- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection- plastics - machinery

Results for

Injection- plastics - machinery - Import export

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

Our plastic injection suppliers have many years of experience and are certified by the automotive, defense and medical industries.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Most of the plastic products are produced by injection method. Injection in summary; It is the process of injecting the melted raw material into the mold at a certain temperature and proportion and obtaining the plastic product after it cools. It is a method widely used in Turkey and in the world. As AYBERSAN Plastik Kalıp Sanayi, we also house the plastic injection process, which is an indispensable part of our injection mold production, within our company. Plastic injection; raw material amount, machine temperature, runner temperature, cooling time etc. It is a process that includes many factors at the same time. If it is not done by experts, there may be burrs, depressions, bursts, etc. in the product. undesirable consequences are inevitable. Our company, which sees quality and satisfaction as equivalent, has made and continues to make all necessary investments in this regard.

Request for a quote

ACKOR MOULD LIMITED

China

Your relaible partner from China for injection molds & moulding parts with high- quality and cost-effective solutions. ISO 9001:2015 & IATF 16949 accredited

Request for a quote

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date pet preform injection molding machine design. Such as the construction of clamp pistons tighten centrally and working even without lubrication. Our pet preform molding machines have wide column intervals and we provide them with euromap standards on our pet preform injection machines. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our pet preform injection machine. Same point precision stop is possible with our pet preform molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for pet preform injection mould changing.

Request for a quote

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date injection molding machine design. For example the construction of clamp pistons tighten centrally and working even without lubrication. Our plastic molding machines have wide column intervals and we provide them with euromap standards. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our plastic injection machine. Same point precision stop is possible with our molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for injection mould changing. Our customer can have almost zero defects, scrap and failures with our plastic molding machines. Wit the help of our user friendly software, operator work pretty easy during plastic injection process.

Request for a quote

POFI-ENGINEERING

Luxembourg

Dispergator for sandwich panel production lines Mixing concept Because of changes in regulations on additives and the complexity of for-mulations, items in the Polyol blend viscosities were varied and are very difficult miscible or even immiscible. The result is a foam very difficult to implement, surfaces in contact with the plate full of bubbles, adhesion problems, shrinkage problems, bubbles, … To circumvent the lack of miscibility of the components we have developed two elements allowing a dispersion of additives and the gas into very small particles homogenously distributed in the Polyol. Therefore, when the Polyol is mixed in the mixing-head with Isocyanate, additives are much more reactive and there is no concentration of gas or random foaming agents that create bubbles surface states or « potato fields. ». The disperser is to this day an essential element of the production units of polyurethane foams and have a great effect on PIR. It is available as low pressure (air...

Request for a quote

MATRIZ JUBILANTE UNIPESSOAL, LDA

Portugal

Plastic injection and mold production with high standards. Make your request.

Request for a quote

EBL POLYESTER

France

PLASTALAK is a protective device for scaffolding posts,Designed to improve pedestrian safety

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

We make 50-60 injection molds up to 1500 kg every year. Our own design office take care of the whole tool implementation and its complete documentation. We manufacture single and multi-component tools depending on our customers requirements. We have experience in the construction of gas molds as well. Feel free to learn more about us visiting our website - www.plastema.pl

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

Our injection department is also involved in injection molds testing. We test injection molds for tool shops and customers who import molds, e.g. from China. In addition to tool testing, we also assess the quality of workmanship, check the compliance of the construction documentation with the actual state and possible modifications to the forms.

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

We design and manufacture injection molds. Our design department manufactures about 50-60 injection molds every year - only for its own needs. We design cold-runner, hot-runner, one-component and multi-component tools.

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic caps for parfume/cologne bottles

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic injected parts for different markets

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic caps for different markets

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic injected hookah parts

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Injected Plastic Caps for cosmetic industry

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic Injected Automotive Parts

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

NOVELTY STEEL

Turkey

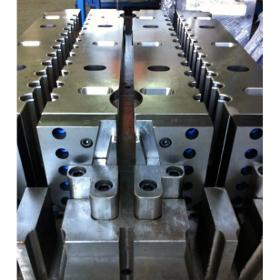

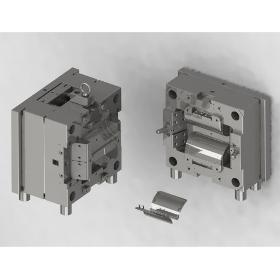

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RAMIREX - PLASTICOS DE AGUEDA, LDA.

Portugal

Ramirex - Plásticos de Águeda, Lda. is a Portuguese company with 40 years' experience in the field of plastic injection moulding, manufacturing in its own moulds - catalogue items, or in customer moulds - exclusive pieces. We produce a wide range of catalogue items, from furniture accessories (e.g. sofa legs, made-to-measure roller shutter doors, bats and tops), to drawing and office equipment (e.g. squares, rulers, protractors, paper trays, pen cups and magazine holders), and fencing material (e.g. fasteners and tops). We also manufacture specific and exclusive technical parts for various areas (e.g. for refrigeration equipment, switchboards and various telecommunications devices), designed and developed in-house or externally according to the needs of each client. We are at your entire disposal to develop solutions adapted to your needs.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in custom plastic injection parts by plastic injection molding more than 15 years, our factory is from Ningbo China, we can custom all kinds of plastic injection parts,steel pins inserted plastic parts. We have a variety of injection molding machines, large injection molding machines and small injection molding machines, vertical injection molding machines and horizontal injection molding machines, according to the type and structure of plastic components to choose the most suitable machine to produce, thus saving production and improving production efficiency and quality assurance. Plastic injection parts is very simple & popular in all industries, such as plastic cover, plastic knob,plastic bracket,plastic flange,plastic valves,plastic gears,plastic bushing,plastic base,plastic shafts,plastic mountings, plastic coupling,plastic fabrications,etc. welcome contact us for a quoting!

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in custom plastic molded parts by plastic injection molding more than 15 years, our factory is from Ningbo China, we can custom all kinds of plastic molded parts,steel pins inserted plastic parts. We have a variety of injection molding machines, large injection molding machines and small injection molding machines, vertical injection molding machines and horizontal injection molding machines, according to the type and structure of plastic components to choose the most suitable machine to produce, thus saving production and improving production efficiency and quality assurance. Plastic parts is very simple & popular in all industries, such as plastic cover, plastic knob,plastic bracket,plastic flange,plastic valves,plastic gears,plastic bushing,plastic base,plastic shafts,plastic mountings, plastic coupling,plastic fabrications,etc. Plastic injection molding is suit to complicated plastic parts with complex profile or structure, welcome contact us for quoting!

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in custom plastic molded parts by plastic injection molding more than 15 years, our factory is from Ningbo China, we can custom all kinds of plastic molded parts,steel pins inserted plastic parts. We have a variety of injection molding machines, large injection molding machines and small injection molding machines, vertical injection molding machines and horizontal injection molding machines, according to the type and structure of plastic components to choose the most suitable machine to produce, thus saving production and improving production efficiency and quality assurance. Plastic parts is very simple & popular in all industries, such as plastic cover, plastic knob,plastic bracket,plastic flange,plastic valves,plastic gears,plastic bushing,plastic base,plastic shafts,plastic mountings, plastic coupling,plastic fabrications,etc. Plastic injection molding is suit to complicated plastic parts with complex profile or structure, welcome contact us for quoting!

Request for a quoteResults for

Injection- plastics - machinery - Import exportNumber of results

45 ProductsCountries