- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial steam generators

Results for

Industrial steam generators - Import export

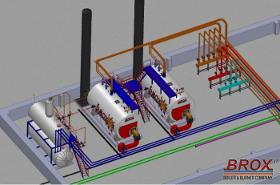

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

1 ton/h to 18 ton/h Industrial Fire tube Steam Boiler, generating superheated or saturated steam, fired Gas, Liquid and/or Solid fuels, turnkey project flexible solutions as per customer demand.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

When operating with green energy, the boiler allows your company to achieve a CO2-neutral steam supply. — Generate up to 7.5 t/h steam in a highly efficient way using just electricity – no combustion, no emissions — High steam quality, excellent dynamics, full flexibility — Reduced expenditure: No flue gas, no fuel supply — Application-specific design and particularly reliable operation — Smart boiler control and seamless system integration — System equipment and service from a single source

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With impressively low emissions and its ability to be converted for biofuels or hydrogen, the UL-S is designed to be future-proof. — Very high efficiency for low running costs and emissions — Complete system with customer-specific equipment and future-proof technology — Extremely well proven design “Made in Germany”, highly durable and easy to maintain — Consistent steam quality for reliable supply — Custom designs available for heat recovery boilers, hybrid or superheated steam — Smart boiler control and seamless system integration with digital assistants

Request for a quote

SCHARFF TECHNIEK

Netherlands

The right choice for your application(s). We not only distinguish ourselves by high-quality products, but we are involved. We are on site during all phases of delivery and installation to ensure that everything runs smoothly and according to your wishes. CERTUSS steam generators are of high quality and generate boiler efficiencies of up to 98%. They have been developed from innovative standards, according to PED guidelines, i.e. the latest applicable regulations. And as required, the steam boilers are TUV-approved and provided with a CE certificate, which means that our product complies with the applicable

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

Thanks to the sanitizing power of the MK2000 steam generator it is possible to clean surfaces, equipment and environments in an ecological way, avoiding the use of chemicals. Its powerful steam jet is effective wherever you need deep cleaning and a high level of hygiene. Thanks to its lightness and small size, MK2000 is perfect for all different types of environments.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

Thanks to the sanitizing power of the MK5 steam generator it is possible to clean surfaces, equipment and environments in an ecological way, avoiding the use of chemicals. Its powerful steam jet is effective wherever you need deep cleaning and a high level of hygiene. Thanks to its lightness and small size, MK5 is perfect for all different types of environments.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

2 outlets at 10 bar with detergent dispensing Steamy is a 10 kW steam generator. It is equipped with one or two steam outlets and with a professional vacuum cleaner on request. The rear tanks can be connected to a water source for continuous steam production. Available in 7 different versions.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

1 outlet at 10 bar with detergent dispensing Steamy is a 10 kW steam generator. It is equipped with one or two steam outlets and with a professional vacuum cleaner on request. The rear tanks can be connected to a water source for continuous steam production. Available in 7 different versions.

Request for a quote

SCHARFF TECHNIEK

Netherlands

Clean Steam, clean steam, culinary steam or pure steam, maybe one of these terms sounds familiar to you. Never heard of it, and do you work in the food pharmaceutical or chemical industry? Then it is especially important to read the following information. On this page we briefly explain the difference between different types of steam. That can make all the difference for a safe end product. Steam is an extremely widely used product in many different industries. For example, most of our customers in the food industry use steam in the production process where it comes into direct contact with their food product. For example, soups and sauces are heated by the direct injection of steam. In this case, the quality of steam becomes important. There are different types

