- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating installations

Results for

Heating installations - Import export

FERPLAST SNC

Italy

PROFESSIONAL GLUE GUNS SERIES M The professional glue guns series M are suitable for assembling, gluing, repairs on wood, plastic, cardboard, paper, cloth, metal pre-heated, rubber and leather. Installation and repair of tiles and porcelain. The M 812 model is recommended for intensive industrial use and is also available in the motorized M 812MG version with automatic continuous extrusion glue advancement device. FEATURES - Max. extrusion glue: 800 - 1200 - 1500 -1800 g/h approx. - Max. operating temperature: 190-220-230°C - Adjustment of the temperature and the extrusion capacity (excluding mod. M 195) - Support bracket and interchangeable, insulated and antidrop nozzle - Packaging: In a sturdy plastic carrying case complete with spare nozzle - Uses 12 mm diameter glue sticks, length 200 mm.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S14 (Short version) are inserts for plastic with heat/ultrasonic installation into tapered holes with an 8° angle In the short version these inserts offer the advantage of having reduced dimensions, shorter installation times and lower costs. On the other hand, the resistance to torque and pull out loads is reduced comparing to long version Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The tapered form facilitates proper seating and maximizes the surface contact between the insert and hole wall prior to the application of heat or ultrasonic vibration. These inserts are the best choice when using ultrasonic insertion techniques The insert's straight-toothed upper ring and oblique-toothed middle ring provide high torque and pull out resistance, ensuring complete filling of the plastic material in the cavities below Installation must be carried out using heat conduction or ultrasonic machines.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The SONIC-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics They are designed for quick and economical installation Opposing knurls of the insert offer high torque and pull out performance Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Also known as SONIC-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

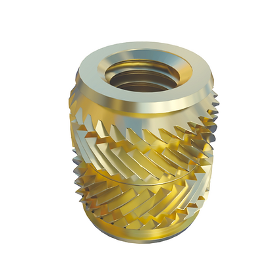

The HEAT-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics Designed for installation in notch-sensitive amorphous thermoplastic materials. The rounded knurling reduces stress on the contact surface while avoiding stress on the material in which it is inserted Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet They are available in unheaded and headed (flanged) versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. Also a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications Unheaded inserts in addition are symmetrical so they do not need to be oriented during installation process

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

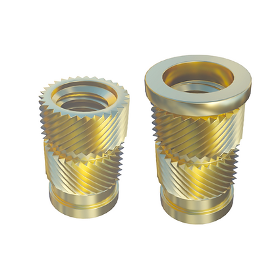

The TECH-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics They feature a unique combination of helical knurls with opposite directions and knurled flanges, which substantially increase torque and pull-out resistance, even compared to the SONIC-SERT inserts Installation is simplified by the symmetrical nature of the insert, eliminating the need for orientation during automated or manual feeding Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Also known as TECH-SONIC, with equivalent shape, features and dimensions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S29, S30 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S29, S30 inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates These inserts were designed to provide faster speed and ease of installation, and at the same time maximize torque and pull out performance. The outer profile was made symmetrical with respect to length, so that the insert does not have to be oriented during the installation process. These inserts are therefore suitable for automatic type installations in large volume The S29, S30 offer much higher torque and pull-out resistance than all other inserts Holes sizes are identical to those of the S19 and S20 inserts to provide an easy alternative

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S19, S20 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S19, S20 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The S19, S20 inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance They induce very low radial stresses and are therefore particularly recommended in holes with thin walls. In this case the hole must be a bit wider. Optimal size should be determined after appropriate practical tests Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S14 (Long version) are inserts for plastic with heat/ultrasonic installation into tapered holes with an 8° angle These are the longer versions of the S14 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The tapered form facilitates proper seating and maximizes the surface contact between the insert and hole wall prior to the application of heat or ultrasonic vibration. These inserts are the best choice when using ultrasonic insertion techniques The insert's straight-toothed upper ring and oblique-toothed middle ring provide high torque and pull out resistance, ensuring complete filling of the plastic material in the cavities below Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Inch version from 2-56 to 5/16-18 is available upon request

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S19, S20 (Short version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes In the short version these inserts offer the advantage of having reduced dimensions, shorter installation times and lower costs. On the other hand, the resistance to torque and pull out loads is reduced comparing to long version Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The S19, S20 inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance They induce very low radial stresses and are therefore particularly recommended in holes with thin walls. In this case the hole must be a bit wider. Optimal size should be determined after appropriate practical tests Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet

Request for a quote

CRE VERZENI COMPANY

Italy

C.R.E. di Verzeni is a certified firm, leader in the production of heating elements for over 50 years. Our experience and skills allow us to establish not only in the Italian market, but also worldwide. Thanks to the purchasing of new machinery technology we have increased our quality standards while reducing production costs. This guarantees our clients, quality at competitive prices. We are official distributors for the main machinery manufacturers of: •Plastic, rubber (press, blow, extrusion, injection etc.) •Chemical/Pharmaceutical •Food (dryers and mixers) •Packaging •Water sector •Etc. C.R.E. di Verzeni is characterized by: One of the best quality on the European market--we got UNI EN ISO 9001-2000 certification Italian design with customized products Good quality/price ratio Fully made in ItalyProduction times: 7 days after your order and if urgent up to 24hours after the order (depends on the type of heater). On our website www.creverzeni.com

Request for a quoteResults for

Heating installations - Import exportNumber of results

11 ProductsCompany type