- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial components

Results for

Industrial components - Import export

MOH D.O.O

Slovenia

components for making tools for Rubber injection plastic injection high pressure aluminium injection moulding low pressure injection components for making cutting tools components and construction of clamping devices housings holders

Request for a quote

METAL IN LTD

Bulgaria

The company is subcontractor of metal details and components of furniture industry, as some of the main products are: metal construction for tables Folding mechanism for beds, sofas and stools Medical beds with adjustable height А device for lifting patients Feet for tables, sofas and stools Feet for tables, sofas and stools Bunk beds Beds and desks that fold to the wall Mechanisms for lifting and lowering of the mattress Metal cabinets Metal boxes

Request for a quote

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy. Types of products we manufacture Glass coaters and packaging machines in the vacuum industry Baseplates and chassis for the oil & gas and energy industries Winches and crane components for the naval industry Pressure vessels from carbon steel and stainless steel PROJECT MANAGEMENT DESIGN & ENGINEERING CUTTING ASSEMBLING & WELDING PRESS BREAKS FOR BENDING ROLLING MACHINING HEAT TREATMENT SURFACE TREATMENT FINAL ASSEMBLY & AUTOMATION CUSTOM PACKAGING & DISPATCH

Request for a quote

MÃO DE FOGO

Portugal

Sand Casting For simpler sculptures, without a great degree of detail, we are equipped with equipment to produce sculptures using the chemical sand process. Finishing The chemical sand casting process uses a chemical binder to unite the sand grains and form the mold and allows parts to be obtained with good dimensional accuracy and surface finish. Materials It is used to smelt various metals such as iron, steel, aluminum, copper or bronze. The pieces can have various sizes and complex shapes. Shapes It is used for the production of automobile components, agricultural machinery, industrial equipment, decorative items, furniture and works of art, such as sculptures, busts, plaques, trophies, etc.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer Custom Homogenizing Rods for use within Fluorescence Imaging. Knight Optical supply precision optical components to customers in the medical industry for applications such as fluorescence illumination, microscopy and imaging. Homogenizing Rods are used within the application of surgical procedures; within systems designed to help identify which tissues have been exposed to the fluorescent indicator. The Light source will enter a light pipe at a variety of incident angles, which is designed to utilise its total internal reflection to channel the light from the entrance of the light pipe to the exit. The material’s refractive index is the only factor which affects the light pipes critical angle; this defines the angle of acceptance which the total internal reflection will occur at. With this it helps to control the light source being used in medical systems. Read PDF for more info

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Application SMT, BGA, CSP, Flip Chip, LED Detection, Semiconductor, Packaging components, Battery Industry, Electronic components, Automotive parts, Photo-voltaic, Aluminium Die-casting, Moulding Plastic. Ceramics, other special industries.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer Cube Beamsplitters for use within the Scientific Industry. We supply a range of Cube Beamsplitters for a range of applications. All individually QA checked and metrology tested for quality to ensure parts meet customer specification. Supplied in a range of sizes and shapes with custom coatings tailored to meet your individual applications. Knight Optical supply precision optical components to customers in the scientific industry for use as components within spectrophotometers and interferometer. For interferometry, beamsplitters are used to separate light into two beams to compare a reference against a sample. Cube beamsplitters offer some advantages over plate beamsplitters in that they don’t suffer from ghost images and are easier to mount. For more information read PDF…

Request for a quote

GRONBACH

Germany

Gronbach manufactures decorative elements for the automotive industry in interior and exterior areas such as trim strips or trim parts made of aluminium, stainless steel and plastic hybrid technology. Functional components and plastic injection molded parts with a focus on fan wheels and turbines are also essential components of our technologies. As a specialist for surface finishing, you have a wide range of colours (anodising, powder coating), noble shapes and surfaces (brushing, grinding, polishing, blasting) and high-quality individualisation (screen printing, pad printing, under-anodising printing, laser engraving, etching techniques) at your disposal. In addition to the production of individual parts and the manufacture of complex assemblies as well as end products, we also offer you as a system supplier the complete project planning for new developments. Our portfolio includes: Automotive door sills Interior visible parts, e.g. side applications, decorative panels and...

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Service Cleaning: Our customers count on our contract cleaning team for their daily cleaning needs -. With modern cleaning processes e.g. thermal with pyrolysis, aqueous with ultrasonic or mechanical with lapping blasting we can clean and improve your high quality tools. Whether extrusion or injection molding tools, extruder screws, hot runners, nozzles, filters, molds, screens, adhesive or coating devices - everything will be cleaned by us for you! Detailed advice and documented cleaning of samples ensure consistent results over a long period of time. Test us - In addition to comprehensive advice, we offer you the opportunity to carry out your own cleaning trials of workpieces up to a length of 3 m and / or 4 t in weight. Cleaning trials: Every customer can convince himself of our offer by a free sample cleaning. Whether cleaning, surface treatment or decoating - with us you as a customer can see the result even before the first order!

