- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection resins

Results for

Injection resins - Import export

PEEKCHINA CO., LTD.

China

Form: Granule; Compositon: 100% PEEK Resion; Feature: Standard Viscosity; Application: Film Manufacturing & Injection Moulding.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA HT RESIN is a resin-based on isocyanate and epoxy (EP), which reacts after adding a catalyst. ALWA HT RESIN offers a range of possibilities for producers of fibre-reinforced materials (e.g., glass fibre, kevlar and carbon), semi-finished and finished goods. The system is also suitable for prepreg and reaction compounds. ALWA HT RESIN is particularly interesting for the aerospace and aircraft industry as well for the rail transport, automotive and electronics industry. The application area of epic resins are electro casting resins, lamination and injection technology (RTM procedure), vacuum infusion, casting and ramming compounds, impregnation resin, casting and injection moulding process as well as prepreg technologies, among others. ALWA HT RESIN is offered in two versions. *ALWA HT RESIN M100 with approx. 50 mPa s *ALWA HT RESIN M2200 with approx. 2200 mPa s The resins can be mixed with one another which enables a flexible adjustment of the viscosity.

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

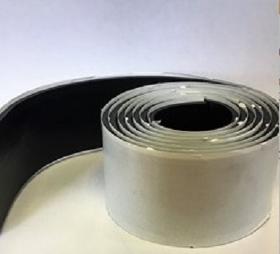

APPLICATIONS For the reconstitution of insulation for low voltage joints. For permanent waterproofing of low and medium voltage taped joints. For preventing leaks of resin during injection in low and medium voltage taped joints. PRODUCT BENEFITS Interleaving overlaps the edges of the coil, allowing easy separation from the tape. Service temperature ‐30 to +80°C. Particularly suitable for hot climates. Good compatibility with all resins used to protect joints. Resistant to water and ozone. Good physical properties, which show a high degree of stability under conditions of use.

Request for a quote

ALPHATEC ENGINEERING S L

Spain

ALPHATEC 342 is an injection resin which is used with our high-pressure injection system to repair all types of machinery foundations, where cold joints or stress cracking has been found. The repaired foundation will often exceed the strength of the original.

Request for a quote

RÜHL FEUERLÖSCHMITTEL GMBH

Germany

Polyester resins (UP resins) form the basis of our product range in the glass fibre reinforced plastic systems business area – with a wide variety of applications. They range from thixotrope standard systems for manual lamination and fibre spraying to low-viscosity standard formulations for polymer concrete and sanitary applications to numerous special formulations for specific requirements. With a broad spectrum of properties and applications, our UP resin systems are suitable for products in a wide variety of industries. Typical properties Dense matrix / composite of approximately 1.1 g/cm³ / 1.5–1.7 g/cm³ Fibre content 25-50 % of total weight Moulded part mass per unit area of 4500-8000 g/m² Flexural modulus of elasticity 5000–25,000 MPa (with reinforcing mesh) Bending resistance of 130–260 MPa (with reinforcing mesh) Impact resistance of 45–95 KJ/m² Reinforcing materials: Continuous or cut glass fibre mats, fleece Mesh Non-crimp fabrics Special formulations and versions Styrene-reduced, environmentally friendly formulations Low-viscosity injection resins with reduced exothermic peak Formulations for the pultrusion process Systems with high chemical and hydrolysis resistance DIN 1140 versions with special mechanical values and dimensional stability under heat greater than 100 °C (HDT > 100 °C) Resins with good adhesion for combination with PVC Resin systems with shipping industry approval: Det Norske Veritas/Lloyd’s Register of Shipping/Germanic Lloyd Coordination with gel coat/top coat for surface refinement Flame protection formulations Electrical industry: UL 94 V0 Rail vehicle construction: DIN 5510 (S4, SR2, ST2)

Request for a quote

PURIN POLYURETHANE

Turkey

Injection foams are liquid resins that can be injected into all gaps from capillary cracks to large cracks in concrete structures. It can be used in areas such as crack repair and building consolidation, especially in waterproofing, by converting from polyurethane liquid to solid by creating chemical reaction in seconds after injection process. Injection foams offer the possibility to apply in different forms for different purposes, from hard to very soft.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Injection resins - Import exportNumber of results

6 ProductsCountries

Company type