- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- alloy cast iron

Results for

Alloy cast iron - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

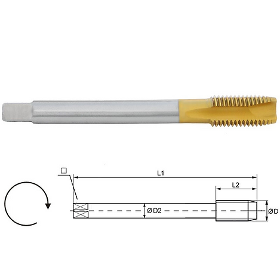

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance Long version with three cutting holes, Ensat 308 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Similar to Ensat 307 but longer, so can be applied in thicker materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel Short version with three cutting holes, Ensat 307 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Also Ensat 307 inserts are shorter than Ensat 308 and therefore ideal on thinner materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance Short version with three cutting holes, Ensat 307 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Also Ensat 307 inserts are shorter than Ensat 308 and therefore ideal on thinner materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality brass self-tapping ensat thread inserts. Particularly suitable for light metals and all types of plastics, both thermoplastics and thermosets This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

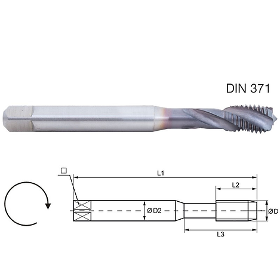

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1400 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

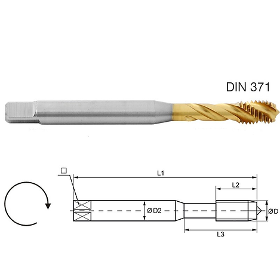

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

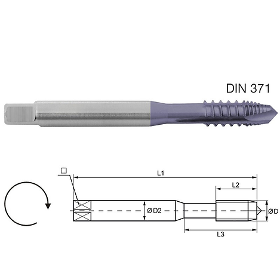

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For aluminium Material of product: HSSE Surface treatment: TiAlN For materials: Pure Aluminium, Aluminium cast and wrought alloys, Soft iron etc* Tensile strength up to: 700 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for light alloys (Aluminium, Copper, etc). The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Soft Iron Pure Aluminium, Aluminium cast and wrought alloys Si<5% (long-chipping) Pure Copper, Copper alloys and copper-zinc alloys (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Keensert high-strength threaded inserts enter in pre-threaded holes and are secured via their locking keys. In High duty series they have 2 or 4 locking keys (depending from diameter) which once positioned make the insert mechanically locked against unscrewing from rotation or vibrations. Keenserts are extremely robust, have high resistance to rotation and extraction, a very precise thread and are easy to install and remove. They are widely used in sectors such as mechanics or precision engineering, aeronautics and aerospace on light alloys, steel or cast iron. They can also be used in damaged threads in expensive components. The Keensert inserts are supplied with the locking keys already positioned inside the grooves. The pre-positioned keys ensure that by screwing the insert it automatically positions itself at the correct installation depth. Keenserts are installed using special Keenest installation tool.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Keensert high-strength threaded inserts enter in pre-threaded holes and are secured via their locking keys. In Light duty series they have 2 or 4 locking keys(depending from diameter) which once positioned make the insert mechanically locked against unscrewing from rotation or vibrations. Keenserts are extremely robust, have high resistance to rotation and extraction, a very precise thread and are easy to install and remove. They are widely used in sectors such as mechanics or precision engineering, aeronautics and aerospace on light alloys, steel or cast iron. They can also be used in damaged threads in expensive components. The Keensert inserts are supplied with the locking keys already positioned inside the grooves. The pre-positioned keys ensure that by screwing the insert it automatically positions itself at the correct installation depth. Keenserts are installed using special Keenest installation tool. As standard, Keenserts in LIGHT duty series are supplied in:

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Keensert high-strength threaded inserts enter in pre-threaded holes and are secured via their locking keys. In Micro series they have 2 locking keys which once positioned make the insert mechanically locked against unscrewing from rotation or vibrations. Keenserts are extremely robust, have high resistance to rotation and extraction, a very precise thread and are easy to install and remove. They are widely used in sectors such as mechanics or precision engineering, aeronautics and aerospace on light alloys, steel or cast iron. They can also be used in damaged threads in expensive components. The Keensert inserts are supplied with the locking keys already positioned inside the grooves. The pre-positioned keys ensure that by screwing the insert it automatically positions itself at the correct installation depth. Keenserts are installed using special Keenest installation tool. As standard, Keenserts in MICRO series are

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIBIELLE S.P.A.

Italy

These are similar to the Satin Machine wheels but are made laying the non woven in a way that waved edges are obtained. Features and benefits: For applications on wide areas which require a higher uniformity finishing, the RFV allow a higher uniformity among the various steps on the surface. Recommended applications: Satin finishing large surfaces. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminum, cast iron, titanium, plastic.

Request for a quote

BIBIELLE S.P.A.

Italy

Y-weight polyester backing, Zirconium grain with cooling additive, double resin, closecoat. Main features and benefits: This product is particularly suitable for applications requiring highly efficient removal, extremely quick cutting performance and low operating temperature. This product can be supplied in customised sizes. Recommended applications: Deburring, removing protruding welded surfaces and excess material, removing scale. Work surfaces: Stainless steel, alloyed steel, aluminium, cast iron.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide bands to be used (with suitable expanders) on satin finish machines. Main features and benefits: Thanks to their wide abrasive area, they allow operators to rapidly and efficiently work on a wide range of surfaces. Recommended applications: Light deburring, cleaning, finishing small and large surfaces. Removing scale or marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, wood.

