- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- installation of machines

Results for

Installation of machines - Import export

SPIROL

Germany

SPIROL’s Series 2000 Vibratory Feed Systems provide higher feed rates, gentler feeding, and the ability to accommodate a wider range of part configurations and materials than conventional feed systems. The advanced state-of-the-art electronic controller combines modern technology and unique features to deliver superior performance by continuously and automatically adjusting the drive system to the natural frequency of the bowl. This variable frequency technology compensates for changes in the bowl mass to ensure consistent feed rates and eliminates bowl tuning, allowing interchangeable bowls with a single drive. Additional benefits include increased energy efficiency, clockwise/ counterclockwise capability, reverse rotation, and significantly lower noise levels. The controller utilises a touch screen interface with the capacity to store 50 recipes. This system is ideal for fragile, tactile, and slippery parts. Visit www.SPIROL.com to learn more!

Request for a quote

SPIROL

Germany

The Model CLX operates the same way as SPIROL's Model CL, yet this extra-large Compression Limiter Installation Machine is custom-designed to accommodate larger assemblies outside the standard footprint of the Model CL. Visit www.SPIROL.com to learn more!

Request for a quote

SPIROL

Germany

This robust, vertical installation machine is specifically designed to install Compression Limiters into a variety of plastic components. The machine is available in two models: the CL1000 is capable of 4.4 kN (or 1,000 lbs.) of installation force and the CL2000 is capable of 8.8 kN (or 2,000 lbs. of installation force, and is available with multiple installation tips in nearly any configuration at various elevations. The incorporation of a touchscreen operator interface machines makes our machines easy to use and customisable. Language conversion is easily executed to support international use. The Model CL is equipped with installation verification to ensure that the machine has completed a full installation cycle and a Compression Limiter was installed at each location. This highly flexible platen style machine with 228mm x 279mm (9" x 11") working area. The Model CL is available with optional enhancement features for error-proofing and maximum efficiency.

Request for a quote

SPIROL

Germany

This versatile tool is ideally suited for low to moderate levels of production for assemblies that require installation forces up to 22.2 kN (5,000 lbs). The Model PMX Extra Heavy Manual Pin Inserter easily accommodates quick change-overs. The fixture is simply replaced at the base of the machine, and the pin diameter is easily changed by switching the pin driving chuck. This Extra Heavy Duty Manual Pin Inserter will provide smooth operation, repeatability and durability.

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

MACHINE OUTER CASING REVISION MACHINE MECHANICAL OVERHAUL CNC PERIODIC MAINTENANCE AND GENERAL MAINTENANCE SERVICES MACHINE TRANSPORTATION MACHINE INSTALLATION MAKING IDLE MACHINES OPERATIONAL MANUFACTURING AND APPLICATION OF MACHINE COMPONENTS

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Self-tapping insert installation tool for all types of self-tapping threaded inserts (with cutting slots Ensat 302, with cutting holes Ensat 307 and Ensat 308) and in different materials (galvanized steel, stainless steel, brass, plastic) For machine use Depth of grip adjustable with bushing Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTECKER SP. Z O. O.

Poland

We provide complete assembly, disassembly and service. Our technicians can install machines and industrial lines in your factory or at your customers' premises." Ease. We have a strong team of mechanics and electricians with experience working in different countries, under different conditions and with different machines. We communicate in English, German and Polish. We have the necessary equipment and tools to perform all tasks. We always come to the project fully equipped and ready for work. We implement the project based on the given documentation, adapting to the customer's specifications. We provide service of the highest quality. We value safety and speed.

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided as a curtain between the roll rolls.

Request for a quote

PARSMEGA MAKINA

Turkey

Garbage separator machine is used to separate foreign grain products such as garbage and straw in wheat. The garbage purifier consists of two parts. Upper sieve part: It separates the large foreign substances in the wheat and throws them out. Lower sieve part: It eliminates small foreign substances from the wheat that pass through the upper sieve part and fall on it. Both screen wires can be easily removed and installed by hand. Wheat entering the machine from the product entrance is distributed smoothly and homogeneously on the sieve thanks to the vibromotor mounted on the center of gravity of the machine. The feeding box is oscillated with the body working by vibration on rubber wedges. With an adjustable flap, it ensures that the wheat is distributed across the entire sieve surface.

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a plactic cover,used for machine accessories.

