- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metric threading

Results for

Metric threading - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

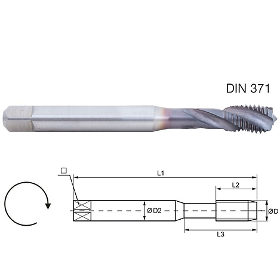

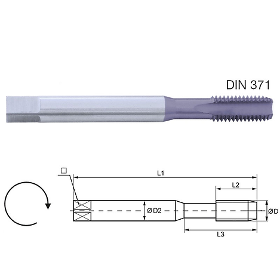

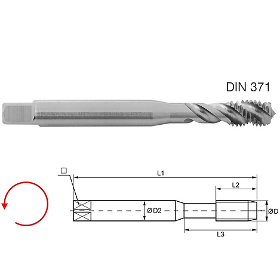

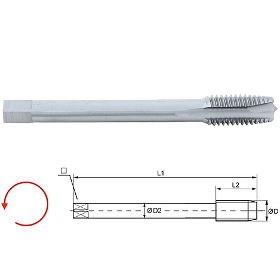

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Nickel-based superalloys Incoloy 825, Inconel 718, Nimonic 75, Hastelloy X

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Metric helicoidal thread inserts in stainless steel (helicoils) Reinforce the thread in low shear strength materials, such as aluminum, aluminum alloys, etc. Allow to restore a damaged thread to its initial size, ensure extremely reduced intervention time The reduced diameter of the first turn ensures that the thread insert can be placed into a hole like a regular screw For installation you may use taps and tools available in this sections: Thread insert taps, Installation tools for thread inserts Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Metric helicoidal thread inserts in stainless steel (helicoils) with screw lock Reinforce the thread in low shear strength materials, such as aluminum, aluminum alloys, etc. The self-locking thread insert is identical in construction and operating principle to the regular helical thread insert, but it also offers a braking action on the screw thanks to the particular polygonal configuration of one or more turns of the insert thread. In this way, the screw remains tightened with absolute reliability even in the presence of vibrations or shocks. The anti-unscrewing braking action remains even after numerous screwing and unscrewing operations The self-locking thread allows you to eliminate the use of other locking elements, such as elastic washers or similar, remaining effective even in the presence of high temperatures For installation you may use taps and tools available in this sections: Thread insert taps, Installation tools for thread inserts Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The single size metric Thread repair kit contains 1 finishing thread insert tap, 1 installation tool and between 5 and 15 thread inserts (see attached sheet) of the standard length 1.5D times the diameter. All contained in a practical plastic case, easy to store and transport Our thread repair kit is one of the most professional helicoil kits on the market. The installation tool is equipped with a threaded nose to prepare the helicoil thread insert to the size of the thread, making installation simple and safe Excellent choice for repairing damaged, span and worn threads in steel, iron, aluminum, alluminium alloys and hard plastic materials Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Helicoil finishing HSSE tap for metric thread inserts. For manual use and use in through holes Complies with DIN 81402 It is the most popular Helicoil STI tap, as in many cases it can be used without the need for roughing and bottoming taps. It also included in our Thread repair kits For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The tool for fast installation of large numbers of generally used small diameter Helicoil thread inserts It is the threaded spindle, that can be used manually or with any eletric scrwedriver. We suggest the Spiralock cordless programmable screwdriver, available in our catalog The threaded spindle guides the thread insert to the established depth, limited by the special ring Attention, this tool is not suitable for mounting DIN standard thread inserts, only those with a reduced diameter Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The single size installation tool for metric helicoil thread inserts designed for manual use. Can be used for installation of all types of thread inserts, including those complying with DIN 8140, used in the aeronautics and automotive, and also those with a reduced diameter for general use Specially designed for thread inserts of smaller sizes M2 - M4 It has a threaded nose and rod so that the thread when inserted will be guided internally by the thread of the rod and externally by the thread of the nose before and a little bit after This installation tool prevents deformation of thread insert even if the operator exerts too much pressure, ensuring easy and safe installation Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The single size installation tool for metric helicoil thread inserts designed for manual use. Allows the installation of all types of thread inserts, including those complying with DIN 8140, used in the aeronautics and automotive, and also those with a reduced diameter for general use It is the most popular installation tool, the same contained in the Thread Repair Kits The threaded nose prepares the helicoil thread insert to the size of the thread, making installation simple and safe. It also allows installation in difficult areas, without use of the other hand to hold the insert Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The Thread repair kit 4 diameters includes the most popular sizes in the various pitches available (see data sheet). For each of the four diameters the kit contains 1 finishing thread insert tap, 1 installation tool, 1 cutter and 15 thread inserts. All contained in a practical plastic case, easy to store and transport Our thread repair kit is one of the most professional helicoil kits on the market. The installation tool is equipped with a threaded nose to prepare the helicoil thread insert to the size of the thread, making installation simple and safe Excellent choice for repairing damaged, span and worn threads in steel, iron, aluminum, alluminium alloys and hard plastic materials Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Type H Helicoil HSSE tap for metric thread inserts. Compatible with all types of helicoidal thread inserts For blind holes and manual or machine use. Spiral flutes of the tap extract chips from blind holes which allows to avoid stuffing Complies with DIN 81402 For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

