- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection moulding technology

Results for

Injection moulding technology - Import export

KUNSTSTOFFTECHNIK SCHMID GMBH & CO. KG

Germany

Customers from a wide range of industries rely on technically sophisticated injection-moulded parts made with up to three components. Our unique strength lies in the areas of multi-component technology, thermoplastics processing, elastomers and high-performance plastics.

Request for a quote

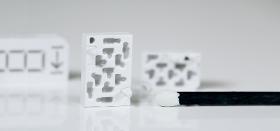

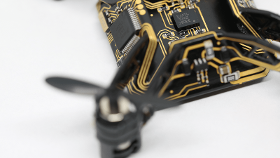

TEPROSA GMBH

Germany

3D-MID are three-dimensional, spatial circuit carriers. The abbreviation MID stands for Molded Interconnect Device, or also for Mechatronic Integrated Devices. The term extension Mechatronic Integrated Devices as opposed to Molded Interconnect Devices (origin Molded = injection molded) is increasingly being used, since the three-dimensional basic bodies are no longer manufactured exclusively through the use of injection molding technology and no longer exclusively from plastic.

Request for a quote

HODA, UAB

Lithuania

2K or 'two-shot' injection moulding consists of processing two different polymers (or two different colours of one polymer) into an end product by means of one injection moulding process. This technology enables several functions to be integrated into an injection moulded product. One of the major advantages of 2K injection moulding compared to overmoulding is that the polymer to be injected is still hot and has not shrunk yet. This virtually excludes the risk of burrs being formed on the second component. Another significant advantage is the cycle time gained, the constant process and the fact that manual insertion is not required, thus avoiding the risk of damaging the first component.

Request for a quote

PHILPLAST LTD.

Bulgaria

Philplast can produce a wide variety of plastic items using the technologies of injection moulding with the following characteristics: Weight: from 0,5 to 1000gr.; Clamping force of the machines: from 50 to 200 tons; Materials: ABS, PA, PC, PS, POM, TPV, TPE, PP, PE, as well as reinforced plastics (glass or mineral filled); Industries: home appliances, automotive, electronics, cosmetics, detergents and others. We also offer a complete set of services that help in the manufacturing of plastic products and mould maintenance: Design, 3D model and a “Rapid Prototype”; Tooling; Mold servicing and repairs; Additional processing and assembly of plastic articles;

Request for a quote

FATRA A.S.

Czech Rep.

Plastic crate Plastic crate produced with injection moulding technology – primarily intended for use: In households. In food industry – for pastries, fruits and vegetables. Processed materials PP HDPE PP (polypropylene) is the second most frequently used material in Europe. Its share in consumption of plastic materials ranges about 20 %. Polypropylene is By its features and use, polypropylene is similar to polyethylene, therefore both of these polymers are classified in the same group indicated as polyolefins. Unlike PE, PP however features higher strength and consistency, and since its melting temperature is higher, it shows good temperature stability. PP consistency imparts good dimensional stability to products. Polypropylene can be found almost anywhere: in packaging materials, household appliances, clothing, means of transport, and many other products. More than half of the world PP production is used for packages. It is also used in technical applications. It is used...

Request for a quote

FATRA A.S.

Czech Rep.

NOVODUR – non-plasticized PVC The title NOVODUR ® indicates non-plasticized PVC granulates. It is a mixture of various additives combined suitably according to its further use. The most important additives to non-plasticized mixtures may in addition to PVC include thermal stabilisers, lubricants, separation agents, filling agents, pigments, flame retardants, light stabilisers, antioxidants, various modifiers, etc. Novodur granulates are processed subsequently using mainly extrusion and injection moulding technologies. Processed materials PVC-U PVC (polyvinylchloride) is a universal, proven, and reliable material. It was developed in the thirties of the 20th century as one of the first synthetic materials – plastics. It is a material well workable using various technologies, e.g. rolling, extrusion, depositing, or casting, therefore it is predestined for wide range of applications. PVC has a unique combination of features, which can be further modified in various ways using...

Request for a quote

FATRA A.S.

Czech Rep.

Floor tiles Multifunctional plastic tiles with TERRASOL click-system, used in both, the exterior and interior, manufactured using the injection moulding technology Floor tiles were developed in collaboration with the Swiss company Siltex. Product advantages Click System – easy to install, easy to manipulation. Lining with fillets possibility. Easy-care. Coloured variants. UV-stabilized. Temperature resistant, no deformation under heat/cold exposure. Water drainage. Resistent to most chemicals. Processed materials PP PP (polypropylene) is the second most frequently used material in Europe. Its share in consumption of plastic materials ranges about 20 %. Polypropylene is By its features and use, polypropylene is similar to polyethylene, therefore both of these polymers are classified in the same group indicated as polyolefins. Unlike PE, PP however features higher strength and consistency, and since its melting temperature is higher, it shows good temperature stability. PP...

