- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- induction brazing

Results for

Induction brazing - Import export

WIGTEC FISCHEREDER KG

Germany

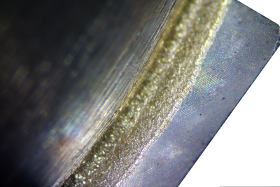

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

MARXAM PROJECT

Poland

Our spot welders allow the use of alternative methods of joining metal elements. Resistance spot welding is one of the most popular techniques for joining thin-walled metals. The use of condenser welding machines allows for quick and easy mounting of fasteners (pins, screws, pins) on the surface of metals. Induction welding allows you to significantly reduce energy consumption, and thus reduces the cost of manufacturing details. This process significantly reduces the area of thermal action, which contributes to easier cleaning of the joined areas. Induction welding technology allows for its automation, which makes the process repeatable and simpler (and therefore cheaper). Thanks to the use of alternative methods of joining materials, we are able to offer our services in the construction industry; transport of liquids and gasses; automotive industry and machine manufacturing.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

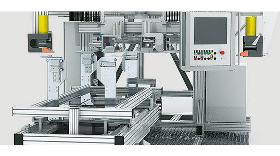

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

SEIT ELETTRONICA SRL

Italy

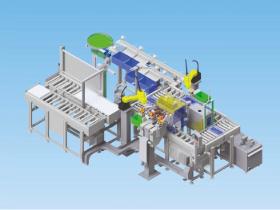

Platinum HUB is a scalable platform you can customize according to your brazing process. You can set up the layout adding multiple stations to: flux, apply brazing paste or pre-formed brazing alloy, wash, dry and cool the parts you are processing, mark with galvo laser technology, and automatic loading and unloading the line using co-bot or industrial robots. This system will for sure adapt to your process and needs and will give you the chance to expand it and add new functions when you really need it. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fits with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the key data from your production as cycle time, temperature and more.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CONTI THERM S.R.O.

Czech Rep.

Induction heating of our CONTI type series is intended for for various applications of treatment such as brazing, melting, stamping, forging, hardening, annealing, tempering, straightening, and bonding –but especially for the heating of conductive metal materials. This rare technology is based on the creation of heat directly inside the worked-on product and it enables the use of the highest level of automation.

Request for a quoteResults for

Induction brazing - Import exportNumber of results

7 ProductsCountries

Company type

Category

- Induction heating systems (4)

- Brazing - steels and metals (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Brazing - equipment and supplies (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Vacuum cleaners - industrial (1)

- Welding work - steels and metal (1)