performance normally achievable only with inserts that are installed by a hot/ultrasonic process These inserts are installed by simple pressure, without need for special equipment Also known as PRESS-LOK, with equivalent shape, features and dimensions

Request for a quote

TAMA AERNOVA SRL

Italy

Data sheet Non-closable venting panel that with a pressing break opens itself letting the area completely free. The opening takes place thanks to the carvings breakage and relative “extraction” of the panel from its gasket. The plastic hinge guarantees that the panel remains opened without any projection of panel or counter-frame parts. This type of safety device is intended for protection from possible explosions, caused by a sudden pressure increase of equipments containing air/dust mixtures or gas/air potentially explosive mixtures such as silos, separator filters, bucket elevators, sieves, mixers, tanks, canals and pipelines, dust collectors, dryers, etc. All panels are breaking and safety devices and have been certified in accordance with UNI EN 14797: 2007. Opening efficiency: Ratio between the relief and the total area. Relief area: Area of the supposed venting device which is free from inertia. It shows the same effects of pressure reduction of the real device. Kst...

Request for a quote

TAMA AERNOVA SRL

Italy

Data sheet Non-closable venting panel that with a pressing break opens itself letting the area completely free. The opening takes place thanks to the carvings breakage and relative “extraction” of the panel from its gasket. The plastic hinge guarantees that the panel remains opened without any projection of panel or counter-frame parts. This type of safety device is intended for protection from possible explosions, caused by a sudden pressure increase of equipments containing air/dust mixtures or gas/air potentially explosive mixtures such as silos, separator filters, bucket elevators, sieves, mixers, tanks, canals and pipelines, dust collectors, dryers, etc. All panels are breaking and safety devices and have been certified in accordance with UNI EN 14797: 2007. Opening efficiency: Ratio between the relief and the total area. Relief area: Area of the supposed venting device which is free from inertia. It shows the same effects of pressure reduction of the real device. Kst...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pressure equipment - Import exportNumber of results

6 ProductsCountries

Company type