Request for a quote

BORNEMANN GMBH

Germany

Brass types for stamping paper, wood and synthetics. In the pharmaceutical industry brass types are installed in packaging machines with corresponding brass type holders and give the product the labelling. Batch labellings, manufacturer coding and process data are thereby stamped flexibly. If you request changes, the types used can be replaced.

Request for a quote

IGUS® GMBH

Germany

This little motor has impressive torque and high RPMs. Reliable operation with quick movements of low loads. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, their precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. Motors with stranded wires are the least expensive and the most common stepper motors. The connecting wires for this type exit from the housing and will be connected with a JST connector. They are usually installed in machines and equipment that have an additional housing or are used in clean environments.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Aluminum separators automatically pick up aluminum and steel cans from all waste collected from the recycling stations. 1. Recovery aluminum cans from plastic bottles. 2. High efficiency of recovery of aluminum from city waste.

Request for a quote

MICRON AMERICA

Turkey

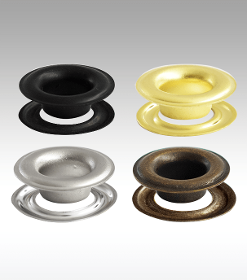

Iron Material grommets are recommended for indoor or short term outdoor use such as campaign signs that are meant to be used for a few months and get disposed. In time, when material is in contact with rain or humidity for a few months, it will cause erosion or rust. This can be installed with the same dies and machine as the self piercing brass material grommets. Iron Material Grommets Our quality Micron (Iron) Grommets are available in sizes # 1, #2, #3 and #5 for indoor/short term outdoor use grommets for an affordable short term usage fasteners for campaign signs or indoor birthday banners. The affordable pricing makes this particular grommet an option of choice.

Request for a quote

MICRON AMERICA

Turkey

Our PL 20 Machine is a portable fastener attaching machine that has one hopper to accommodate the grommets to be automatically fed through its unique channeling mechanism built to a standard size. This machine also has a side pocket slot that receives the washers for safely installing your grommets with washers. As it is built to install only one size grommets, this machine can be built to accommodate installation from 1.7 to 3 grommets. The PL 20 is a semi automatic machine. A hopper and chute system feed the eyelets to the top die of the machine. This greatly increases productivity by allowing the operator to set grommets at a higher rate.The bottom washer can also be placed on the bottom die to create a better hold. Our safety system makes the installation extremely safe for the operator. The safety feature checks for any material

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Dross Press for Aluminum Recycling for secondary aluminum producer DROSS COMPRESSION SYSTEM HUAN-TAI DROSS COMPRESSION SYSTEM the equipment and the accessories helps customers to increase the metal recovery significantly. 1. Please give the amount of dross removed from each furnace each skim. As you have more than one furnace please tell us all of them. 2. How often are the furnaces skimmed. 3. What is monthly dross generation in kilo's and what is percent of monthly generation to production of good cast product. 4. What is current method of dross recovery. 5. How much aluminum is currently recovery from the dross. 6. Please send a picture of current dross pans empty and full of dross and give us the basic pan dimensions and how much dross they typically hold. 7. Please send us a picture of your current dross in storage. Also our custom alloys and designs are manufactured to fit your furnaces and dross processing applications

Request for a quote

SPIROL

Germany

This exceptionally versatile tool for post-mould assemblies is ideally suited to all levels of production: from a single unit for prototype assembly, to multiple units on an assembly line. The SPIROL® Model CM Manual Compression Limiter Installation Machine easily accommodates quick change-overs by simply: • Replacing the fixture • Swapping insertion punch/pusher tip • Adjusting the positive stop for new install height. The use of high quality shafting and bearings results in smooth operation, precise positioning, repeatability, and durability. The Model CM Manual Compression Limiter Installation Machine installs Compression Limiters ranging in diameter from M3 to M10 metric and #4 to 3/8" unified, and has a maximum insertion force of 0.9kN (200 lbs).

Request for a quote

SPIROL

Germany

An accurate and consistent method to install virtually any Compression Limiter into plastic applications requiring up to 4.5kN (1000 lbs). Install just one Compression Limiter into one assembly, or several Limiters across multiple assemblies simultaneously for increased productivity. The Model CP’s quick-change tooling creates the flexibility to adapt the platform to a variety of products within seconds. The Model CP has a 230mm x 280mm (9”x11”) work area and is built on a rigid steel frame with high-precision shafting and linear bearings resulting in smooth operation, precise positioning, repeatability, and durability. The Model CP is available with optional enhancement features for error-proofing and maximum efficiency.

