- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection and extrusion

Results for

Injection and extrusion - Import export

ZS INDUSTRIES CO., LTD

China

Material: POM, PP, PA, PE, ABS Process: Injection molding Precision machining Extrusion Application: Agricultural machinery General machinery

Request for a quote

EC PLAZA

South Korea

<Product Features> Samil Chemical's white master batch produces white master batch considering the specific gravity and MI by selecting master batch and resin for various Tio2 contents. We are minimizing the defect rate of the product through this production process and promise to supply high quality white master batch. <Product Use> injection molding, Extrusion molding, Brow molding et al. <Company Information> Samil Chemical is developing color master batch and functional master batch. In addition, it is also researching and producing eco-friendly master batch. We also supply various master layouts to domestic and foreign plastic industries at high quality and reasonable prices. We also researching and developing a variety of biodegradable master batches.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Compositon: 20%, 30% or Custom Ceramic Filled PEEK; Feature: Excellent Dimension Stability; Application: Extrusion & Injection Moulding.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Feature: Electrical Insulation and Extremely High Voltage; Application: Extrusion & Injection Moulding; Customized: Yes and contact for material solution.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Feature: Heat Insulation and Low Thermal Conductivity; Application: Extrusion & Injection Moulding; Customized: Yes and contact for material solution.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Compositon: 20%, 30%, Up To 60% Glass Fiber Reinforced PEEK; Feature: Standard Viscosity; Application: Extrusion & Injection Moulding.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Compositon: 20%, 30%, Up To 50% Carbon Reinforced PEEK; Feature: Standard Viscosity; Application: Extrusion & Injection Moulding.

Request for a quote

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

CONSTAB offers you a wide range of masterbatches and compounds for polyethylene films, such as: — Bubble Film — Electronic packaging film — Injection molding and extrusion blow molding — Foamed films — Food packaging films — Greenhouse films — Film packaging for industry and food — Industrial films — Industrial packaging films Our masterbatches and compounds provide your products with the properties they should later have.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® CORUS HD ultrasonic systems have been specially designed for cleaning high-quality moulds and precision tools. In maintenance these replace the labour-intensive and often ineffective manual cleaning. The ultrasonic cleaning process can be used for all metal moulds, in particular tools for injection moulding, extrusion, rubber processing as well as aluminium and gravity die casting. A typical structure consists of three stages: 1. cleaning, 2. rinsing and 3. passivating. The usable dimensions are matched to common mould sizes. The workpieces to be washed are placed in the tank either with the aid of a washing basket or with a lifting beam. Our ErgoStation is recommended for manual rinsing, drying and post-treatment. The working area is completely enclosed, brightly illuminated and ventilated. Operation is safe and simple, as the moulded parts are loaded laterally through a sliding door and held by a lifting device during treatment.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The WIWOX® USm Ultrasonic cleaning tanks enable individual, demand-oriented surface treatment in a single or multi-stage process. The modular design allows adaptation to almost all requirements and subsequent expansion or automation is possible at any time. Aqueous cleaning at temperatures between 60° and 80° C ensures absolute degreasing and particle removal. Organic or inorganic residues such as polishing paste, paint, plastic, release agents, oil carbon or lime can be easily removed by using the right cleaner. The workpieces are cleaned within a few minutes. The cleaning result is always perfect and reproducible. The subsequent rinsing process is followed by stain-free post-cleaning or preservation. The WIWOX® ultrasonic cleaning process can be used for all steel moulds as well as brass and copper parts. Especially tools for injection moulding, extrusion, rubber processing, aluminium die casting and gravity die casting.