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® MT micro blasters are used for precise blasting with blasting nozzles from 0.4 – 1.8 mm. Surfaces can be smoothed, matted, deburred or cleaned. All mineral media, e.g. glass beads, broken glass, corundum, silicon carbide in the grain size range from 0 to 300 mμ serve as blasting media. The abrasive is used only once. The blasted surface is reproducible. Only a compressed air connection is required to operate the equipment. Micro-Tip fine blast units are suitable as portable free blast units or in combination with a blast cabinet. Micro-Tip fine blasting technology is available as a pressure or injector process. All units are equipped with foot pedal, pressure regulator, manometer and carbide nozzles.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® PYRO paint stripping and decoating oven for particularly large and heavy batches. Particularly powerful furnace technology for the highest demands. With state-of-the-art IPC control and industrial burner technology. This furnace series enables clean, reproducible process parameters as well as state-of-the-art exhaust gas treatment.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Thermal cleaning in the WIWOX® IGS thermal system at up to 500° C removes all organic residues, even from fine bores. Depending on the melting and decomposition point of the residues, they are either melted or pyrolysed. The resulting exhaust air during the carbonization phase is burned in the afterburner chamber at over 850° C. Cleaning in the pyrolysis process requires subsequent post-cleaning. Inorganic components, oxidation residues, corrosion, etc. remain on the tool surface and must be removed. The ultrasonic process with acidic or alkaline cleaning media or the blasting process with organic and mineral abrasives are suitable for this purpose.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® Spintec top loader spray chamber washing systems are the solution for fast parts cleaning in maintenance! The parts to be cleaned are placed in the washing basket of the system from above. During the washing process, cleaning fluid is sprayed onto the parts from below, above and from the sides. The basket rotates inside the machine, resulting in an even washing result. The detergent reservoir is located in the bottom of the machine and is also equipped with a heater.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® VIVERK are single and multi-stage spray chamber cleaning systems for aqueous cleaning, pretreatment and degreasing of tools and parts. Loading takes place via an extendable platform, which can be loaded at an ergonomic working height. The workpieces are mechanically cleaned by means of pump pressure in the spray chamber process. The temperature-controlled washing liquid is sprayed onto the workpiece via a spray frame.The washing plant is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Single and multi-stage spray chamber washing systems for industrial cleaning and degreasing of tools and parts. Loading takes place via an extendable loading platform at ergonomic working height. Before cleaning, the loading basket is loaded and moved into the rinsing chamber. The individual stainless steel washing nozzles can be easily maintained and adjusted according to the application. The motor-driven spraying rotor completely revolves around the loaded parts. The washing system is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

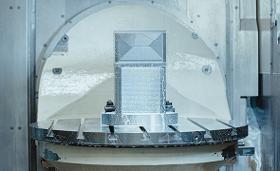

WIWOX® DP-EU pressure blasting cabinets clean and process tools and parts in just a few seconds. Fine blasting granulates are shot onto the surface by means of compressed air and remove dirt and corrosion. The blasting nozzle is manually guided during the processing of individual parts. Process automation is also possible. For this purpose, the workpiece or the blasting nozzle is moved by motor. The pressure blasting process is suitable for the removal of all solid, exposed residues and layers, especially on metallic surfaces of production tools and high-quality machine parts. Deburring and finishing of surfaces is also possible. In extensive tests with your tools you can convince yourself of the economic efficiency of our system. We will provide you with a test facility for this purpose after consultation.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DI-EU injector blasting cabinets are designed for use in production and maintenance. Ready for use equipped with integrated cartridge filter and abrasive recovery system. Economical operation with fine-grained abrasives with low air consumption of approx. 800 l/min. at 6 bar blasting pressure. The blasting media is continuously sucked out of the cabinet by a constant negative pressure and separated from dirt and dust in a downstream cyclone. A cyclone screen (possibly with ring magnet) collects coarse impurities. In this way, only clean abrasive remains in circulation. The used abrasive, dust and small impurities are led through the cartridge filter chamber to the dust collecting bucket.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® 410 is a liquid, alkaline mould cleaning agent for the removal of burnt rubber and plastic residues from metallic surfaces. It is also used as a paint stripper. WIWOX® 410 is used undiluted for immersion cleaning of metal moulds. The construction material for the tank can be sheet steel or stainless steel. The tank size depends on the moulds to be cleaned. The pool can be heated from the outside or inside by a heating coil. The processing temperature is generally approx. 80° C. The processing time depends on the degree of soiling and the type of soiling between 10 – 30 minutes.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® 340 is a weakly alkaline cleaning agent for grease, oil and oil carbon soiling. Very suitable for pre-cleaning or basic cleaning of soiled steel, cast iron and non-ferrous metal or plastic parts in an ultrasonic bath or in a spray cleaning system. After cleaning and without water rinsing, the parts are temporarily protected against corrosion. The final drying can be accelerated by blowing off with compressed air, a warm air flow or treatment in a drying cabinet. WIWOX® 340 can be used in a concentration of 5 – 7 %. Dilution with water depends on the degree of contamination and the intended exposure time. The bath should have a temperature of approx. 60° C. The bath should be kept at a constant temperature. In the field of precision mechanics, longer exposure times are possible depending on the degree of contamination.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® 250 is a very alkaline cleaning concentrate for organic (oil, coal, grease etc.) and inorganic (magnesium, lime etc.) residues on tools and moulds. It can be rinsed off residue-free without a film on the surface. The concentration depends on the working conditions, the degreasing time, the degree of soiling, etc. (between 5 – 30 %). Regular replenishment by checking the bath can prolong its service life. In contrast to powder concentrates, lthe iquid formulation allows convenient use without danger of exothermic reaction in the plant.