Request for a quote

FATRA A.S.

Czech Rep.

NOVOPLAST – plasticized PVC The title NOVOPLAST ® indicates plasticized PVC granulates. It is a mixture of various additives combined suitably according to its further use. The most important additives to plasticized mixtures may in addition to PVC and plasticizers include thermal stabilisers, lubricants, separation agents, filling agents, pigments, flame retardants, light stabilisers, antioxidants, various modifiers, etc. The content of plasticizer in the mixture is determined by final hardness of the mixture. Hardness of resulting mixtures ranges from 45 degrees on the Shore A scale to the hardest Novoplast – 60 degrees on the Shore D scale. Novoplast granulates are processed subsequently using mainly extrusion, injection moulding, and mould pressing technologies. Final products manufactured from plasticized NOVOPLAST® granulates are various types of hoses, hoses with special resistance against gasoline, diesel, oil, frost, etc., technical mouldings, floor covers, outsoles,...

Request for a quote

PHILPLAST LTD.

Bulgaria

Philplast can produce a wide variety of plastic items using the technologies of injection molding: - Technical articles - Caps - Various plastic elements Our products have numerous applications in multiple areas of production such as: home appliances, automotive, electronics, cosmetics, detergents, etc. In the creation of injection-molded articles we use a wide variety of plastic materials: ABS, PA, PC, PS, POM, TPV, TPE, PP, PE, as well as reinforced plastics (glass or mineral filled) . All materials are sourced from established and reliable suppliers from Germany, Italy, Bulgaria and Great Britain. The size of our injection-molded articles can weigh up to 1000gr with a clamping force of the machine from 50 to 200 tons.

Request for a quote

LARKIS SP. Z O.O.

Poland

Molded rubber products are used in a variety of responsible environments such as oils, acids and alkalis, and are used in many fields of automotive, household appliances, medicine, orthopedics and in packaging industry, Production molded to any shape: gaskets rings washers shock absorbers tiles rubber-metal parts stopper corks and other articles according to agreements with the customer. Molded rubber parts are produced by press molding and by injection molding, using the latest technologies. Manufactured of: silicone rubber, LSR, EPDM, NR, SBR, CR, FKM, etc. with hardness of 5-85 Shore A

Request for a quote

MARXAM PROJECT

Poland

Die-cutting electrical discharge machining (EDM) and wire electrical discharge machining (WEDM) allow for the machining of precise, difficult-to-machine elements with complex shapes, for which the access of a conventional cutting tool is difficult. The wire EDM machining process is also used in our plant to regenerate tools and create injection moulds, dies and gears. Various technological methods are used for the processing of metal products. Wire EDM machining is an erosion treatment that, through electrical discharges, allows metals to be given various shapes, often impossible to achieve by traditional machining methods. Die sinking and wire erosion EDM are the services that Marxam Project encourages you to cooperate in the field of material removal treatment. We are the precision machining company with a wide variety of services, if you are looking for metalworking services, do not hesitate to contact us.

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

Many years of our technologists' experience in the field of projects implementation and development of technologies allow us to help with our customers' obstacles. We can deal with: - technology development in injection molding plants, - we help in the preparation of a business plan and commissioning of entire production plants or injection department in plants that have previously outsourced production to an external injection molding company.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Since the 1980’s, we have been a leading producer of superfine powders for Metal Injection Molding (MIM). Our expertise and advanced atomization technology enable us to produce very fine MIM powders down to 10µm. Products and Sizes Our MIM water atomization technology is compatible with most conventional high-performance stainless steels and alloys. Special size distributions are available as well as some standard sizes. Grades: 17-4PH®, 70/30 Fe/Cr, 430L, 316L, other 300 Stainless Steel series Sizes: Typically smaller than 20µm Austenitic Stainless Steels 316L used in MIM applications which require good corrosion resistance, strength and ductility. Also available 304L and 310L. Ferritic Stainless Steels 430L ferritic stainless steel combines good magnetic response and some corrosion resistance. Also available 409L, 410L, and 434L.

