- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal treatments

Results for

Metal treatments - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

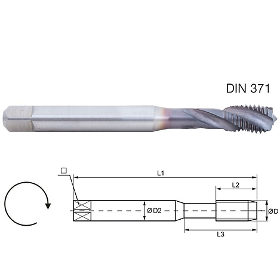

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Nickel-based superalloys Incoloy 825, Inconel 718, Nimonic 75, Hastelloy X

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

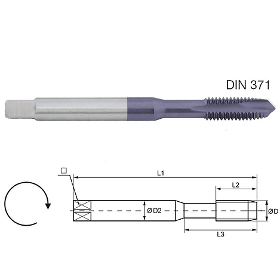

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The self-clinching stud is the modern and rational alternative to the weld-on stud. The stud is easily applied to metal sheets of various thicknesses creating a secure, unequaled-looking attachment with very high strength values. There is almost no damage to the surface of the sheet metal and its treatment This self-clinching stud is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch, applyinng only sufficient pressure to squeeze the stud head and its under head tooth features into the parent sheet. The sheet metal experiences plastic deformation and locks the fastener firmly to itself. After installation the spigot joint should be flush with the sheet, so the result is aesthetically perfect. And the tooth locking feature provides high tensile as well as torsional strength

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A.’s forging and heattreatment division is capable of forging fittings (in a closed die) up to 4” 16 kg. The heat treatment furnaces and tanks are all certified to Norsok M650 and ASTM A991 standards and can treat any product that M.E.G.A. produces (large and small forgings, pipes and any other type of part).

Request for a quote

PEROZENI SRL

Italy

The quality of the welded structures is guaranteed by non-destructive tests carried out on request by our qualified in-house personnel or by certified external organizations. We also perform dimensional tests that, on the basis of the precision required, are made using calibers, micrometers or the special tool “FARO Cam2 Laser Tracker Vantage”. Other types of processing can also be handled by us, such as distension heat treatment, metallic galvanization, chrome plating and other treatments, through our partnership with qualified suppliers with whom we have established advantageous collaboration for many years.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SEIT ELETTRONICA SRL

Italy

IMPROVE YOUR HEATING PROCESS PLATINUM MF Series is the new range of Medium-Low Frequency Induction Generators, ideal for all heating automatic or manual processes. With the MF generators, you have a total control of the heating process and you get high quality results. MF generators guarantee you repetitiveness and precision in reduced time. CHARACTERISTIC Model: Platinum MF5 - 10 - 15 - 25 Output power (kW): 5kW - 10kW - 15kW - 25kW Duty Cycle: 100% Frequency range: 15 kHz -55 kHz Output power regulation: 10 - 100% Power supply: 400V - 3ph - 50/60Hz Cooling: H2O demineralized FEATURES - Touch-screen display 7” - Digital control of all functions - Creation and saving of multistep programs - Heating profiles based on temperature and / or power - USB connection - Multilingual user interface

Request for a quoteResults for

Metal treatments - Import exportNumber of results

7 ProductsCompany type