- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- epoxy resins

Results for

Epoxy resins - Import export

OCV ITALIA

Italy

SE8400 Type 30™ singleend roving is specifically designed for pultrusion processing in applications requiring high electrical resistance. Produced with Advantex®, corrosionresistant ECR glass technology by Owens Corning. Compatible with polyester, vinyl ester and epoxy resins. EFFICIENT PROCESSING Better wetout in polyester, vinyl ester, and epoxy resin, offering fast processing and good glasstoresin bonding, resulting in optimized part production. Good wetout and resin bonding results in excellent visual appearance of parts produced. GOOD MECHANICAL PROPERTIES Low seed glass results in excellent dielectric properties which are ideal for applications requiring high electrical resistance. ADVANCED SERVICE LIFE Advantex® corrosion resistant glass fiber combined with low seed glass is ideal for longterm electrical, physical, and acid resistance, reducing the potential for costly brittle fracture failures in the field.

Request for a quote

COLLA 21

Italy

Adesivo EXTRA STRONG per incollaggi ad alta esistenza. Trasparente, universale e riempitivo. Il formato ideale per la casa e i tuoi hobby. LA BICOMPONENTE PER TUTTI! CON SIRINGA PER UN DOSAGGIO PERFETTO.

Request for a quote

LA MISOLET

Italy

The vetronites may contain epoxy, polyester, melamine and silicone resins with different thermal class depending on the model chosen. They have excellent mechanical and dielectric characteristics and are suitable for use in many sectors and are the excellence for the electromechanical sector. It should be noted that FR4, GPO3 and FR5 glass elements are self-extinguishing according to the UL 94 V0 standard. The GPO3 and FR5 material are also non-marking and halogen-free. The GPO3 material is a layered insulation based on glass mat and filled polyester resin and is used for machined and sheared pieces. It has good mechanical properties and is suitable for blanking up to 6mm thick. It has good dielectric properties. The FR4, G11 and FR5 laminates are layered with a glass fabric and epoxy resin base. They have different thermal classes. LG11 material exists in two versions: - Insulation class F (155 ° C), code LG11 - Insulation class H (180 ° C), code LG11H

Request for a quote

OCV ITALIA

Italy

158B Roving is specifically designed for use in filament winding applications using epoxy resin, where high strength is required. 158B is suitable to reinforce phenolic resins. Fast wetout properties and high burst strength maximize customers’ processing and minimize costs.EXCELLENT PROCESSING Smooth runout combined with low fuzz properties, result in smoother parts and less downtime for cleanup, enabling higher efficiencies and lower manufacturing costs. FAST WETOUT Allows the processor to optimize part production speed resulting in increased productivity and reduced costs. HIGH BURST STRENGTH Excellent glass/resin bonding, which provides high burst strength in pipe or vessels. CORROSION RESISTANT Excellent corrosion resistance with Advantex® Glass compared to standard Eglass providing longer service life in applications facing corrosion.

Request for a quote

BOSSONG SPA

Italy

Highadhesion epoxy resin for heavyduty fastenings for use in different base materials as concrete, solid masonry and wood. This Bossong resin can be used also with wet concrete and flooded hole including underwater fixing (reduction of the recommended loads of 20%). Suitable for electrically insulated fastening. It has longterm resistance to hydrolysis. Excellent for applications with reinforced bars. Thixotropic consistency. The resin, due to its strong adhesion value and the ease with which it penetrates holes and hollow areas, permits secure fixing without expansion and so without stresses in the base material. It does not need premixing, the resin and hardener are only mixed during extrusion in the special mixer. It can also be used for repair and refilling. SERVICE TEMPERATURE RANGE Between 40°C /+ 40°C with T°max long period of 24°C and 40°C/+80°C with T°max long period of 50°C (ambient temperature after installation).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OCV ITALIA

Italy

PulStrand® 4100 is specifically designed for fast wetout, good processing, high glass loading and excellent laminate properties, to maximize customers’ processing and minimize their processing costs in pultrusion applications. OUTSTANDING MECHANICAL PROPERTIES Excellent shear and flexural properties in major resin systems, provide maximum part strength and long part service life. REDUCED COST Fast, uniform strand wetout leads to higher glass loading, reducing resin demand; fast wetout also increases production speed and productivity resulting in reduced manufacturing cost. MULTIRESIN COMPATIBILITY Excellent glass/resin bonding in polyester, vinyl ester, polyurethane, acrylic, and epoxy resins, providing the processor maximum flexibility with one input glass. This reduces cost with less inventory to carry and eliminates the need for costly downtime and labor to change input glass during job changes. Suitable for LFTP PA compounding applications