Request for a quote

HELAPET LIMITED

United Kingdom

Helapet offers unrivalled quality in the design and manufacture of our inline disc filters, both as off-the-shelf products or custom made specials. We supply filters for OEM and end-user applications in a wide range of markets including pharmaceutical, environmental monitoring, print, food and drink and electronics. Helapet strives to introduce added value to our filtration products, using consultancy based manufacturing and comprehensive testing to meet customer expectations. Our Vari-Disk® Service allows clients to select from a wide range of filter media, inlet/outlet connectors and housing sizes to best suit individual filtration requirements. Compliant to ISO 13485:2013, our membrane disc filters are in-house manufactured using the latest injection moulding and ultrasonic welding technology to deliver a top-quality product. All Helapet filters are tested before despatch and supplied with full lot traceability and certification.

Request for a quote

MARSI GROUP D.O.O.

Slovenia

MASS PRODUCTION OF PLASTIC PARTS Our equipment enables us to develop and produce high quality plastic parts. We have many years of experience with mass production of plastic parts – we produce batches up to 100 Mio pcs per year. Fully automated manufacturing process enables us to produce high quality products, without complaints. IML INJECTION MOLDING IML (In Mold Labeling) is an injection molding technology that automatically inserts labels (special foils) into the injection molding tool. The IML injection molding method is extremely effective when the customer wants to create a high aesthetic appearance/appeal of the product at optimal cost. 2K INJECTION MOLDING 2K injection molding is two-components injection molding performed by rotary tool. The future of injection molding of composite plastic products lies in two-components injection molding. We offer injection molding on Krauss Maffei 2K machine with clamping force of 200t, 3x 120 rotary table and SEPRO robot.

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

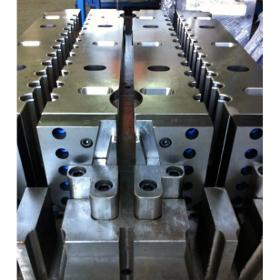

NOVELTY STEEL

Turkey

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

ACKOR MOULD LIMITED

China

Your relaible partner from China for injection molds & moulding parts with high- quality and cost-effective solutions, ISO 9001:2015 & IATF 16949 accredited

Request for a quote

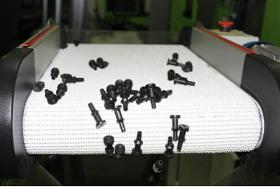

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in custom plastic molded parts by plastic injection molding more than 15 years, our factory is from Ningbo China, we can custom all kinds of plastic molded parts,steel pins inserted plastic parts. We have a variety of injection molding machines, large injection molding machines and small injection molding machines, vertical injection molding machines and horizontal injection molding machines, according to the type and structure of plastic components to choose the most suitable machine to produce, thus saving production and improving production efficiency and quality assurance. Plastic parts is very simple & popular in all industries, such as plastic cover, plastic knob,plastic bracket,plastic flange,plastic valves,plastic gears,plastic bushing,plastic base,plastic shafts,plastic mountings, plastic coupling,plastic fabrications,etc. Plastic injection molding is suit to complicated plastic parts with complex profile or structure, welcome contact us for quoting!

Request for a quote

HODA, UAB

Lithuania

HODA, UAB privately owned Lithuanian capital company, one of the biggest plastic injection moulders in Baltic states with 3400 m² area of production plant and 3500 m² of warehousing facilities. At the moment company operates 53 injection moulding machines, which gives us flexibility to produce different size and purpose plastic parts from a fraction of gram up to six kilograms of mass.

Request for a quote

HODA, UAB

Lithuania

At the moment HODA, UAB operates 54 injection moulding machines, which gives us flexibility to produce different size and purpose plastic parts.

Request for a quote

FATRA A.S.

Czech Rep.

Injection, injected products (from PP, LDPE, HDPE, etc. materials) – we offer the production on injection moulding machines with the clamp force of 420 – 800 t, moulded piece weight 80 – 3000 g. Our production assortment of injection-moulded products includes e.g. boxes, lids, tiles, protective plastic sides, or plastic containers. We offer the option of injection mould production including product development. Using your own moulds, any products according to specified parameters can be manufactured.

Request for a quote

MATRIZ JUBILANTE UNIPESSOAL, LDA

Portugal

Moulds - bottles for packaging industry, detergents, pharmaceutical

Request for a quote

MATRIZ JUBILANTE UNIPESSOAL, LDA

Portugal

Molding service provides high accuracy and consistency - injection moulding manufacturer/ supplier.

Request for a quoteResults for

Injection moulding technology - Import exportNumber of results

35 ProductsCountries

Category

- Injection moulding of rubber and plastic (6)

- Plastics moulding (4)

- Injection, plastics - machinery (3)

- Plastic products for engineering (3)

- Testing equipment (3)

- Packing and packaging - machinery and equipment (2)

- Boring - steels and metals (1)

- Filtering equipment and supplies (1)

- Laser - cutting and welding machines (1)

- Metal powders (1)