Request for a quote

POLYNEO GMBH

Germany

PolyNeo GmbH looks back on decades of experience in polymer trading. A high level of professionalism, both customer and supplier contacts that have developed over the years, in-depth market knowledge, strong cost awareness as well as the extensive technical know-how of our employees constitute the strengths of PolyNeo GmbH. For decades now, we have supported producers and customers all over the world by raw material sourcing, marketing and distribution as well as tailor-made logistics services. Raw material and compounds for fibers, film as well as a diversity of extrusion and injection molding applications (mineral filled, glass reinforced, impact modified, UV modified, flame-retardant both halo and non-halo, elevated temperature modified). Broad range of different types e.g. GF 10, GF 15, GF 30, GF 35, GF 40, GF 50

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent for casting, injection moulding, blow moulding and extrusion processes of plastics and elastomers Prevents sticking, for example of excess adhesive and sealant Eliminates creaking and squeaking noises when surfaces made of plastics, elastomers and metals rub on each other For easy fitting of plastic and rubber profiles, e.g. in door and window construction Lubricant for cutting edges of paper, cardboard, veneer or textile machines, etc. Advantages and benefits NSF H1 registered Highly effective due to outstanding surface wetting and formation of separating film with antistatic properties Broad range of uses for long-term lubrication, protection, care and impregnation of material surfaces made of metal, plastic and rubber Minimal consumption through formation of extremely thin films Resistant to water and weathering Long spray tube for precision application MOSH/MOAH-free

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Service Cleaning: Our customers count on our contract cleaning team for their daily cleaning needs -. With modern cleaning processes e.g. thermal with pyrolysis, aqueous with ultrasonic or mechanical with lapping blasting we can clean and improve your high quality tools. Whether extrusion or injection molding tools, extruder screws, hot runners, nozzles, filters, molds, screens, adhesive or coating devices - everything will be cleaned by us for you! Detailed advice and documented cleaning of samples ensure consistent results over a long period of time. Test us - In addition to comprehensive advice, we offer you the opportunity to carry out your own cleaning trials of workpieces up to a length of 3 m and / or 4 t in weight. Cleaning trials: Every customer can convince himself of our offer by a free sample cleaning. Whether cleaning, surface treatment or decoating - with us you as a customer can see the result even before the first order!

Request for a quote

MIKROPOR

Turkey

Water Process Chiller is designed to meet the needs of many applications that require stable working conditions with maximum quality and cleanliness of the cold process fluid. Proses Çillerleri_Ana Görsel-min Our brand-new compact, robust and reliable MCHILL Series Water Process Chiller is designed for industrial applications and manufactured with the highest quality and safety standards. MCHILL is not only extremely compact and easy to use but also ensures an accurate control of water temperature. MCHILL Series is used for Food & Beverage Industries, Wineries, Dairies, Breweries, Bottling, Storage, Plastic Industries-Injection, Extrusion, Blow Molding, thermoforming, Laser Industry-Cutting, Welding, Profiling, Optics, Medical; Chemical & Pharmaceutical Industry-Natural Gas, Jacketed Vessels, Polyurethane, Laboratories, Healthcare, Petrochemical, Temperature Control; Engineering Industry-Machine

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd. is a professional ISO9001 certificated Metal Parts & Plastic Parts manufacturer, Located in China Ningbo, Specialized in Services of Sheet Metal Fabricating, CNC Turning & Machining, Tube Bending, Cold Forging & Hot Forging, Plastic Injection Molding & Plastic Extrusion. We outsource aluminum die castings from our friend factory, then do further machining process, finish treatments. sales@mxmparts.com

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd. is a professional ISO9001 certificated Metal Parts & Plastic Parts manufacturer, Located in China Ningbo, Specialized in Services of Sheet Metal Fabricating, CNC Turning & Machining, Tube Bending, Cold Forging & Hot Forging, Plastic Injection Molding & Plastic Extrusion. We outsource aluminum die castings from our friend factory, then do further machining process, finish treatments. sales@mxmparts.com

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HODA, UAB

Lithuania

HODA, UAB offers custom plastic manufacturing service. Our company experience and commitment includes the latest technologies and innovations in plastic injection molding, extrusion, and engineering. HODA, UAB manufactures plastic parts and assemblies that reduce overall part production costs, streamline the assembly and manufacturing process, and enhance end products with the value-added finishing services.