Request for a quote

OCV ITALIA

Italy

PipeStrand® S1000, made for fabricators that want to reduce material cost, while increasing product performance. Designed to provide excellent hydrostatic bases, fight corrosion, increase efficiency and service life in the lowpressure filamentwound pipe, tank and vessel markets OUTSTANDING MECHANICAL PROPERTIES Excellent shear and hydrostatic properties in all major resin systems, provide maximum part strength, long service life and hydrostatic design basis. REDUCE COST Fast, uniform strand wetout in all major resin systems, results in optimized part production speed and increased productivity, reducing manufacturing costs. MULTIRESIN COMPATIBILITY Excellent glass/resin bonding in polyester, vinyl ester, polyurethane, acrylic, and epoxy resins, providing the processor maximum flexibility with one input glass. This reduces inventory and eliminates the need for costly downtime and labor during product change overs.

Request for a quote

OCV ITALIA

Italy

UNIFILO® 800 Series continuous filament mats represent a large choice of tailored reinforcement solutions for efficient manufacture of various composite parts by closed mold process. EFFICIENT PROCESSING U850 high permeability product family enables enhanced resin flow in highly filled systems. U810 product family offers a good compromise between low, medium and high drapability and permeability. CORROSION RESISTANCE Excellent corrosion resistance with Advantex® Glass compared to standard Eglass providing longer service life in applications facing corrosion. U800 products are available with varying strand design and binder contents to match up with specific customer applications. U800 Series mats are compatible with unsaturated polyester, vinyl ester, acrylic and epoxy resins. They are designed to be processed in closed mold processes including RTM (high and lowpressure injection), infusion and compression molding. Applications include heavy truck, automotive and industrial parts.

Request for a quote

F/ART

Italy

Transformers for cold cathode (neon lamps), designed and produced by F/ART in Italy Input: 120-240 V, 50/60 Hz Output: 990 V - 15,000 V Current Intensity: 18 - 200 mA -Exclusive epoxy resin is used to encapsulate and protect the product, making it durable. -Compliance with European standards and CE marking -Can be used for neon tube installations with an operating voltage between 1,000 V and 10,000 V, in compliance with European standards -Possibility to adjust the light using a dimmer: external switch for traditional transformers and built-in for electronic transformers -Casing for internal protection

Request for a quote

POLITUBES

Italy

Politubes, in conjunction with DuPont, has developed a special spiral-wound tube made of heat-shrinkable polyester (Mylar HS), which enables automated fixing of permanent magnets, thereby reducing the cost of assembling these motors.Important advantages are: 1.Unlike very expensive steel rings, the spiral-wound tube also wraps around and protects the ends of the magnets, which are also subject to corrosion. 2.The trimming that often has to be done during the assembly process when using rigid rings is avoided; the Politubes spiral-wound tube adheres perfectly to the magnets, taking their shape and protecting them from cracking and scratching; this also guarantees perfect balancing of the rotor. 3.Part of the assembly process is removed, since potentially costly and often manual bandage with tape impregnated with epoxy resins can be eliminated; this avoids as well lenghty resin activation time in oven; productivity is thereby increased and hidden production costs reduced.

Request for a quote

UCIESSE S.A.S.

Italy

FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing). With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength. We carry out bushings, flanges, plates, manifolds, bolts, etc. Key Properties FR Grades are Fire Retardant High Dielectric Strength High Mechanical Strength Low CLTE Applications Arc Barriers Downhole Oil & Gas Components Electrical Housings Electrical Insulators Structural Components Terminal Boards

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

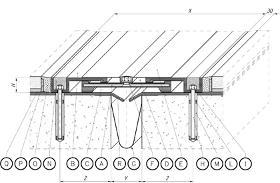

Railway expansion joint rail with water-proof and dielectric characteristics suitable to absorb longitudinal movements of the decks from 100 to 450 mm and vertical deformations up to ± 50 mm. This type of joint is designed to prevent the ballast penetration in the gap or in any active part of the joint. The RFI-approved series (built according to instruction 44/e) is for displacements from I 00 to 250 mm. Consisting of: • CNR 10018/85-compliant reinforced rubber dielectric modular pads consisting of a central bridging plate and two side elements; • mechanical anchoring system consisting of threaded bars fixed with epoxy resin; • stainless steel protection and sliding plates; • hypalon gutter; • side draining slats for under-ballast infiltration waters; • epoxy mortar transition strip between the joint and the binder. To complete the Beta railway joint the sidewalk and ballast joint is available, consisting of: • reinforced dielectric rubber flange: flat for the sidewalk and shaped fo