Request for a quote

SPIROL

Germany

SPIROL offers robust, vertical installation machines specifically designed to post-mould install Compression Limiters into a variety of plastic assemblies. The machines can install a single Compression Limiter or multiple Compression Limiters simultaneously into various polymers, thermoplastics and thermosets. SPIROL’s Compression Limiter Installation Machines are versatile solutions designed to be retooled to accommodate changing part configurations. All designs incorporate standardized machine components to reduce factory lead time, improve component reliability, and lower component costs. SPIROL also specializes in application-specific fixtures to ensure that all assembly components are held accurately in place through the installation process.

Request for a quote

SPIROL

Germany

Flexible, versatile solutions for post-mold Insert installation into thermoplastic and thermoset plastics. SPIROL's Installation Machines are the ideal foundation for stand-alone systems and enhanced assembly systems provided by SPIROL. Our standardized, time-tested, modular designs are robust, reliable and easily adjustable — allowing simple customisation to meet the specific needs of your application. More than 80% of the components in the Insert Installation Machines we design are pre-tested and production-proven standard items. This translates into faster delivery, greater reliability, and lowest cost for Insert Installation Equipment of comparable quality. We specialize in custom application-specific part holding devices. Fixturing – holding your components accurately and firmly during insertion – is a critical element to the performance of your assembly equipment.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Suitable for online printing of large text and graphics directly onto the sealing film. Can be combined with our online inkjet printer PM460 for simultaneous printing of fixed and variable texts and graphics.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Our entry-level model for printing fixed text and graphics on (coated) paper or Tyvek. Suitable for installation on blister packaging machines and can be combined with our PM460 online inkjet printer for printing fixed and variable content at the same time.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Online printing of variable data such as batch number, production date, etc. Suitable for installation on blister packaging machines. Can be equipped with different inkjet systems.

Request for a quote

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

MICRO-EPSILON

Germany

Capacitive sensors are designed for non-contact measurement of displacement, distance and position, as well as for thickness measurement. Due to their high signal stability and resolution, capacitive displacement sensors are applied in laboratories and industrial measurement tasks. In production control, for example, capacitive sensors measure film thickness and application of the adhesive. Installed in machines, they monitor displacement and tool positions.

Request for a quote

SPIROL

Germany

Some of SPIROL's standard Pin Installation Models can be equipped with a pusher punch (in place of a pin insertion quill) to press Threaded Inserts into plastic assemblies. The most appropriate Installation Machine depends on the actual insertion force required to press the Insert into the plastic hole and the desired productivity. Generally speaking, the Model PMH Heavy Duty Installation Machine is typically used for low to medium volume installation, and for medium to high volume installation, SPIROL's Model PH/PHX Platen-Style Installation Machines can be used for simultaneous installation of several Press-In Inserts at the same or different elevations. Due to the length to diameter ratio of Press -In Inserts, it is not possible to cost-effectively tube feed this type of Threaded Insert with SPIROL's automatic feeding and Installation machines.

Request for a quote-A3_FA_IMG_Single-01-cut-Labels_RGB-L_EN_7274199d.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Energy capacity 3,600 Nm/cycle Stroke 50 mm Strong and adjustable: Also in ACE's range of units ares heavy duty industrial shock absorbers, which can be adjusted. The models from the A1½ to 3 range, which weigh between 7.55 and 35.5 kg, are extremely robust, ready-to-install hydraulic machine elements with impressively high energy absorption levels and a wide range of damping rates. Their special aspect is the flexibility,as all the absorbers can be adjusted using a socket on the absorber base and be perfectly adapted to the required data. The A models cover a range of effective loads from 195 to 204,000 kg and can absorb up to 44,000 Nm energy.

Request for a quoteResults for

Installation of machines - Import exportNumber of results

198 ProductsCountries

Company type

Category

- Industrial maintenance (28)

- Recycling - machines and installations (25)

- Machine tools - metal machining (14)

- Screw cutting - steels and metals (9)

- Punching machine tools (7)

- Copper wires and cables (4)

- Filtering equipment and supplies (4)

- Oils, cooking - machinery and equipment (4)

- Waste treatment and recycling - machines and installations (4)

- Custom packaging (3)

- Electrical & Electronic Components (3)

- Mechanical engineering - custom work (3)

- Water refrigerants (3)

- Bending - steels and metals (2)

- Chemical industry - machinery and equipment (2)

- Computer engineering (2)

- Fastening devices - machines for production (2)

- Refuse handling - machines and systems (2)

- Sensors (2)

- Solar energy - installations (2)