- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial washers

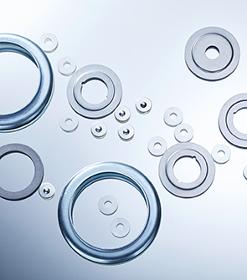

Results for

Industrial washers - Import export

AUROMAK MAKINA

Turkey

Manual washing involves the application of apressurized mixture of water and chemicals. This method is used for cleaning surfaces by manually spraying the pressurized water and chemical solution on to the target area. It is commonly employed for effective and comprehensive cleaning. The selection of appropriate cleaning tools and chemicals depends on the surface condition and cleaning requirements.

Request for a quote

AUROMAK MAKINA

Turkey

Manual washing involves the application of apressurized mixture of water and chemicals. This method is used for cleaning surfaces by manually spraying the pressurized water and chemical solution on to the target area. It is commonly employed for effective and comprehensive cleaning. The selection of appropriate cleaning tools and chemicals depends on the surface condition and cleaning requirements.

Request for a quote

GEYSER LLC

Russia

An automatic washer is designated for: - Returnable containers washing and cleaning - Plastic tanks washing (household waste trash containers) - Boxes and trays washing - Pallets and platforms washing Washing capacity is 100-900 boxes per hour. The washer dimensions can vary for different size of the returnable container. The АПУ 400K washer allows you to clean plastic boxes of E1, E2, E3 and E4 standards. The automated unit allows you to wash any plastic and metal containers and equipment as follows: tanks, bread trays, boxes in meat production and milk containers, household waste trash containers and pallets. The device may include washing unit, rinsing and drying units. The washer is equipped with a conveyor, a control cabinet, assembly compartment, tubular electric heating element, a temperature sensor and a solution level meter. The conveyor speed is individually adjustable and can reach several meters per minute.

Request for a quote

GEYSER LLC

Russia

A washing unit with manual cleaning designated for complex cavities, soot dirt and carbon deposits. It is guaranteed to remove: cooling mixtures, dust, shavings, composites, oils after stamping, rust-preventing grease, polishing compounds, emulsions, oil products, sweat and grease deposits. The unit allows you to clean parts with complex cavities. A washing unit is equipped with a pneumatic drive for connecting a pneumatic brush and an air gun, as well as a flexible hose for supplying water under pressure.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK Carbon Reinforced Washer Discover unparalleled resilience and enduring strength with our Carbon-Reinforced PEEK Washer. Engineered for industrial-grade reliability, this washer is meticulously crafted to withstand rigorous applications. With customizable dimensions, it ensures a precise fit, elevating machinery performance and longevity. Count on its superior durability to meet diverse industrial needs with unwavering resilience.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

DOLFİN- VDL series Drum (Spiral) parts washing machines are used especially for cleaning small parts with high production quantities and produced in bulk. The materials poured from the inlet part of the spiralised drum in the device are directed towards the outlet part of the drum by the spirals inside the drum. While the drum moves on its own axis according to the set rotation speed, the parts are subjected to washing (degreasing), rinsing, passivation and drying processes respectively (depending on the model). Since these processes are sequential and continuous, all processes are completed quickly and effectively in a single device. Full penetration is achieved by pressurised spraying and immersion effects in each section. It is a very functional model used especially for washing bolts, nuts, washers, or small parts of this type, and fittings, nipples, couplings and fittings processed in high quantities on cnc and automat machines.

Request for a quote

BKM PRÄZISIONSWERKZEUGE STANZ UND BIEGETEILE GMBH

Germany

EUROMACK

Turkey

AREAS OF USE - Automotive industry - Aircraft industry - Ship industry - Defense industry - Metal industry PRINCIPLE OF OPERATION The parts to be washed on the basket placed on a stainless rotary platform with a sliding system are subjected to rotary basket washing with water with high pressure detergent in a closed cabin to be placed. Washing process is carried out to clean oil, sawdust, dirt and waste from dirty surfaces from different angles by means of time-adjustable pressure water nozzles according to the part structure and pollution rate. By filtering the water with the cycle permanent system, it is designed to reduce the consumption of water, detergent, electricity and time (labor) with the least consumption of parts. OPTIONAL FEATURES - Steam Evacuation Unit - Stainless chrome body structure - Basket structure - Number of nozzles - Liquid level control system All kinds of parts washing machines can be manufactured in our company upon request.

Request for a quoteResults for

Industrial washers - Import exportNumber of results

9 ProductsCountries

Company type