Request for a quote

HODA, UAB

Lithuania

There are a variety of methods used to process plastic. Each method has its advantages and disadvantages and are better suited for specific applications. These methods include: injection molding, blow molding, thermoforming, transfer molding, reaction injection molding, compression molding, and extrusion.

Request for a quote

FATRA A.S.

Czech Rep.

PVC granulate is a semi-product designed for further industrial processing (extrusion / co-extrusion, injection, moulding, coating). It is made from mixtures of plasticized / non-plasticized polyvinylchloride and respective admixtures according to final use requirements.

Request for a quote

FATRA A.S.

Czech Rep.

NOVODUR – non-plasticized PVC The title NOVODUR ® indicates non-plasticized PVC granulates. It is a mixture of various additives combined suitably according to its further use. The most important additives to non-plasticized mixtures may in addition to PVC include thermal stabilisers, lubricants, separation agents, filling agents, pigments, flame retardants, light stabilisers, antioxidants, various modifiers, etc. Novodur granulates are processed subsequently using mainly extrusion and injection moulding technologies. Processed materials PVC-U PVC (polyvinylchloride) is a universal, proven, and reliable material. It was developed in the thirties of the 20th century as one of the first synthetic materials – plastics. It is a material well workable using various technologies, e.g. rolling, extrusion, depositing, or casting, therefore it is predestined for wide range of applications. PVC has a unique combination of features, which can be further modified in various ways using...

Request for a quote

FATRA A.S.

Czech Rep.

Regranulate One of the reasons for using secondary raw materials (plastic waste) is their economic advantage caused by reduced material exigency and generally lower prices of inputs – recycled products/re-granulates. Using the higher amount of recycled product in products as an alternative to primary resources usually leads to their lower final price, which contributes to better competitiveness of products on the market. We produce re-granulates for injection moulding, blow moulding, and extrusion on modern re-granulating lines. Based on customers’ requirements, we can produce re-granulates with required melt flow index, of various colours, including re-granulates with filling compound content. In the production, we process internal and external waste. Product advantages continuous quality of inputs – secondary raw materials directly from the production stable production process with continuous control optional re-granulate colouring, or adding additives directly in the...

Request for a quote

FATRA A.S.

Czech Rep.

NOVOPLAST – plasticized PVC The title NOVOPLAST ® indicates plasticized PVC granulates. It is a mixture of various additives combined suitably according to its further use. The most important additives to plasticized mixtures may in addition to PVC and plasticizers include thermal stabilisers, lubricants, separation agents, filling agents, pigments, flame retardants, light stabilisers, antioxidants, various modifiers, etc. The content of plasticizer in the mixture is determined by final hardness of the mixture. Hardness of resulting mixtures ranges from 45 degrees on the Shore A scale to the hardest Novoplast – 60 degrees on the Shore D scale. Novoplast granulates are processed subsequently using mainly extrusion, injection moulding, and mould pressing technologies. Final products manufactured from plasticized NOVOPLAST® granulates are various types of hoses, hoses with special resistance against gasoline, diesel, oil, frost, etc., technical mouldings, floor covers, outsoles,...

Request for a quote

PHILPLAST LTD.

Bulgaria

Our tooling engineers and designers have extensive experience in creating various blow moulds and injection moulds with the following characteristics: Extrusion blow moulds with volume of the articles up to 20 litres; Injection moulds with a maximum size of 546 mm X 896 mm and a maximum weight of 2,500 kg. We also offer a complete set of services that help in the manufacturing maintenance of mould tools: Design, 3D model and a “Rapid Prototype”; Servicing and repairs.

