- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hard surfacing

Results for

Hard surfacing - Import export

OR.P. STAMPI SRL

Italy

Chrome Plating Shiny / Opaque surface finish An electroplating process whereby chrome is deposited “on and below” the surface of the mould. Different types of chroming procedures may take place, depending on type of compound to be used, and aspect/use of the moulded part. Facilitated compound flow Easier demoulding Reduced frequent mould cleaning Longer mould life

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

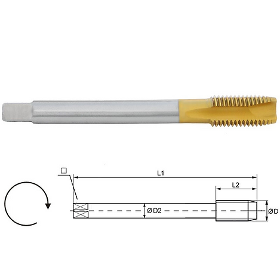

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

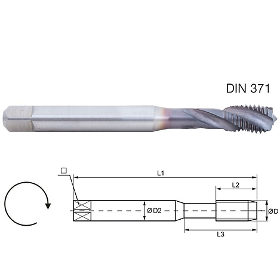

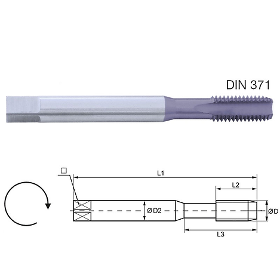

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Nickel-based superalloys Incoloy 825, Inconel 718, Nimonic 75, Hastelloy X

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

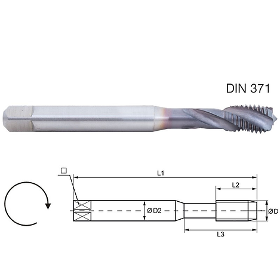

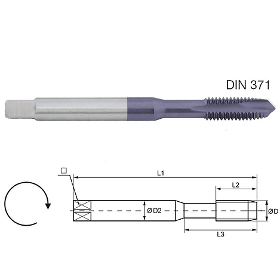

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1400 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

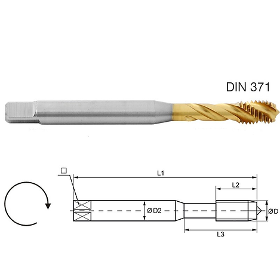

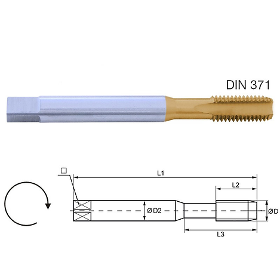

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For cast materials Material of product: HSSE Surface treatment: TiCN For materials: Grey cast iron, Aluminium casting alloy, Copper base alloys etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for short-chipping casting material. The TiCN surface treatment (titanium carbon nitride - grey violet) increases the surface hardness (approx. 3000 HV) and the sliding properties (coefficient of friction: 0,3). It provides a better cutting performance and increased tool life time. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Materials: Grey cast iron < 1000 N/mm² Aluminium casting alloy Si > 5% (short-chipping) up to 600 N/mm²

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: General use (long-life version) Material of product: HSSE Surface treatment: TIN For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For aluminium Material of product: HSSE Surface treatment: TiAlN For materials: Pure Aluminium, Aluminium cast and wrought alloys, Soft iron etc* Tensile strength up to: 700 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for light alloys (Aluminium, Copper, etc). The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Soft Iron Pure Aluminium, Aluminium cast and wrought alloys Si<5% (long-chipping) Pure Copper, Copper alloys and copper-zinc alloys (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

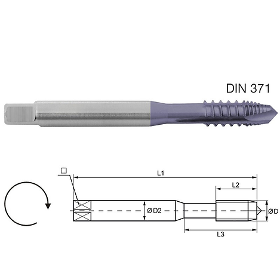

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

CASEARTECNICA BARTOLI SRL

Italy

Suitable for handling shapes weighing up to 100 kg, in any place and environment. 21/02/2024, 18:12 Bartoli | Attrezzature per la produzione del formaggio https://www.caseartecnicabartoli.it/en/attrezzaturaproduzioneformaggio 5/6 They are equipped with a resistant stainless steel structure that makes them highly stable and an ergonomic shape that allows them to be moved anywhere, without any effort. They are supplied with battery and charger. Main features: Particularly solid structure, entirely in stainless steel. Electric devices for starting and stopping, controlled by software, located in the central body. Dc engine. Dry-type battery without maintenance. Battery charger with automatic removal when fully charged. Up / down control push-button panel. Battery charge display. Ergonomic handle. Loading surface in hard, non-deformable plastic. Small size. Handy and easy to manage. Pivoting rubber wheels. The rear wheels are equipped with a parking brake.

Request for a quote

LUCEDENTRO SRL

Italy

The photoluminescent paint Lucedentro was born for those costumers who want to take advantage from a photoluminescent product whose characteristic is the ultimately simplicity and the wide range of applications. The product, which has the luminous power of photoluminesce, has been realized to work on hard surfaces, figuring an application on indoors and outdoors, but Lucedentro keep it highly customizable on specific request.

BIBIELLE S.P.A.

Italy

Aluminium oxide flaps and X-Flex weight backing. 6-mm diameter cylindrical shaft. Main features and benefits: These wheels are our most versatile RG tools. Robust and suitable for numerous applications on work surfaces of various kinds. Excellent flexibility. Recommended applications: Finishing, light deburring, cleaning or preparation for subsequent treatments (chromium plating, nickel plating or painting) on small or hard-toreach surfaces such as the internal surfaces of pipes, cylinders, parts of irregular shape. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre, rubber, marble, stone, concrete, wood, hide or leather

Request for a quoteResults for

Hard surfacing - Import exportNumber of results

16 ProductsCompany type