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

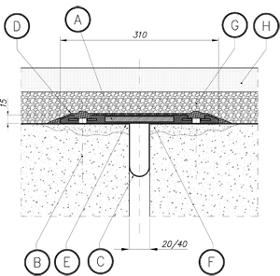

This expansion joint is suitable to absorb longitudinal and transverse displacements of the decks with span up to 25 metres and covering gaps of up to 50 mm. It consists of: • anchoring system consisting of steel anchor clamps (anchor rods) of suitable dimensions and section; • CNR 10018/85-compliant reinforced rubber elements, to be fixed to the slabs, consisting of central bridging plate and two steel bearing elements, subject to prior laying of epoxy resin bedding; • hypalon gutter, fixed to the two slab heads by epoxy plaster. POS. DESCRIPTION MATERIAL A Gap-covering plate Dielectric vulcanized rubber B M12 anchoring system C Gutter Hypalon D Pouring of modified bitumen E Epoxy plaster S Fip 180 F Restoring of base plane Fibre-reinforced cement mortar G Binder H Road surface

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

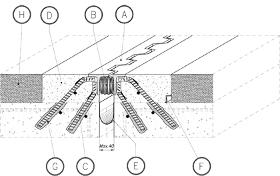

Expansion joint specifically designed for highway use within structures creating longitudinal movements of ± 15 (mm), vertical movements up to 10mm. It consists of an extruded rubber bellows, vulcanized to two 80x80x9 mm T-profiles and anchored to the slab by clamps of suitable diameter, placed at a centre distance of 240 mm. The extruded rubber, together with the steel profiles it is vulcanized to, makes up a water-tight system and seamlessly covers the entire width of the road bed. Water-tight capacity around the areas close to the joint is ensured by appropriate water-proof materials. POS. DESCRIPTION MATERIAL A 65x80x9 finger "T" profile S235JR EN 10025 B Vulcanized rubber profile CR 65 sh/a cnr 10018 C A.M. clamp Ø 16x150÷200 FeB 44K D Construction joint Fibre-reinforced cement mortar E Gutter Hypalon F "L" shaped drainage profile X5 CrNi 1810-UNI 8317 G Epoxy-resin mortar H Road surface

Request for a quote

CARONI S.P.A.

Italy

Electrophoresis and Powder Painting is performed by a fully automated new generation painting system Pre-treatment Preparation of the surface to be painted is the key to successful painting, ensuring adhesion of the layer of paint and resistance to corrosion. Parts are pre-treated non-stop in a tunnel divided into eight stages, using environmentally friendly chemicals; the plant has already been prepared for use of the new nanotechnologies. Pre-treatments: Pre-degreasing Degreasing Rinsing Rinsing Activation Phosphatizing Rinsing Demi-rinsing Electrophoresis Electrophoresis painting is a painting surface treament which gives parts made of iron, steel and other alloys (electrical conductors) improved ability to resist corrosion. It is characterized by uniform depositing of epoxy resin on the surface of the part, ensuring long-lasting good protection against aggression from chemical agents and other factors; it also ensures improved adhesion of top coats of paint. Electrophoresis painting offers several important benefits: Uniform thickness and total covering of all parts, including sharp corners. Ability to control the thickness of the paint by adjusting application voltage and time and paint temperature. Thicknesses of 15 to 40 µ may be obtained, depending on the type of paint (the newest paints can even reach thicknesses of 60 ÷ 70 µ). Excellent resistance in saline mist tests, more than 500 hours, thanks to crystalline phosphatization pre-treatment. Good appearance and therefore top quality finish: the coating of paint is distributed perfectly over the surface. Following electroplating, treated elements are rinsed with ultra-filtered water at the rising unit in the circuit, permitting near-total collection of the paint that adheres to the elements but has not been electroplated. Electrostatic Powder Painting Powder painting is a surface finishing treatment for parts made of metal (aluminum, steel etc.) and alloys characterized by electrostatic application of powder paint which is then polymerized in a kiln. Powder painting prevents corrosion and makes the objects treated resistant to chemical and atmospheric agents. It also permits creation of a vast range of different surface colors and effects: orange-peel, embossed, hammered, etc. The powder painting procedure is ecologically sound because it significantly reduces risk to workers and the environment. Powder painting, electrophoresis or sanding: our mission is achieving excellence in our work through advanced technologies and careful choice of materials. This great care and commitment allows us to pass on the savings resulting from quality and durability to our customers.

Request for a quoteResults for

Epoxy resins - Import exportNumber of results

16 ProductsCountries