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

With the new EMX model range of electric steam boilers, CERTUSS offers you twice the steam output as before with a significantly smaller footprint. Electric steam generators from CERTUSS are heated by stainless steel heating rods with a large heating surface. The output of the heating elements is regulated continuously via semiconductor contactors. One energy-efficient advantage is the immediate modulating output adjustment to the actual steam demand during the operating cycle. For greater steam demand of up to 640 kg/h or fluctuating steam loads, several ELECTRO steam generators can be cascaded in series. Multiple systems like this are an especially economical solution. Our compact electric steam systems feature built-in feed water tanks and feed water pumps. They require very little space and have a short heat-up time. Steam systems are also available as a unit with water conditioning equipment installed at the factory.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The new generation of a proven series. The CERTUSS Universal 500 - 1800 TC steam generators are characterized by the immediate modulating output adjustment and the simplified operation. TC is the abbreviation for Touch Control. CERTUSS steam generators of the Universal series with oil, natural-gas or combination combustion are manufactured in four sizes. Individually or combined they meet all requirements and dispose of lightened official installation conditions in Germany. Combustion: Oil, gas or a combination Steam output optionally 500 - 600 kg/h 700 - 850 kg/h 1,000 - 1,300 kg/h 1,500 - 1,800 kg/h

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

Our steam generators are available on request as a ready-to-operate steam boiler plant: CERTUSS steam generator plus CERTUSS supply unit CVE. All components for the water supply and water conditioning of the CERTUSS steam generator are included in the complete steam plant. - Feed water tank - Desalination heat exchanger - Water softening equipment - Test extraction cooler - Mixing heat exchanger - Measuring equipment - Steam dryer The CVE supply unit is compatible with all the CERTUSS steam generators. In addition to the CERTUSS supply unit as a ready-to-operate boiler house installation on a basic frame, we also offer a complete container installation on request. Depending on the desired steam output a multiple steam boiler plant may be suitable for you.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The electrical steam generators E 100 M – 120 M from CERTUSS offer you impressive output in two output capacities of 100 - 120 kW heat output. They are compact, economical and have a high output. All electrical versions do not require a permit for installation and use in Germany. Heating: Electrical heating rods Steam output 135 – 160 kg/h The sizes: E 100 and E 120 - In two output capacities of 100 - 120 kW heat output. - Fully electronic pressure and output control. - Compact stainless steel heating rod with low heating surface load, placed laterally on the pressure body for easy access. - Constant network load without consumption peaks. - Integrated multifunction display. - Multilanguage plain text indication.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The electrical steam generators E 6 M - E 72 M from CERTUSS offer you impressive output in 14 different output sizes. They are compact, economical and have a high output. All electrical versions do not require a permit for installation and use in Germany. Heating: Electrical heating rods Steam output 8 - 97 kg/h The compact: E 6 M – E 72 M - In 14 different output sizes. - Easy-to-service compact device – easy to operate. - Direct access to all parts from the front for easy maintenance. - Fully electronic pressure and output control, immediate load adjustment. - Function and malfunction indications can be linked to central control system / building services control system provided by - customer. - Low space requirement, reduced and robust heavy-duty model in elegant design. - Fully automatic operation by means of time control or remote pulse (optional). - Automatic clarification and desalination (optional).

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The small steam boilers of the Junior 80 - 400 TC series are completely equipped, ready-to-operate, electronically controlled rapid steam generators with all safety devices for burner technology, pressure and temperature. With a height of only 1.5 m and 0.7 m width the Junior 80 TC steam boiler can be erected even in small spaces. Combustion: Oil or gas Steam output optionally 80 - 120 kg/h 150 - 200 kg/h 250 - 400 kg/h

Request for a quote

GAICTECH

Spain

The Tuna Fish Steam Cooker is expertly designed to refine the production process for tuna, focusing on increasing total fish yield through precise thermal gradient control and moisture content preservation. This ensures the fish remains moist, facilitating easier cleaning post-cooking. Tailored for flexibility, it offers adaptations for client-specific trolleys and the option for cooking without vacuum, enhancing its utility in diverse processing environments. Remote support capabilities allow for diagnostics and adjustments via PC and Ethernet, ensuring seamless operation and troubleshooting. Constructed from high-quality stainless steel AISI 304 L, the cooker is built for durability and hygiene compliance. Key features include a fully automatic cooking cycle, options for time or temperature-driven cooking directly in the fish's bone, and advanced process control via the latest generation PLC with exclusive tuna cooking programming. Temperature monitoring through thermocouple

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

18-20% fuel saving, efficient steam generator, generating steam in 3 to 5 mins. Due to it is modular design, number of generator in system can be specified as per customer steam demand and the generators starts and stops according to steam consumption.