Request for a quote

REP INTERNATIONAL

France

Economic injection molding presses. A REP injection unit combined with a closing unit of a Tung Yu press. This combined technology offers openended options Separate extrusion and injection thanks to the "Y" type injection unit. 2 or 3stroke closing unit. Proportional closedloop temperature control. Optimized floor space and ergonomics thanks to its modular design.

Request for a quote

KANEKA BELGIUM

Belgium

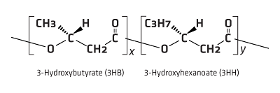

The material can be processed with conventional plastic industry equipment, such as injection molding and extrusion machinery. The typical end applications are those for which organic recyclability (compostable and anaerobic digestibility) is the intended end-of-life or for which it is challenging to avoid fragments ending up in the open environment. It is suitable for (food) packaging, organic waste management, agricultural, horticultural, and marine-related applications.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO can offer PEEK powders in various viscosities. It can be used for a variety of applications: semi-finished product extrusion, injection molding, compounding, filament and film extrusion, coatings. Our CoPEEK 012P is a high viscous, unreinforced PEEK for extrusion and injection molding, thus it is the standard type for the production of semi-finished products. CoPEEK 021P is medium viscous, unreinforced PEEK for injection molding. But it can also be extruded for the production of films and filaments. CoPEEK 085P is low viscous, unreinforced PEEK for the extrusion of films and filaments. It is also used as the basis for compounds and composites. Our CoPEEK can be processed on machines for thermoplastics without any problems. We recommend a processing temperature of 360 °C to 380 °C. BIEGLO CoPEEK is ISO 10993 certified for medical applications and also has FDA certification.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO can offer PEEK granulates in various viscosities. It can be used for a variety of applications: semi-finished product extrusion, injection molding, compounding, filament and film extrusion, coatings. Our CoPEEK 012G is high viscous, unreinforced PEEK for extrusion and injection molding, thus it is the standard type for the production of semi-finished products. CoPEEK 021G is medium viscous, unreinforced PEEK for injection molding. But it can also be extruded for the production of films and filaments. CoPEEK 085G is low viscous, unreinforced PEEK for the extrusion of films and filaments. It is also used as the basis for compounds and composites. CoPEEK 125G is very low viscous, unreinforced PEEK for the injection molding of thin-walled, complex components. It is also suitable for the production of highly filled compounds.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient,practical and functional 2 working stations injection moulding machine for producing compact,extensive,strong,pliable or unpliable,quality shoe soles in 1, 2 or 3 colours from materials such as TR,TPU,TPE and PVC. The main characteristic of the machine is possessing the PLC control.In the machine are used Siemens products.The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable.Heating controls are connected to the PLC device.The machine has full automatic,semi-automatic and manual system.In the cooling system which is accordingly designed, in the three parts water circulation channels are installed. The cooling plates are made of pressed aluminium and the cooling is provided as necessary.Due to the technical characteristics the usage of other machines' molds is possible. With this machine at the cost of the ordinary one colour machine widely used you will get 1, 2 and 3 colours Shoe soles injetion moulding machine.

Request for a quoteResults for

Injection and extrusion - Import exportNumber of results

43 ProductsCountries

Company type

Category

- Polymers (6)

- Granules for plastics (3)

- Sandblasting equipment (3)

- Die casting moulds (2)

- Heating, industrial - installations and equipment (2)

- Plastics - machines and material for industry (2)

- Abrasives, chemical (1)

- Additives for plastics industry (1)

- Chemical industry - machinery and equipment (1)

- Chemicals - Basic Products & Derivatives (1)

- Extrusion, plastics - machinery (1)

- Filtering equipment and supplies (1)

- Foundries, aluminium (1)

- Injection moulding of rubber and plastic (1)

- Machine tools - metal machining (1)

- Plastics - industrial machinery and equipment (1)

- Plastics moulding (1)

- Shoes - industrial machinery (1)

- Silicones (1)

- Stain removers, household (1)