- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic loading

Results for

Automatic loading - Import export

FERPLAST SNC

Italy

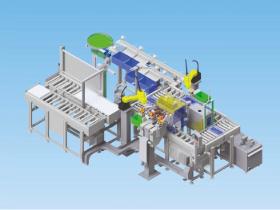

MODULAR LINE SEMIAUTOMATIC ANGULAR PACKAGING MACHINES Semi-automatic, angular machines offer maximum packaging flexibility, and a quality product at a competitive price. MODULAR 50S and MODULAR 70, which have recently been updated and revised, can be used to package products using any material, producing highly attractive results. MODULAR LINE uses an electronically controlled sealing system and the very latest safety devices. The lines can be used in automatic or semi-automatic mode, and the operating programs can be customised in order to simplify the packaging process and maximise productivity. MODULAR 50S and MODULAR 70 can also be used with the TUNNEL.

Request for a quote

FERPLAST SNC

Italy

CJS 25 HI is an electronic dosing device with load cells for semi-automatic filling of bags with max weight 25 kg. Hopper capacity 300 l, bags weight 2-25 kg. The machine is suitable for the automatic dosage of granular products with a good flowability. The dispenser is mainly formed by a welded and painted tubular steel, stainless steel, loading hopper with pneumatic closing, fast discharge channel, slow discharge channel with vibrator to achieve the exact weight, weighing hopper installed on load cells, pneumatic device for locking the empty bag, PLC operator interface and user-friendly keyboard. The dispenser can be combined with a motorized conveyor for automatic loading of the product and to a free or motorized conveyor for unloading the full bag, it can also be combinated with an automatic packaging machine. All parts in contact with the product are made of stainless steel. Ideal for packaging of pellets, granulated foods, dried pasta (short), cereals, coffee, nuts, sugar, etc.

Request for a quote

FERPLAST SNC

Italy

To be installed at the exit of the packaging machines and welding machines. ROTATING TABLE OF ACCUMULATION WITH STAINLESS STEEL STRUCTURE AND NYLON PLAN The rotary table of accumulation is generally used in the final part of the packaging lines and facilitates the discharge of the packs, facilitating the sampling operations by the operator. The rotating tables with nylon plan are available with a diameter of 800, 1200 or 1400 mm, and are suitable for bottles, cans and products that can overturn in the concave or convex turntables. The flat rotating tables can be equipped with loading systems and automatic unloading and thus be used as "accumulation areas" between an automatic machine and another. Edges and sides nylon version Flat turntable with holding sides, polyethylene plan, useful height of 810 mm and a mechanical speed variator.

Request for a quote

SCHNELL SPA

Italy

EASY HOOK lifting device allows the handling of any loads in a fully safe condition. The releasing device allows the operator to discharge the loads automatically, in a very fast and safe way.

Request for a quote

CD AUTOMATION

Italy

SCR Power Controller Unit suitable for resistive and medium or long wave infrared loads Current range – 30A, 35A, 40A, 60A, 75A, 90A, 120A, 150A, 180A, 210A, 300A, 350A, 400A, 450A, 500A, 800A Voltage Range 480V, 600V and 690V (starting from 60A) Fully isolated from the power Zero crossing firing mode (ZC) or Burst Firing (4, 8 or 16 cycles selectable) Logic input signal 4 to 30V DC typical (SSR) plus 4-20mA or 0-10V DC Linear input as an option Constant current drain, independent of supply voltage with SSR input Heater Break (HB) alarm to diagnose partial or total load failure with automatic setting, relay alarm output and front LED indication. Available as an option Side by side mounting Special design Heatsink with high dissipation value IP20 protection Complies with EMC, EAC, cULus® 508 listed and cUL® listed up to 500A as an option. UL® for 800A as an option.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CD AUTOMATION

Italy

REVO S 2PH Thyristor Power Controller is suitable for resistive and medium or long wave infrared loads Current range – 30A, 35A, 40A, 60A, 75A, 90A, 120A, 150A, 180A, 210A, 300A, 400A, 450A, 500A, 600A, 700A, 800A Voltage range 480V, 600V and 690V (starting from 60A) Fully isolated from the power Zero crossing firing mode (ZC) or Burst Firing (4, 8 or 16 cycles selectable) Logic input signal 4 to 30Vdc typical (SSR) plus 4-20mA or 0-10Vdc Linear input as an option Constant current drain, independent of supply voltage with SSR input Heater Break (HB) alarm to diagnose partial or total load failure with automatic setting, relay alarm output and front LED indication. Available as an option Side by side mounting Special design Heatsink with high dissipation value IP20 protection Complies with EMC, EAC, cULus® 508 Listed and cUL® listed up to 700A as an option. UL® listed for 800A as an option.