Request for a quote

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

Fast Steam Generator, designed as Vertical or Horizontal, generating steam in 3 to 5 mins after cold start-up, Gas & Liquid fuels options.

Request for a quote

ENEVA ENERJI SISTEMLERI MUHENDISLIK SAN TIC LTD STI

Turkey

Indirect steam generators are used to produce saturated or superheated steam indirectly, using higher pressure steam, thermal oil or another heat carrier which already exist in the plant. By doing this way there will be no need for additional boiler room investment. (Fuel piping, chimney etc.) ISG type steam generators operates with primer fluid flowing inside tube bundles and seconder fluid (steam) produced outside of the bundle. Thanks to flanged design, tube bundle could be disassemled completely and easily for renewing or maintenance purposes. ENEVA can supply completely stainless steel indirect steam generators named “Clean Steam Generator“ or “Hygienic Steam Generator “ for medical sector or food processing plants.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

For the construction of its steam generators, Büttner uses the experience in steam boiler construction established at the end of the 19th century and combines this with modern technology, guaranteeing safe and protable facility operations Key features: Indirect steam generation with thermal oil Direct steam generation with ue gas from biomass combustion Debrators or reners, wax smelters, sifters and heating for buildings are just some of the applications for steam generators. Design, construction, assembly and inspection of steam generators in compliance with EN, ASME or GOST norms

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Steam is a pressure vessel manufactured to store excess steam or waste vapors out of the operation of aquaria and to be used again when necessary. They are mainly used in gas concrete installations especially for the purpose of recovering the waste steam from the process. There are water and vapor phase zones in the steam chamber. The volume is 4/3 water phase. Steam The steam is stored in the battery in the hot water phase by injecting the steam into the water by means of the diffusers located below the water level and dissolving it in the water. When the steam is needed, the pressure of the hot water is lowered and the steam produced by the resulting phase change is transferred to the process to be used again. Using a steam bath; Up to 25% energy saving is achieved. They can both discharge steam and discharge at the same time. Suspended solid materials which are dragged together with the steam collapse under the liquid and the bluff is removed from the environment and the steam is

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Steam boilers with water pipes are boilers in which the water circulates and evaporates in the pipe. This high-capacity, high-capacity, high-capacity steam boiler. The combustion chamber is surrounded by a pipe-pipe-pipe joint. As a fuel in water pipe steam boilers; They use solid fuel, liquid fuel and gas fuel. n terms of safety, the water is more secure due to circulation in the pipes. Because of their lower water volumes, they are boilers that enter the regime more quickly.

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

They are high-quality steam generating equipment used in all industrial plants to obtain steam required for processing. Steam boilers with flame smoke pipes can be produced as flat ashtrays and hot ashtrays. Solid, Liquid and Gas fuels are used as fuel type. Eralp Makina Kazan In 2005, it is proud to be the most productive employee of Turkey with double economy working with natural gas (total system efficiency = 98,4%). Yield tests of our product produced by Yildiz Technical University and ISKAV Foundation.

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Thanks to large contact surface of water with smoke pipes, high operational safety and longer boiler life are guaranteed. The small water volume provides a better inside circulation and safe heat transfer with faster steam generation time. Increased strength and flexibility with corrugated furnace that is manufacturing by Eralp in 900°C degrees. In 3-pass Shell boiler design, the heat load of furnace is less than 1,2 MW/m. The result of this design is an ideal combustion with less NOx emissions, thus it causes lower fuel consumption. Further gains in efficiency can be obtained by using economizer for feeding water by preheating and air-heater for combustion air heating. The energy of flue gas can be recovered and the efficiency of boiler system is increased 5-8%. According to pressure of boiler, efficency increase up to %91. Eralp manufactured the highest efficent boiler (totally efficiency=%98,4) with two economisers which efficency tested and approved by Notify Body.

Request for a quoteResults for

Industrial steam generators - Import exportNumber of results

26 ProductsCountries

Company type