- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- infrared ovens

Results for

Infrared ovens - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our Infrared ovens can be produced as conveyor belt tunnel or internal return (U) type. Our ovens have andirect heating system with radiation heat transfer. They are used due to the cure flat shaped parts after wet or powder coating paint applications. They are preferred because they can cure the paint three times faster than the convectional type ovens. They can be produced with natural gas or lamp type infrareds. The inner surfaces of our ovens’ panels are produced with a galvanizedor stainless steel sheets and the outer surfaces are produced with galvanized sheet steel coated with electrostatic powder paint. Considering the application temperature, the required thicknesses determined and rock wool or glass wool is used for insulation.

Request for a quote

ERATEC

France

Improve existing equipment by integrating our infra-red emitters, with a positive impact on productivity, quality and energy savings. DRYING TUNNELS AND COMBI OVENS For baking, browning, toasting and marking : Biscuits, Bread, Brioche, Toast, Pizza, Pancake, Chips, Chips, Cereals, Meringues... BURNER INTEGRATION EQUIPMENT Deep fryers Kettle Coffee roasting Baking trays Decontamination of cheese crusts

Request for a quote

EUROLINIA

Belarus

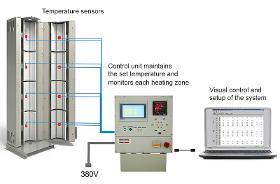

EUROLINIA Industrial Infrared Ovens are designed for high-precision surface heating of various materials and products by directional infrared heat. Precise temperature control, sperate heating zones, custom software for your application. Optionally ovens can be equipped with protective steel curtains for instant heating termination or inertia-free start/stop system. Maximum temperature of the infrared ceramic emitters is 750 °C. Maximum temperature inside the oven is 450°C. Maximum power density on the surface of the heated product up to 30 kW/m2. 380V.

Request for a quote

EUROLINIA

Belarus

EUROLINIA infrared industrial tunnel ovens are designed to rapidly and uniformly heat the surface of cables, wires, polymer pipes and tubes, dry fiber optics and etc. in batch or continuous conveyor production using targeted high-intensity infrared radiation. High efficiency is achieved by concentrating high-intensity infrared radiation and by using a circular reflector that efficiently distributes radiant energy inside the heating chamber. Additional efficiency is gained by installing three-level thermal protection. EUROLINIA tunnels have modular structure: one heating section is 2 meters long, you can connect up to 8 sections in one production line. Maxumum temperarature in the tunnel can reach up to 700C. Tunnels can have multiple separate heating zones and can be equiped with a conveyor. To ensure high-quality, high-precision surface heating, industrial tunnel ovens are also equipped with an automatic heating control system (APCS).

Request for a quote

EUROLINIA

Belarus

EUROLINIA offers custom designed control systems from small single heater controls to large multi-zone systems for reliable, economical, and efficient heater performance to ensure precise process temperature control. Some clients, in order to cut costs, underestimate the importance of using appropriate control systems and, as a result, cannot get effective uniform heating and desired quality of the final product. When we develop a control unit for our infrared heating system – we guarantee that the final product will meet all requirements and expectations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELCON ELEKTRIK OTOMASYON VE ENDÜSTRIYEL ISITMA LTD. ŞTI

Turkey

Before the PET preform is inflated in the mold with compressed air, it is ensured that it reaches a certain temperature by passing through the infared oven. In order for the preform not to deform, the heat setting must be very sensitive. IR technology is very important in pet blowing ovens. The main reasons for this are: - To provide a homogeneous heat distribution on the preform - Since the cover area is thick and the bottom area is thin, the preform needs to be exposed to different temperatures. The most effective method for this is IR technology. - Water, carbonated beverage, etc. The requirement of the companies to respond to the needs makes the machine speed an important factor. Infrared blowing ovens are preferred over indirect heating systems as they perform very fast and effective heating. - Maintenance and repair time is very short. - Maintenance and repair costs are low.

Request for a quoteResults for

Infrared ovens - Import exportNumber of results

7 ProductsCountries

Company type