- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high alloy steel

Results for

High alloy steel - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Round die. Metric, ISO DIN 13. HSSE. DIN 223. Tolerance ISO-6g. For high-tensile materials. Up to 1200 N/mm2. Professional thread cutting Thread standard: Metric, ISO DIN 13 Type: Round die Application: For high-tensile materials Material of product: HSSE Spiral entry: yes For materials: Tensile strength up to: 1200 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Special geometry for high-strength material. Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

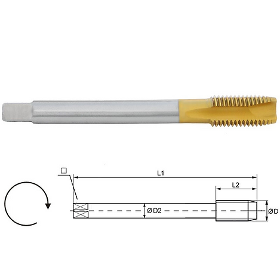

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

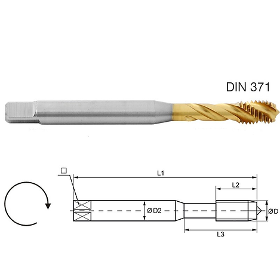

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

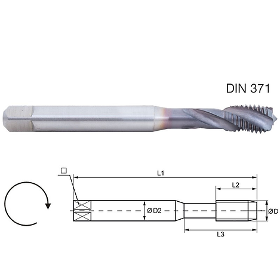

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Our high-performance cutting paste in the practical 100ml pack is characterised by particularly high pressure additives that achieve a very high lubrication performance. The paste adheres firmly to the cutting edges and only becomes liquid during use. For optimum results, the cutting paste should be applied undiluted. This cutting paste is ideal for many machining operations such as drilling, thread cutting, thread cutting, milling, core drilling and sawing. It is suitable for all types of steel - from iron and tool steel to high-alloy steels and chrome-nickel alloys to aluminium, titanium, manganese, cast steel, grey cast iron, brass, bronze and all stainless steels V2A, V4A, INOX etc. Due to the environmentally friendly, petroleum-free, chlorine-free and sulphur-free formulation, the high-performance cutting paste not only offers longer tool life, but also leaves no greasy oil film on the workpieces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1400 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

PRAGMA BUYING SRLS

Italy

THE AC ELECTRIC ARC FURNACE (EAF) FROM STS IS THE IDEAL MELTING UNIT FOR THE PRODUCTION OF ALL TYPES OF STEEL, FROM STANDARD CARBON GRADES TO HIGH-ALLOYED AND STAINLESS STEEL GRADES. Its overall furnace performance can be additionally enhanced with the latest oxygen- and carbon-injection technologies. has fully developed his own technology in EAF. Melting process is controlled by STS high performance Electrodes regulation system MAIN DESIGN FEATURES Split Type Design Furnace Shell, Replaceable type for minimum relining downtime. Eccentric Bottom Tapping Type (EBT ). Current Conducting Electrode Arms. Furnace movements and electrode arm hydraulically actuated. Inert gas bottom purging facilities. Automatic Feeding Of DRI.

Request for a quoteResults for

High alloy steel - Import exportNumber of results

9 ProductsCompany type