- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial tool manufacturer

Results for

Industrial tool manufacturer - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

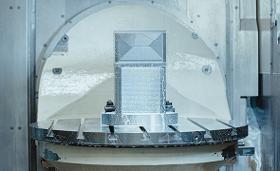

In precision grinding, maintaining tight tolerances and perfect surface structures is crucial. The demands in this area have increased, challenging both grinding tool manufacturers and producers. Tyrolit meets these requirements through innovations in precision grinding wheels, distinguished by extensive process know-how and pioneering consulting services. We serve a wide range of industries, including tool manufacturing, automotive, steel, turbine, and medical technology, always adhering to the principle: accuracy is key! Tyrolit offers standardized application technology advice and process support at the highest level. Our expert team, with years of experience, provides constant support. Employees across various countries are closely linked with our headquarters in Austria, ensuring qualified technical support for all precision grinding applications, such as external and internal cylindrical grinding, surface and creep feed grinding, or honing.

Request for a quote

PJM MECHANICAL CO.,LTD

China

Low Backlash: Backlash is under 3 arcmin.Backlash for 2 stage speed reduction is within 5 arcmin High Efficiency:Efficiency for 1 stage model exceeds 95%,2 stage model exceeds 92% Size:PLF060/PLF080/PLF090/PLF120/PLF160 Output Rated Torque Range:From 9Nm to 500Nm Adapter-bushing connection,can be attached to any motor No Grease Leakage and Maintenance-free Planetary Gearbox Application:Aerospace,military industry,Medical health,electronic information industry,Industrial robots,production automation,CNC machine tool manufacturing industry,Auto industry,textile,printing,food,metallurgical,environmental protection engineering,warehouse logistics industry

Request for a quote

MOH D.O.O

Slovenia

components for making tools for Rubber injection plastic injection high pressure aluminium injection moulding low pressure injection components for making cutting tools components and construction of clamping devices housings holders

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

APEX TOOL GROUP GMBH

Germany

Compact, light, tough Cleco® updates the product range of pneumatic impact wrenches with a new mini compact model with 1/2" drive. The CV series is a universal impact wrench, designed for industrial production, repair and maintenance. Lightweight, balanced and with a comfortable design, the CV series provides fastening performance at an unbeatable value. All impact wrenches of the CV series are equipped with a powerful twin hammer mechanism. Also available in the common drive sizes 3⁄8-, ¾- and 1 inch. All advantages of the new Cleco® CV-375R-4 at a glance: - High-efficiency air motor - Twin hammer impact mechanism - Variable speed trigger - With ring anvil - No-charge modular muffler system - Max Applied Torque – 560 Nm - Max Breakaway Torque – 690 Nm - Free Speed – 8000 RPM - Lenght 157 mm - Weight 1,3 kg - Impacting Sound Level* 87 dB(A)

Request for a quote

APEX TOOL GROUP GMBH

Germany

Cleco's Right Angle Grinders meet the challenging requirements of many industries. They feature a high-performance 1,25 kW motor, to maximize material removal rates for the most demanding applications. The Right Angle Grinders’ internal components are built to last long, and are protected by a dual-layer, high-impact housing providing extreme durability. The most important informations: -Available in 100, 115 and 125 mm disc sizes -Versatile 270° adjustable guard -Intelligent Spindle lock for quick and easy abrasive changes -Quieter operation with rear exhaust overhose standard -Ergonomic, anti-vibration handle for increased comfort and less operator fatigue -Designed to fit all Type 27, Type 27 threaded hub and Type 1 abrasive discs

Request for a quote

KRAMSKI GMBH

Germany

In stamping technology, many very different technologies can be integrated into the stamping process, such as assembling two or more parts, contact riveting, resistance and laser welding, laser marking of parts, or thread forming. Our high-precision tools, thereby, create a basis for production that is, over its lifetime, very high quality and economical. The stamping process is accompanied by a 100 % quality control of the functional design dimensions.

Request for a quoteResults for

Industrial tool manufacturer - Import exportNumber of results

9 ProductsCountries

Company type