- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection molding machine

Results for

Injection molding machine - Import export

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date injection molding machine design. For example the construction of clamp pistons tighten centrally and working even without lubrication. Our plastic molding machines have wide column intervals and we provide them with euromap standards. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our plastic injection machine. Same point precision stop is possible with our molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for injection mould changing. Our customer can have almost zero defects, scrap and failures with our plastic molding machines. Wit the help of our user friendly software, operator work pretty easy during plastic injection process.

Request for a quote

REP INTERNATIONAL

France

The Microject is a micromachine of a clamping force of 60 tons designed for the injection molding and overmolding of inserts used in small parts. Usability and flexibility. Plug and Produce! Characteristics MICROJECT LSR Maximum injection volume 3.77 (at 2000 bar) or 6.94 (at 1500 bar) or 10.37 (at 1000 bar). Clamping force 60 kN. Mould dimensions 150 x 100 mm. Overall dimensions 1.2 x 0.75 m. Simplicity and flexibility Installation in 30 minutes. Mould setting time optimally reduced. Intuitive touch screen interface.

Request for a quote

REP INTERNATIONAL

France

Lean range G10 Core The G10 is the 10th generation of REP injection molding machines. With its ergonomic design and intelligent onboard solutions, the G10 generation is branded "Infinitely Smart". The G10 is available in two versions, G10 Core (Lean range) and G10 Extended (Performance range), designed to better meet the varied needs of customers. Lean range G10 Core Vertical rubber injection molding machines REP ideal for less demanding processes. The G10 Core range exists with three clamping forces 1,600 kN 3,050 kN 5,100 kN.

Request for a quote

REP INTERNATIONAL

France

Performance range G10 Extended Intelligent, elegant and efficient The G10 is the 10th generation of REP injection molding machines. With its ergonomic design and intelligent onboard solutions, the G10 generation is branded "Infinitely Smart". The G10 is available in two versions, G10 Core (Lean range) and G10 Extended (Performance range), designed to better meet the varied needs of customers. The G10 Extended is a line of presses adapted to the most demanding processes. The G10 Extended is progressively replacing the G9 generation machines and ranges from 1,600 kN (V410) to 10,200 kN (V910).

Request for a quote

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date pet preform injection molding machine design. Such as the construction of clamp pistons tighten centrally and working even without lubrication. Our pet preform molding machines have wide column intervals and we provide them with euromap standards on our pet preform injection machines. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our pet preform injection machine. Same point precision stop is possible with our pet preform molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for pet preform injection mould changing.

Request for a quote

REP INTERNATIONAL

France

In short, large flat gasket REP machines mean Clamping quality Thick traverses, multiple synchronized clamping operations; Injection of long thin sections Injection pressure up to 3,000 bar and circuit division with several injection units; Productivity Very fast 3step clamping, doubleplate kits; Ergonomics/access to the mold Widthwise heating plates, demolding kit or sliding platen. These types of machines have been developed for largeseries injection molding involving parts with inserts, for example the injection molding of battery pack seals. Based on its longstanding experience in this field, REP offers a comprehensive range of machines with largesized heating plates and adjustable configurations to fully comply with the technical specifications of each application and all client’s needs.

Request for a quote

REP INTERNATIONAL

France

Designed for the manufacture of highvoltage insulators (550 kV), this press is one of the largest presses made by REP. The dimensions of the parts to be injected explain the huge size of the press 660 mm in diameter, 2,600 mm long, moulded in one go. The production of a complete insulator is therefore performed in one or two cycles, thus significantly increasing the profitability and reliability of the parts. Machine features Closing force 24,000 kN Size of the platens 1,500 x 3,000 mm Injection volume 25,000 cm³ x 2 (2 injection units)

Request for a quote

REP INTERNATIONAL

France

The CMX (Compact Multi Station of the generation 10) This new machine replaces the former CMS generation and makes the third generation of rotary machines with 2 major innovations. Integration of the processcontrol system of the latest generation (generation 10) with all 4.0 functions. Product range with the CMX1 (160T clamping force) and the CMX2 (250T clamping force). New generation of 4station molding machines The REP solution for large productions with optimal efficiency 90% increase in productivity compared with a singlestation press. 68% increase in productivity compared with a press equipped with a double plate stripping kit. The CMX machine is available with two clamping forces 160T (CMX1) or 250T (CMX2).

