- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines

Results for

Machines - Import export

IMETA SRL

Italy

Imeta is specialized in overhauling seaming machines, filling machines as well as can and cover manufacturing machines of any model. Our Exchange Program allows the clients not to interrupt production while we prepare an overhauled machine. All overhauled machines are sold with a oneyear guarantee and an integrated user manual. They meet the requirements of the CE Standard and/or other standards the Client may require. Depending on the model, the following features can be upgraded with various optional extras. The following pages show some examples of our fully overhauled machines. If you have any questions, please ask our Trade Office.

Request for a quote

IMETA SRL

Italy

Imeta provides complete changeover kits for single and multistation Cevolani machines, depending on the type of can required by the Client. The standard kit includes design and manufacturing of all necessary tools, such as rollers and knives for parting stations, rollers and formers for beading stations, complete spin flanging heads, complete necking heads and seamer changeover parts.

Request for a quote

IMETA SRL

Italy

This machine opens cans of any type, having a can height between 50mm and 270mm (other dimensions available on request). It is entirely made of stainless steel. Maintenance of the most exposed parts (blades and gears) is simple – there is no need for qualified staff. Cutting and opening of the can is carried out in a single movement using the same lever. Magnetic fittings keep the cover in place. Electric motor 220V monophase 50Hz (380V 50Hz triphase, available on request)

Request for a quote

IMETA SRL

Italy

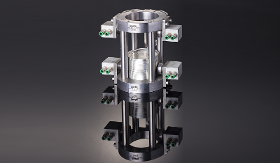

The digital dynamometer allows making simple but precise measurements of the pressure in every single lower lifters during the adjustment of the seaming machine. The dynamometer is equipped with a detailed instruction manual and a number of feeler gauges suitable for different can heights. The Dynamometer is available in both with metric or imperial scales.

Request for a quote

IMETA SRL

Italy

Thanks to the Inverter group it is possible to remove the entire mechanic clutch group, that has over 30 different part numbers (50 items). This upgrade also has the advantage of bringing significant savings during the maintenance phase, not just as regards the items that are removed, but also in terms of the gears, pins and bearings, since “softer” operations will prolong their productive lifetimes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IMETA SRL

Italy

Whereas necessary, all the cover feeders can include a pneumatic lid gapper (“No CanNo Cover”) in order to reduce the load on the feeding screws.

Request for a quote

IMETA SRL

Italy

Imeta has also developed Cover Feeders that can feed aerosol tops and bottoms and special components such as varnish rings or deepdrawn covers, as well as a wide range of special feeders with three or four screws for rectangular or oval covers.

Request for a quote

IMETA SRL

Italy

Following the great success of the AP0158.4 Cover Feeder, Imeta has also developed a simpler version of a one or threescrew cover feeder for the entire Angelus P Series. This upgrade has been particularly popular for feeding Easy Open covers, which are very difficult to feed with the original dualshaft feeder. This feeder has the same advantages of simple adjustment and performance reliability.

Request for a quote

IMETA SRL

Italy

This feeder was initially designed for installation on the Angelus 60 L and was then adapted for many other machines. The innovative feature here is that the feeding screw is inclined and parallel to the cover stack, making the feeding more natural and fluid. This feeder is adjustable and, with the substitution of just a few parts, it is suitable for any cover diameter (between 50 and 105mm).

Request for a quote

IMETA SRL

Italy

The 60L seaming machine is a multifunctional machine that meets the most diverse manufacturing needs, from cans for food or drinks, to canmaking, aerosols, composite cans and general line cans. Imeta has the necessary knowhow to transform and equip such a machine depending on different can and cover specifications, even beyond the original standard set up.

Request for a quote

IMETA SRL

Italy

Imeta provides complete changeover parts for Lanico flanging, necking and seaming machines, for any type of can a customer may be running. The standard kit includes base plates, seaming chucks and seaming rolls with coatings, in order to offer a longer productive lifetime. Partial changeover kits can be provided if, for example, straight cans need to be necked.

Request for a quote

IMETA SRL

Italy

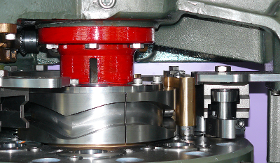

The “DESMO” Kit for Angelus 60 L includes A desmodromic cam that controls both opening and closing of roll levers at any speed A desmodromic cam that guarantees the return of the extractor shafts at any working speed A series of seaming levers allowing the adjustment of seaming rolls and very fast changeover with no need of dismantling the levers.

Request for a quote

PACTUR

Italy

The Semi-automatic Angular Packaging Machines with manual sealing arm are performing, economical, easy to use and are defined as angular because the heat-shrinking tunnel is at 90° with respect to the direction of insertion of the product. Welding arm available both with manual descent and reopening managed by a magnet, and with automatic descent, controlled by a pneumatic piston. There are three pneumatic piston controls on the machine: buttons, pedal and timer. Equipped with two Teflon mesh conveyor belts, with independent control: the first belt automatically transports the product onto the second belt, after sealing, while the second belt rotates inside the heat-shrinking tunnel. In this way, the welding and heat- shrinking operations are released and productivity is increased. As soon as a product is sealed, it moves to the second belt and the operator can immediately load the next product.

Request for a quote

PACTUR

Italy

The economic chamber packaging machines with shrink film are the ideal solution for those looking for a packaging machine that guarantees maximum reliability during the packaging phase. With an innovative and compact design, the chamber packaging machines with shrink film aim for maximum productivity without sacrificing aesthetics. A heat-shrink wrapper is the perfect choice for businesses in the food sector that want to create highly resistant packaging, capable of preserving food in the best possible way, in a package that is also beautiful to look at. In fact, heat-shrinking refines the aesthetics of the packaging, reducing the edges made up of empty film. But a heat-shrink packaging machine is also ideal for packing various objects (stationery, small parts, discs), for some types of medicines and for cosmetic products . In these cases, in addition to the benefits relating to the resistance and aesthetics of the packaging

Request for a quoteResults for

Machines - Import exportNumber of results

15 ProductsCountries

Company type