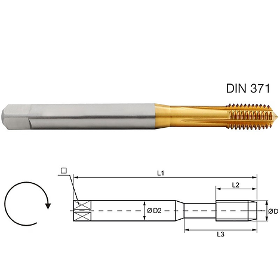

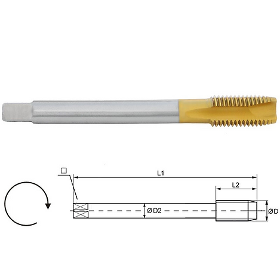

Thread standard: Metric, ISO DIN 13 Type: Machine forming tap Application: General use Material of product: HSSE Surface treatment: TIN For materials: Steel, Stainless steel, Cast aluminum, Coper, Brass etc* Tensile strength up to: 850 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6HX The Forming tap has improved geometry for an optimal processing of a big range of materials. The lubrication grooves provide the necessary lubrication to depths of 2.5 D. Advantages: no chips up to 20 times longer lifetime (compared to taps) same forming tap for through hole and blind hole wide range of materials can be processed intersection of the thread is impossible no pitch or flank angle errors increased strength of the thread through material deformation higher surface quality much higher cutting speed Please be aware to reach enough cutting speed, so that the material can optimally plasticized. Only for machine use.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

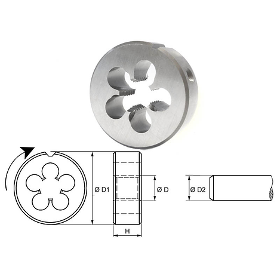

Thread standard: Metric, ISO DIN 13 Type: Round die Application: For stainless steel Material of product: HSSE Spiral entry: yes For materials: Stainless steel (INOX, V2A, V4A etc.) Tensile strength up to: 1200 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Special geometry for Stainless steel. Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

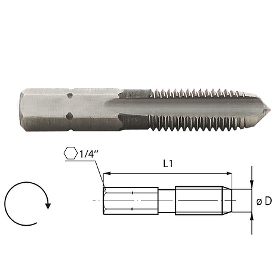

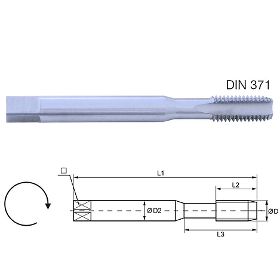

Thread standard: Metric, ISO DIN 13 Type: Machine bit tap Form D, for through and blind holes Application: General use Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: Factory standard Tolerance: ISO2/6H Bit taps have been designed for thread cutting using battery-powered screwdriver drills and electric hand drills with right-hand and left-hand rotation. But they are also suitable for thread cutting by hand or in a stationary drilling machine. Your battery-powered screwdriver drill should have a minimum power of 7.5 Volts. Take care that the tool and the axis of the hole are exactly aligned and use a suitable cutting oil. For thread cutting we recommend using battery-powered screwdriver drills and electric hand drills with lowest rotaionsettings (0 - 450 RPM) and maximum torque settings.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

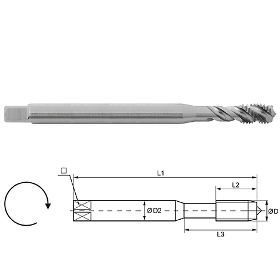

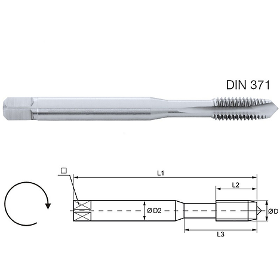

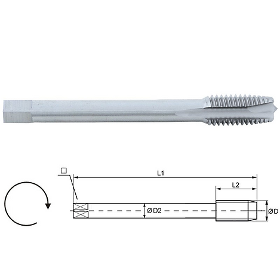

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Overlengthed (long shank) L=100 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