Request for a quote

BIBIELLE S.P.A.

Italy

Economic version of the flap discs. Available in back up pad discs and fiberglass version. Features and benefits: These discs offer good cutting and have a good ratio cost/performance. These are particularly suitable for non continuous processing where cutting speed and costs are the main elements. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium, plastic, pain, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

Economic version of the flap discs. Available in back up pad discs and fiberglass version. Features and benefits: These discs offer good cutting and have a good ratio cost/performance. These are particularly suitable for non continuous processing where cutting speed and costs are the main elements. Recommended applications: Deburring, removing welding seams and spots, removing scale, rust and oxidation of any kind, blunting sharp corners and edges. Work surfaces: Stainless steel, alloyed and unalloyed steel, aluminum, nonferrous metals and alloys, structural steel, cast iron, titanium, plastic, pain, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

This High Performance Nonwoven and cloth material is converted into wheels with a split pin hole for satin finish machines. Main features and benefits: These wheels offer better cutting performance than nonwoven wheels whilst ensuring high finishing quality and excellent user friendliness combined with highly efficient ventilation and low-noise levels typical of nonwoven products. Thanks to a unique 4-split-pin system, the abrasive tool can be efficiently driven and quickly fit. Recommended applications: Light deburring and cleaning. Satin finishing small and large surfaces. Removing scale. Removing marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium.

Request for a quote

BIBIELLE S.P.A.

Italy

This High Performance Nonwoven material is converted into wheels with a split pin hole for satin finish machines. Main features and benefits: These nonwoven wheels with a hole offer consistent finishing quality, highly efficient ventilation, flexibility, excellent user friendliness, low-noise levels and resistance to clogging. They can be cleaned using compressed air or water. The abrasive tool is efficiently driven by means of a unique 4-split-pin system and can be quickly fit. Recommended applications: Light deburring and cleaning. Satin finishing small and large surfaces. Removing scale. Removing marks left by previous operations and re-finishing after bending, welding or satin coil moulding. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic.

Request for a quote

BIBIELLE S.P.A.

Italy

BIBIELLE offers a very good satin finish machine, particularly suitable to be used with the provided abrasive tools. Main features and benefits: The abrasive tools for satin finish machines allow operators to work on quite large areas (from 50 to 100 mm in width) with a lightweight compact machine that can be used “freehand” even on parts already in place. The abrasive tool is efficiently driven by means of a unique split pin system. Recommended applications: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, paint, varnish, filler, stone or wood. Work surfaces: Production and maintenance of machinery and equipment for the chemical, pharmaceutical, medical and food industries. Steel and stainless steel fittings such as cookers, extractor hoods, hobs and domestic appliances.

Request for a quote

BIBIELLE S.P.A.

Italy

This Silicon Carbide High Performance Nonwoven material is converted into discs with hole. Main features and benefits: Discs can be assembled to reach the desired size. Depending on the pressure used for assembling the discs it is also possible to vary the hardness. These pre-cut nonwoven discs offer consistent finishing quality, highly efficient ventilation, flexibility, excellent user friendliness, low-noise levels and resistance to clogging. Can be cleaned using compressed air or water. Recommended applications: Cleaning parts of irregular shape or moulded parts. Satin finishing small and large surfaces. Workpiece preparation for subsequent treatments such as chromium plating, nickel plating and painting. Removing marks left by previous operations and re-finishing after bending, welding or satin coil moulding. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, paint, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

This Aluminium Oxide High Performance Nonwoven material is converted into discs with hole. Main features and benefits: Discs can be assembled to reach the desired size. Depending on the pressure used for assembling the discs it is also possible to vary the hardness. These pre-cut nonwoven discs offer consistent finishing quality, highly efficient ventilation, flexibility, excellent user friendliness, low-noise levels and resistance to clogging. Can be cleaned using compressed air or water. Recommended applications: Cleaning parts of irregular shape or moulded parts. Satin finishing small and large surfaces. Workpiece preparation for subsequent treatments such as chromium plating, nickel plating and painting. Removing marks left by previous operations and re-finishing after bending, welding or satin coil moulding. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, paint, varnish, filler.

Request for a quote

BIBIELLE S.P.A.

Italy

These wheels on 6-mm shaft are made of a combination of cloth flaps and High Performance Nonwoven material. To be used on straight grinders. Main features and benefits: Thanks to the abrasive cloth the scrubbing action of BIBIELLE shaft-mounted nonwoven wheels is more aggresive whilst ensuring high finishing quality, excellent user friendliness combined with highly efficient ventilation and low-noise levels typical of nonwoven products. Recommended applications: Light deburring and cleaning parts of irregular shape, pipes or moulded parts. Removing scale. Removing marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium.

Request for a quote

BIBIELLE S.P.A.

Italy

This High Performance Nonwoven material is converted into wheels on 6-mm shaft to be used on straight grinders. Main features and benefits: These shaft-mounted Nonwoven wheels offer consistent finishing quality, excellent user friendliness, highly efficient ventilation, low-noise levels, resistance to clogging. Recommended applications: Light deburring and cleaning parts of irregular shape, pipes or moulded parts. Satin finishing small surfaces. Removing scale. Removing marks left by previous operations and re-finishing after bending, welding or satin coil moulding. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic.

Request for a quoteResults for

Alloy cast iron - Import exportNumber of results

38 ProductsCompany type

Category