- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- finishing machines

Results for

Finishing machines - Import export

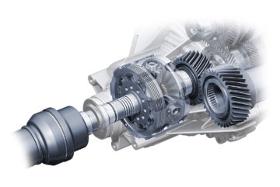

ITALGEAR SRL

Italy

The common roots shared with the Poppi Forging Industries provide ITALGEAR a facilitated access to the forging facilities of the Group and particularly the ability to source electrical upsetted parts with dimensions that are predetermined by specific software’s that allow minimizing the stock material hence resulting into superior quality and price effectiveness of the finished product. Gears of shafts and axle shafts, after their heat treatment, can also be finished with the use of the Skiving technology that makes use of specific hard metal hobbing tools that are PVD coated. The Skiving technology allows production of gears that combine a high quality finishing with reduced machining time and costs.

Request for a quote

CASEARTECNICA BARTOLI SRL

Italy

For the cutting of hard and semi-hard cheese we offer a wide range of semi-automatic portioning machines suitable for cutting all types of gifts, ranging from counter machines to automatic lines. The automatic lines are supplied to a large part of the Italian and foreign GDO. In particular: Automatic, semi-automatic and semi-manual cheese cutting machines. Portioning machines, which allow you to accurately divide the cheese into slices of customizable size. Horizontal disconnectors, which perform the horizontal cut of the shapes. Automatic cleaners, to eliminate the impurities present on the rind of aged cheeses before cutting and packaging. Automatic graters, which allow to obtain a homogeneous and ready-to-use finished product. Flattening machines, to precisely cut the upper and lower plate of the forms, for packaging.

Request for a quote

OFFICINA MASTER S.P.A

Italy

Non-stop equalizing used right after ramose, decatizing or other textile finishing machines for perfectly rolling with no tension. All machines has 2 processing zones: one divergent (conical =1mt) where fabric is raised to the desired width; the other parallel=0.5mt, where fabric is stabilized and rolled. Optional can be added 2 vaporizing trays to eliminate creases.

Request for a quote

BIBIELLE S.P.A.

Italy

BIBIELLE offers a very good satin finish machine, particularly suitable to be used with the provided abrasive tools. Main features and benefits: The abrasive tools for satin finish machines allow operators to work on quite large areas (from 50 to 100 mm in width) with a lightweight compact machine that can be used “freehand” even on parts already in place. The abrasive tool is efficiently driven by means of a unique split pin system. Recommended applications: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, paint, varnish, filler, stone or wood. Work surfaces: Production and maintenance of machinery and equipment for the chemical, pharmaceutical, medical and food industries. Steel and stainless steel fittings such as cookers, extractor hoods, hobs and domestic appliances.

Request for a quote

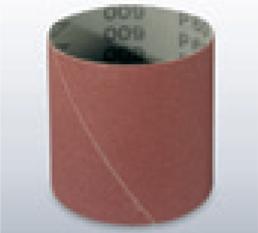

BIBIELLE S.P.A.

Italy

Aluminium oxide bands to be used (with suitable expanders) on satin finish machines. Main features and benefits: Thanks to their wide abrasive area, they allow operators to rapidly and efficiently work on a wide range of surfaces. Recommended applications: Light deburring, cleaning, finishing small and large surfaces. Removing scale or marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, wood.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIBIELLE S.P.A.

Italy

This High Performance Nonwoven and cloth material is converted into wheels with a split pin hole for satin finish machines. Main features and benefits: These wheels offer better cutting performance than nonwoven wheels whilst ensuring high finishing quality and excellent user friendliness combined with highly efficient ventilation and low-noise levels typical of nonwoven products. Thanks to a unique 4-split-pin system, the abrasive tool can be efficiently driven and quickly fit. Recommended applications: Light deburring and cleaning. Satin finishing small and large surfaces. Removing scale. Removing marks left by previous operations. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium.

Request for a quote

BIBIELLE S.P.A.

Italy

This High Performance Nonwoven material is converted into wheels with a split pin hole for satin finish machines. Main features and benefits: These nonwoven wheels with a hole offer consistent finishing quality, highly efficient ventilation, flexibility, excellent user friendliness, low-noise levels and resistance to clogging. They can be cleaned using compressed air or water. The abrasive tool is efficiently driven by means of a unique 4-split-pin system and can be quickly fit. Recommended applications: Light deburring and cleaning. Satin finishing small and large surfaces. Removing scale. Removing marks left by previous operations and re-finishing after bending, welding or satin coil moulding. Work surfaces: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic.

Request for a quote

BIBIELLE S.P.A.

Italy

BCW Metal Finish Convolute Wheels Main features and benefits: The dense and durable, but still open web and the strong resin allow uniform finishing but also light deburring operations without changing the dimesions of the workpiece. Long life, extremely consistent finishing, high stock removal, conformability to the worked piece and cool running. Recommended applications: Generates uniform distinct satin, cosmetic, brushed and antique finishes. Blend machine tool marks and apply final finish, blend coated abrasive scratches while applying a burr-free finish acceptable for coating and polishing in one step. Can be used for light deburring applications, removing discoloration from welds, general purpose cleaning, removing rust.

Request for a quoteResults for

Finishing machines - Import exportNumber of results

9 ProductsCompany type