Request for a quote

REP INTERNATIONAL

France

In short, large flat gasket REP machines mean Clamping quality Thick traverses, multiple synchronized clamping operations; Injection of long thin sections Injection pressure up to 3,000 bar and circuit division with several injection units; Productivity Very fast 3step clamping, doubleplate kits; Ergonomics/access to the mold Widthwise heating plates, demolding kit or sliding platen. These types of machines have been developed for largeseries injection molding involving parts with inserts, for example the injection molding of battery pack seals. Based on its longstanding experience in this field, REP offers a comprehensive range of machines with largesized heating plates and adjustable configurations to fully comply with the technical specifications of each application and all client’s needs.

Request for a quote

REP INTERNATIONAL

France

URP Joint venture United Rubber Machinery Strategic Alliance for Asian injection molding machine market between REP and LWB Steinl,

Request for a quote

REP INTERNATIONAL

France

CFrame Injection molding machine V19. Optimized floor space and maximum accessibility. The V19 is an advanced Cframe press of 400 kN available in 2 versions, plastic or rubber injection. Its accessibility from three sides makes it ideal for the injection molding of profiles and extruded hoses.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 500 kN. Size of the platens 300 x 300 mm. Injection volume 125 cm³.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 1,950 kN. Size of the platens 450 x 450 mm. Injection volume 1,000 cm³. The H49 is designed for Automated production. Injection molding (more or less simple parts). Low floor space and height requirement. An optimized cycle time. etc

Request for a quote

REP INTERNATIONAL

France

Type V410 Extended 1,600kN Machine features Clamping force 1,600 kN. Size of the platens 430 x 510 mm. Injection volume 1,000 cm³. Machine which is particularly used for the production of flat gaskets as used in fuel cell applications. This machine is available in our showroom « Area 111 » in Corbas (France) to perform your test runs for the injection molding of LSR parts.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 10,200 kN. Size of the platens 1,200 x 1,200 mm. Injection volume 5,000; 8,500 or 11,000 cm³. The G10 Extended range, performance for complex processes. Designed to better meet the various customer requirements with its embedded intelligent solutions. The G10 Extended range will progressively replace the G9 machines and extends from 1,600 kN (V410) to 10,200 kN (V910).

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 2,544 kN (station A) / 2 x 785 kN (station B & C). Size of the platens 630 x 500 mm. Injection volume 1,000 cm³; 2,000 cm³ or 5,000 cm³. The CMX (CompactMultiStation Generation X G10) is a 4station injection molding press 1 injection station (A), 2 curing stations (B and C), 1 demolding station (D). The CMX machine is available with two clamping forces 1,540 kN (CMX1) or 2,544 kN (CMX2).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REP INTERNATIONAL

France

V410 LSR Machine features Clamping force 1,600 kN. Size of the platens 430 x 510 mm. Injection volume 1,000 cm³. Machine which is particularly used for the production of flat gaskets as used in fuel cell applications. This machine is available in our showroom « Area 111 » in Corbas (France) to perform your test runs for the injection molding of LSR parts.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 1,100 kN. Size of the platens 335 x 400 mm. Injection volume 400 or 1,000 cm³

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: POM, PP, PA, PE, ABS Process: Injection molding Precision machining Extrusion Application: Agricultural machinery General machinery

Request for a quote

NOVELTY STEEL

Turkey

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quote

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

CRYOSNOW GMBH

Germany

• Small required space • Integration in injection molding machines, especially for in-mold-decoration • Easy installation on robots, linear axle and brackets • Separate 24V control of compressed air and CO2 • Liquid CO2 supply with CO2 cylinder bundles including dip tube or CO2 tanks • Short response time due to additional CO2 valve on the nozzle • Automated cleaning of injection molds, metal and plastic parts