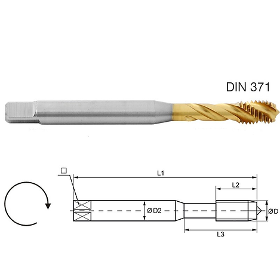

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For cast materials Material of product: HSSE Surface treatment: TiCN For materials: Grey cast iron, Aluminium casting alloy, Copper base alloys etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for short-chipping casting material. The TiCN surface treatment (titanium carbon nitride - grey violet) increases the surface hardness (approx. 3000 HV) and the sliding properties (coefficient of friction: 0,3). It provides a better cutting performance and increased tool life time. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Materials: Grey cast iron < 1000 N/mm² Aluminium casting alloy Si > 5% (short-chipping) up to 600 N/mm²

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

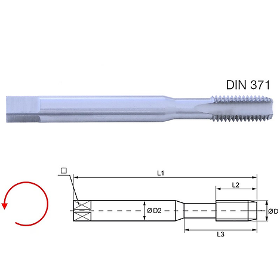

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: Left-hand Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Round die Application: General use Material of product: HSS Spiral entry: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 750 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Oversized diameter 6G Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO3/6G Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Tolerance ISO3/6G – Thread with large clearance. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For brass Material of product: HSSE Surface treatment: TIN For materials: Brass (short chipping) Tensile strength up to: 600 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Due the cutting geometry specially recommended for applications in Copper-zinc alloy (Brass) - short-chipping. Tap for machine use in blind and through holes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Left-hand Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Round die Application: d25x9 Material of product: HSS Spiral entry: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 750 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Left-hand Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materialsCorrect lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants. Brand: Baer Tools (Germany)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

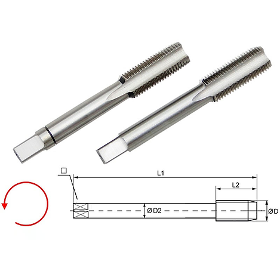

Thread standard: Metric Fine, ISO DIN 13 Type: Hand tap, Form C, for through and blind holes, with straight flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: no For materials: Wear resistant steel Tensile strength up to: 1000 N/mm2 Standard: DIN 2181 Tolerance: ISO2/6H Set of 2 taps (taper, finish). Two-piece hand taps- sets are used for fine threads with a smaller pitch than with coarse thread, as the thread profile surface is smaller than with coarse threads and the force effects on the taps are smaller. The advantage of two-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) (marked with a ring) removes 65 per cent of the thread profile and the and brings the thread into shape. The finishing tap (No. 3) has no ring marking and cuts the remaining thread profile to produce the 100% full and usable thread.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

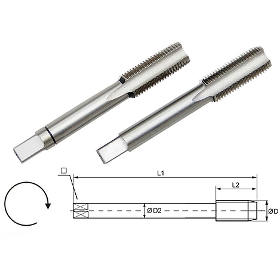

Thread standard: Metric Fine, ISO DIN 13 Type: Hand tap, Form C, for through and blind holes, with straight flutes Application: Left-hand Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 2181 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Set of 2 taps (taper, finish). Two-piece hand taps- sets are used for fine threads with a smaller pitch than with coarse thread, as the thread profile surface is smaller than with coarse threads and the force effects on the taps are smaller. The advantage of two-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) (marked with a ring) removes 65 per cent of the thread profile and the and brings the thread into shape. The finishing tap (No. 3) has no ring marking and cuts the remaining thread profile to produce the 100% full and usable thread.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Hand tap, Form C, for through and blind holes, with straight flutes Application: General use Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 2181 Tolerance: ISO2/6H Set of 2 taps (taper, finish). Two-piece hand taps- sets are used for fine threads with a smaller pitch than with coarse thread, as the thread profile surface is smaller than with coarse threads and the force effects on the taps are smaller. The advantage of two-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) (marked with a ring) removes 65 per cent of the thread profile and the and brings the thread into shape. The finishing tap (No. 3) has no ring marking and cuts the remaining thread profile to produce the 100% full and usable thread.

Request for a quoteResults for

Metric threading - Import exportNumber of results

73 ProductsCountries

Company type

Category