Request for a quote

BOSCARO SRL

Italy

Designed for the transportation and placement of concrete road barriers with an automatic load and release mechanism for quick and easy material movement. Capacity 5000 Kg Adjustment 50-800 mm Wide opening width allows usage with large kerbs and barriers. Easily adjusted by means of a locating pin and steel jaws on demand for slippery barriers

Request for a quote

BOSCARO SRL

Italy

Automatic adjustment and telescopic loading height Crane fork complete of predisposition for protection net Available also galvanized

Request for a quote

SUPREMA DRY CLEANING 100% MADE IN ITALY

Italy

Most advanced ecological & environmental friendly machine fully automatic & pneumatic operation, Loading door 500 mm for easy loading Ecological friendly – no external contamination solvent containment, filling, discharge and venting are completely sealed Adjustable Solvent Level with Computer closed circuit with heat pump compressor Freon R407a LOW NOISE – Scroll technology - Advanced super fast & efficient drying circuit Fridge gauges and pressostat group (High & low pressure) , with safety valve, soundproof compressor Advanced super fast & efficient drying circuit with automatic electronic temperature adjustment self cleaning fully automatic tank with frontal windows + S.S. insert Distillation Unit in stainless steel with internal inspection light & service hatch Ergonomic shape for faster distillation and avoid overflow – fully hermetic pressurized distillator Continuous OR fractional distillation

Request for a quote

SEIT ELETTRONICA SRL

Italy

Platinum HUB is a scalable platform you can customize according to your brazing process. You can set up the layout adding multiple stations to: flux, apply brazing paste or pre-formed brazing alloy, wash, dry and cool the parts you are processing, mark with galvo laser technology, and automatic loading and unloading the line using co-bot or industrial robots. This system will for sure adapt to your process and needs and will give you the chance to expand it and add new functions when you really need it. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fits with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the key data from your production as cycle time, temperature and more.

Request for a quote

M SERVICES SRL

Italy

Our centring-facing machines are designed to meet the request of higher flexibility, precision and simplification of small and large production end-machining , combining great power and high rigidity and also allowing to integrate an automatic loading / unloading system.The base is an electro-welded and normalized steel structure and it has been specially designed with directional slides to convey chips into the specific integrated conveyor; the underlying ribs are arranged in such a way as to be able to absorb any vibration.The use of a touch screen operator panel with easy programming ensures versatility and simplicity of application, making simultaneous machining possible on both ends.Two opposite working units are used, each moved on CN work axes (axis “Z1” and “Z2”) frontal to the piece, whereas the Self-centering clamps with oleodynamic control are moved by a third controlled CNC axis (X axis) for the management of the drilling / centering tool center as well as for millin

Request for a quote

TAMA AERNOVA SRL

Italy

Model with pallet swap Data sheet The cutting shuttle table used to support the metal sheet must be integrated into the laser and plasma cutting machine. It is equipped with a drive system that follows the laser head to focus the suction of fumes and dust in the sectors affected by the cut. Its installation ensures the quality of the production environment and the protection of those who work there. Benefits This model with automatic pallet swap is composed of two sliding pallets driven by a chain drive, a hydraulically driven external lifting unit that allows vertical pallet change from a air suction segment table with trimming collection drawers which can be extracted from the side. The laser cutting downdraft table is interfaced with automatic load/unload cells and it is composed of pre-assembled modules, easy and quick to install. Standard equipment tanks with suction segments plate support grid leveling feet position sensors

Request for a quote

FIRBIMATIC SPA - METALCLEANING DIVISION

Italy

The Masterwash Logica Blue is the ideal solution for cleaning of turned parts and precision components for aerospace, medical and military industry. Provided with front loading door, with automatic vertical opening, parts are rotated or rocked in baskets on their horizontal axis. Great accuracy in cleanliness also in presence of complex surfaces, thanks the combined action of biodegradable detergents and spraying with rotating jet ramps. Possibility of full immersion and Ultrasonics.

Request for a quoteResults for

Automatic loading - Import exportNumber of results

14 ProductsCountries

Company type

Category

- Automation - systems and equipment (3)

- Buckets and grabs, crane (1)

- Cleaning - steel and metals (1)

- Construction - Machines & Equipment (1)

- Dry-cleaning machines (1)

- Induction heating systems (1)

- Industrial cutting machine tools (1)

- Industrial tools (1)

- Laundry and dry cleaning machinery and equipment (1)

- Package sealing machinery (1)

- Turntables (1)

- Weighing and dosing equipment (1)

- Welding, soldering and brazing - equipment and supplies (1)