Request for a quote

AAAGILER GMBH

Germany

Typical fields of application for our vibration damping mats include: - Heavy machine tools - Injection molding machines - Hydraulic systems / hydraulic presses - Punching machines / punch presses / automatic punch presses - coining presses - Die hammers - transformers - generators - Transport carts / truck trailers - Sensitive measuring, electronic and testing equipment, e.g. precision balances and microscopes - Vibration isolation of machine foundations - Vibration and noise damping of rails installed in the track system (high-speed trains, subways, streetcars)

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 20 form, fill and seal machine enables the production of bags made of polyethylene film from a flat film roll. The film can be neutral or coloured, with continuous printing or centred printing with print mark. The design of the machine and the low loading height allow ergonomic adaptation to a manual feeding station or easy connection to a feeding unit, such as an automatic counter, an automatic weighing system, an automatic assembly machine, an injection moulding machine, a conveyor belt or similar.

Request for a quote

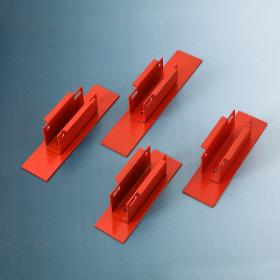

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

This metal bracket is called bucket, carrier or clamp, which is used on injection molding machine, to fix the digital display on the machinery body, many brackets or clamps are used to hold electronics or goods on the body or on the wall, the metal brackets / clamps can be "L"shape,"M"shape, "U"shape,etc, which are mainly formed by metal stamping, the material can be flexible like iron, steel, stainless steel, aluminum, spring steel.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Heating bands are the ideal solution for the heating of tubes an cylinders. Mica band heaters, frequently used as nozzle heaters, are made with a plastic-tight stainless steel casing. Such mica heating bands are in many dimension available from stock. The Ceramic heating band type is suitable specially for applications with high watt density and therefore for higher temperatures. Ceramic band heaters, also known as ceramic ring heaters or cylindrical ceramic sectional heaters, are attached to the contact surface by means of a clamping mechanism. A preferred field of use for ceramic band heaters is the heating of plasticising cylinders, bushings and nozzles of injection moulding machines and screw barrels of extrusion machines. For thermal optimization and process control ceramic band heaters can also be offered with insulation jackets or air cooling.

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

In the area of elastomer technology, the Zimmer Group uses the most modern production processes to manufacture sophisticated workpieces from elastomers. In addition to the transfer molding process, in which the elastomer is placed in a mold, pressed into shape with a die and vulcanized under pressure and heat, we also use the injection transfer molding process. Here, the starting materials are pressed into the mold on an injection molding machine and vulcanize out there. With these two processes, we process a wide range of elastomers such as NBR, silicone, EPDM, FPM or polyurethane. In terms of quantities as well as dimensions, the sky's the limit, because we can manufacture almost any quantity required, from special solutions in quantities of one to medium-sized small batches and large series of more than 10,000 units.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Injection mold production is a complex process that cannot be underestimated. The resulting product is the main element to be used in injection molding machines. Therefore, at every stage of the process, there are improvements that need to be made in line with the research and the data obtained from these researches. The R&D process, which started with the examination of the samples we received, continues at the design and injection stages. As AYBERKSAN, our aim is not to present a large number of products with the existing data, but rather to increase the data we have and to present better quality, problem-free and economical solutions. The process we call development cannot happen without research. With this awareness, we, as AYBERKSAN Kalıp Sanayi, continue our research to take the experience we have gained so far to the next level, to add a new one and to develop it.

Request for a quoteResults for

Injection molding machine - Import exportNumber of results

172 ProductsCountries

Company type

Category

- Injection moulding of rubber and plastic (16)

- Plastic products for engineering (16)

- Moulding, rubber - machinery (7)

- Metal furniture (6)

- Shoes - industrial machinery (5)

- Plastics moulding (4)

- Injection, plastics - machinery (3)

- Plastics - machines and material for industry (3)

- Gears (2)

- Plastic products for the electrical industry (2)

- Seals (2)

- Testing equipment (2)

- Anti-vibration supports (1)

- Bearings - ball, needle and roller (1)

- Bearings, ball (1)

- Blast cleaning equipment (1)

- Bottles and jars, plastic (1)

- Connectors, electronic (1)

- Construction machinery (1)

- Custom packaging (1)