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm.Pharmaceutical and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

GRONBACH

Germany

In addition to complete OEM devices, Gronbach produces a wide range of mechanical components for the household appliance industry, which are characterised by dimensional accuracy and durability. Our products can be used both in the visible area of kitchens and gastronomic facilities and as ready-to-install functional components. We develop and produce material- and production-optimized according to your specific requirements. In addition, we develop and produce material- and production-optimised designs of assemblies according to individual customer-specific requirements, e.g. hinges, front panels, frames and pull-outs, and assemble these ready for installation. We realize small series of special products as well as large series.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and ring gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / ring gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible. Saves time and money. Cooperation with companies for special cases. We are looking forward hearing from you.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC milling machining orange anodized aluminum component for industrial use

Request for a quote

SRL

Italy

Among the many services that we at Alaia Serramenti srl offer you there is also laser cutting. It is one of the most advanced technologies in the field of metalworking, which allows you to obtain very high quality results, precise to the millimetre. The latest generation laser cutting equipment present in our headquarters in San Cipriano d'Aversa allow us to create complex shapes quickly and completely efficiently, unlike what happens when traditional processing techniques are adopted, usually characterized by very long production times, With our technologically advanced machinery we are able to cut materials of any type and thickness, offering excellent services to different production sectors. For example, we have established important partnerships in the field of the production of components for industry and the creation of prototypes for design.

Request for a quote

AAAGILER GMBH

Germany

When time is most critical factor: Facing unplanned equipment downtime? We are the right wholesaler for very urgent deliveries of industrial supplies, machine parts and components across Europe ... If we do not have it, we look for it. Express Industrial Parts Delivery: Sometimes you need a part or component very urgently in order to continue production. E. g. if you have a breakdown of a machine in your production line and you need to certain part from you German, Austrian or other European supplier to repair it. Sometimes German or other European suppliers as well as online shops do not supply to third countries. We have the right solution for you: As a industrial wholesaler we can procure the missing parts on short notice and then deliver them directly to you.

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

Production of elastic and plastic components for all industrial sectors up to racing technology. No matter if single piece - sample production - small series - large series or the production of prototypes. Almost EVERYTHING is possible - and this means from the smallest miniature component (Ø 1 mm) up to large parts (currently Ø 2500 mm).

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

Production of elastic and plastic components for all industrial sectors up to racing technology. No matter if single piece - sample production - small series - large series or prototypes. Almost EVERYTHING is possible - and this means from the smallest miniature component (Ø 1 mm) up to the large gasket (currently Ø 2500 mm).

Request for a quoteResults for

Industrial components - Import exportNumber of results

139 ProductsCountries

Company type

Category

- Pipe and tube fittings - ferrous metal (10)

- Sandblasting equipment (10)

- Control boxes - electric (9)

- Automation - systems and equipment (8)

- ELECTRIC EQUIPMENT (8)

- Pumps (4)

- Precious and semiprecious stones and pearls (3)

- Chemical metal treatment (2)

- Electric motors and parts (2)

- Electronic components (2)

- Forming - steels and metals (2)

- Industrial tools (2)

- Light-emitting diode LED (2)

- Metal furniture (2)

- Metal industrial presses (2)

- Seals (2)

- Sensors (2)

- Siliceous limestone bricks (2)

- Stamping - steels and metals (2)

- Adjustment - machine tools (1)